1~22 item / All 22 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~22 item / All 22 items

Amano Grinding Industry Co., Ltd. [Aichi Prefecture] is a technical group specializing in various grinding processes. We have made it possible to challenge mirror polishing using surface grinding machines! 【Introduction of Processing Samples】*Images 1 to 3 ◎Material: SKD11 ⇒ Compared to conventional grinding, we have achieved a mirror finish that is almost like a mirror. 【Strengths of Amano Grinding】 ● Extensive experience in large to small items, prototype and regeneration grinding, and difficult processing, especially for single items. ● We receive praise for our "short delivery times*" and "high quality." *Fastest: Processing starts from the time of drop-off, minimizing wait time. ● Our responsiveness and willingness to take on challenges are supported by both sales and technical teams. *Please feel free to contact us for more details.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company, Amano Grinding Industry [Aichi Prefecture], is a technical group specializing in various grinding (abrasive) processes. In May 2022, we newly introduced an ultra-large gantry-type surface grinding machine! 【★Newly Introduced Equipment】 ◆ Manufacturer: Nagase Integrex (NAGASE) ◆ Machine Name: Gantry Surface Grinding Machine 'SGD-3010' ◆ Specs: Magnetic Table: 3000×1000, Gantry Width: 1125, Height: 500 ⇒ Capable of R grinding with the surface grinding machine, as well as end face and taper grinding using vertical axis grinding wheels! ⇒ Also able to handle grinding for "motor core molds for EV vehicles," responding to further needs! *These molds are considered to have high processing difficulty due to the coexistence of different materials on the processing surface. 【★Strengths of Amano Grinding】 ● Extensive experience in large to small items, prototype and regeneration grinding, and difficult processing, particularly for single items. ● Recognized for "short delivery times*" & "high quality" *Shortest; processing starts from the time of drop-off with no waiting time. ● Strong support and challenge capability backed by sales and technical teams. ~ We are currently publishing a photo document summarizing various grinding and abrasive processing examples ~ You can view it immediately from the following [PDF Download]. *Please feel free to contact us for more details.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Amano Grinding Industry Co., Ltd. [Aichi Prefecture] is a group of experts specializing in various grinding (abrasive) processing. From small to large items, including cylindrical, flat, and internal grinding, you can trust us with everything from single-item processing of iron to ceramics and carbide! ~ We are currently publishing a photo document summarizing various grinding and abrasive processing examples! ~ You can view it immediately from the [PDF Download] below. 【★ Strengths of Amano Grinding】 ● Extensive experience in large to small items, prototype and regeneration grinding, and difficult processing, especially for single items ● Praised for "short delivery times*" & "high quality" *Shortest; processing starts from the time of drop-off ● The responsiveness and challenge capability supported by sales and technical teams 【★ Future Focus Themes】 As electric vehicles become mainstream, "motor core molds" will become one of the essential molds in future motor production lines. However, these molds have different materials coexisting on the processing surface, making them challenging to work with. ⇒ In anticipation of the increasing demand for motor core molds, we introduced a large flat grinding machine measuring 3000L × 1000W × 500H in April 2022! We will meet our customers' further needs. *Feel free to contact us for a consultation!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding (sharpening) processes. With short delivery times and high quality as our strengths, we respond to our customers' needs. We would like to introduce a case study of our "Mold Restoration Grinding"! 【Is there an increasing demand for motor core molds due to EV adoption?】 As carbon neutrality pushes electric vehicles to become mainstream, motor core molds will become one of the essential molds in motor production lines in the future. However, the processing surface consists of two materials, SKD11 and carbide, making it a mold with a high level of processing difficulty. ★ In April 2022, we plan to introduce a larger flat grinding machine measuring 3000L × 1000W × 500H, anticipating future carbon neutrality! We will continue to meet our customers' growing needs. 【Restoration Grinding Case Study】 ■ Size: 1200 × 600 ■ Product Name: Motor Core Mold for EVs ■ Material: SKD11 and Carbide ■ Processing Details: Restoration grinding of the mold surface *We are flexible in responding to inquiries like "Can you do this kind of processing?" Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding processes. With short delivery times and high quality as our strengths, we respond to our customers' needs. From small to large items, including cylindrical, flat, and internal grinding, you can trust us with everything from single-piece processing of iron to ceramics and carbide! We would like to introduce a case of our specialized grinding processing! This involved grinding a large workpiece exceeding 3 tons, which is unprecedented in our history. 【Grinding Processing Example】 ■ Size: Plate φ1450×640 ■ Material: Cast iron ■ Processing Details: Outer diameter, inner diameter, thickness (cylindrical, internal, flat grinding) ★ Key Points During Production: Our grinding machines can process up to φ1600×800 on vertical axis grinders. *We are flexible in responding to inquiries about processes that may seem challenging. Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding processes. With short lead times and high quality as our strengths, we respond to our customers' needs. From small to large items, including cylindrical, flat, and internal grinding, you can trust us with everything from single-piece processing of iron to ceramics and carbide! We would like to introduce a case of our specialized grinding processing! The "taper fitting processing" for large products is extremely challenging. 【Grinding Processing Example】 ■ Size: φ1500×230 ■ Product Name: Gear ■ Material: S45C ■ Processing Details: Inner diameter at φ360, 1/10 taper gauge fitting, step difference 0.010 ★ Key Points During Production: Despite being a large component, the 1/10 taper (with a cut of 0.005 resulting in a variation of 0.050) made it very difficult due to temperature changes and the strength required to insert the gauge, leading to significant variations in gauge insertion and extraction. *We are flexible in responding to inquiries like "Is this kind of processing possible...?" Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding (polishing) processes. With short delivery times and high quality as our strengths, we respond to our customers' requests. Whether it's small or large items, cylindrical, flat, or internal grinding, you can trust us with everything from single-item processing in iron to ceramics and carbide! We would like to introduce a case study of our grinding processing (multi-surface grinding)! This is an example of 13 chrome thermal spraying for large products. 【Grinding Processing Case Study】 ■ Size: φ1100×650 ■ Product Name: Large Manufacturing Line Component (Equipment Part) ■ Material: 13 Chrome Thermal Spray ■ Compatible Machine: Multi-surface Grinding Machine (Max φ1600×850) ■ Required Precision: 0.010 ★ Key Point During Production: We restored and polished the large manufacturing line component using 13 chrome thermal spray. *We are flexible in responding to inquiries like "Can you do this kind of processing...?" Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding processes. With short delivery times and high quality as our strengths, we respond to our customers' requests. From small to large items, including cylindrical, flat, and internal grinding, you can trust us with everything from single-piece processing of iron to ceramics and carbide! We would like to introduce a case study of our grinding processing (cylindrical grinding)! 【Grinding Processing Case Study】 ■Size: φ100×1200 ■Product Name: Crankshaft ■Required Precision: 0.010 ★Key Points During Production: Although we do not use a crank grinding machine, we can accommodate shaft grinding by placing centers in two locations. Additionally, with the center holes, three eccentricities and four eccentricities are also possible. *We are flexible in responding to inquiries about what kind of processing can be done. Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding processes. With short delivery times and high quality as our strengths, we respond to our customers' requests. From small to large items, including cylindrical, flat, and internal grinding, you can trust us with everything from single-piece processing of iron to ceramics and carbide! We would like to introduce a case study of our grinding processing (flat grinding)! This is a case handled by a specialized grinding machine that excels in grinding ring shapes. 【Grinding Processing Case Study】 ■ Size: φ700×20 ■ Product Name: Circular Table ■ Material: SS400 ■ Processing Equipment: Horizontal Axis Rotary Grinding Machine (max φ820×250) ■ Required Precision: Flatness 0.010 ★ Key Point During Production: We handled this with a grinding machine that specializes in flat grinding of ring shapes. *We are flexible in responding to inquiries like "Can you do this kind of processing...?" Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding (abrasive) processes. With short lead times and high quality as our strengths, we respond to our customers' needs. From small to large items, including cylindrical, flat, and internal grinding, you can trust us with everything from single-piece processing of iron to ceramics and carbide! We would like to introduce a case study of our grinding processing (cylindrical grinding)! We restored the precision of items that had deteriorated due to wear through methods such as thermal spraying and plating. 【Grinding Processing Case Study】 ■ Size: φ300×3500 ■ Product Name: Carbide Thermal Spray Roll Grinding (Line Equipment Parts) ■ Material: Carbide Thermal Spray (Base Material: Iron) ★ Key Points During Production: We restore the precision of items that have deteriorated due to wear during use through thermal spraying or plating. *We are flexible in responding to inquiries about whether such processing can be done. Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding (abrasive) processes. With short lead times and high quality as our strengths, we respond to our customers' requests. Whether it's small or large items, cylindrical, flat, or internal grinding, you can trust us with everything from single-piece processing of iron to ceramics and carbide! We would like to introduce a case study of our grinding processing (flat grinding)! 【Grinding Processing Case Study】 ■ Size: 900×600×120 ■ Product Name: V Flat Slide Table (Machine Tool Component) ■ Material: Cast Iron ★ Key Points During Production: Since it serves as the sliding surface of machine tools, high precision and cleanliness of the processed surface are required. By using movable vertical axis grinding or grinding wheel shaping, we can achieve high precision taper angles and undercut grinding. *We are flexible in responding to inquiries like "Can you do this kind of processing...?" Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

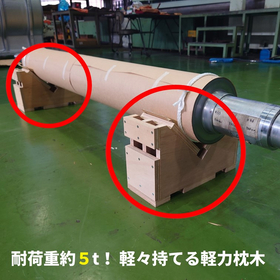

We sell "sleepers" measuring 400×250×150mm. The reference load capacity is 6 tons per unit when using a φ210 workpiece, which is the damage level. Weighing 3 kg, it can be easily held with one hand, even by women, and is convenient for truck transportation. We have developed the sleepers that we have wanted for many years based on our experience. Please feel free to contact us when you need them. 【Features】 ■ 400×250×150mm ■ Easy to hold with one hand, even by women ■ Load capacity of approximately 5 tons ■ Convenient for truck transportation *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding (polishing) processes. With short delivery times and high quality as our strengths, we respond to our customers' needs. Whether it's small or large items, cylindrical, flat, or internal grinding, you can trust us with everything from single-item processing of iron to ceramics and carbide! Here we introduce a case study of our grinding processing (outer diameter + inner diameter grinding). Amano Grinding Industry is committed to achieving single-item processing with short delivery times and high quality! 【Grinding Processing Case Study】 ■ Size: φ200×1300 ■ Product Name: Long Spindle ■ Material: SUS4 series ■ Required Processing Precision: 0.010 or less ■ Processing Steps: Outer diameter and inner diameter grinding ★ Key Points During Production: The photo shows the processing of a hole with a diameter of φ150 and a depth of 220 on a grinding machine with a maximum capacity of φ1000×2000. The size of the workpiece and hole depth are subject to consultation. * We are flexible in responding to inquiries about processing that may seem challenging. Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding (abrasive) processes. With short delivery times and high quality as our strengths, we respond to our customers' requests. From small to large items, including cylindrical, flat, and internal grinding, you can trust us with everything from single-piece processing of iron to ceramics and carbide! We would like to introduce a case study of our grinding processing (cylindrical grinding)! This is a very large product with a total length of 4400, known as a hearth roll used in steel mills. 【Grinding Processing Case Study】 ■ Size: φ800×Body Length 2050×Total Length 4400 ■ Product Name: Hearth Roll (Steel Mill Related Component) ■ Processing Method: Taper crown grinding using a large cylindrical grinding machine (maximum φ1100×7000) ★ Key Points during Production: For cylindrical grinding, we can accommodate up to [maximum φ1100×7000], allowing us to flexibly handle large products. *We are flexible in responding to inquiries such as "Can you do this kind of processing...?" Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding (abrasive) processes. With short lead times and high quality as our strengths, we respond to our customers' needs. From small to large items, including cylindrical, flat, and internal grinding, you can trust us with everything from single-piece processing of iron to ceramics and cemented carbide! We would like to introduce a case of our grinding processing (cylindrical grinding)! This example includes grinding processes for large products as well as plating treatment. *For cylindrical grinding, we can accommodate up to [maximum φ1100×7000]! 【Grinding Processing Example】 ■ Size: φ1100×1950 ■ Product Name: Piston ■ Material: Hard Chrome Plating (Base Material: Iron) ■ Processing Steps: Grinding before and after plating using a large cylindrical grinding machine (maximum φ1100×7000) ★ Key Points During Production: We are open to consultations not only for grinding processes but also for other processes such as plating and hardening. *We are flexible in responding to inquiries like "Can you do this kind of processing...?" Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding (polishing) processes. With short delivery times and high quality as our strengths, we respond to our customers' needs. Whether it's small or large items, cylindrical, flat, or internal grinding, you can trust us with everything from single-piece processing of iron to ceramics and carbide! We would like to introduce a case of our grinding processing (multi-surface grinding)! This involves internal diameter grinding for large products. 【Grinding Processing Case】 ■ Size: φ1460×135, Internal diameter φ1400 ■ Product Name: Carbide Thermal Spray Ring ■ Material: Carbide thermal spray (base material: iron) ■ Processing Steps: Internal diameter grinding of large parts using a multi-surface grinding machine after thermal spraying the internal diameter with carbide ■ Precision: Roundness of 0.01 or less ★ Key Points During Production: Our multi-surface grinding machine can process internal diameters, external diameters, and end faces up to a maximum of φ1600×800. We have grinding wheels available for various materials, not just iron, but also carbide, ceramics, and more. *We are flexible in responding to inquiries like "Can you do this kind of processing...?" Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Amano Grinding Industry, we are a team of experts specializing in various grinding processes. With short delivery times and high quality as our strengths, we respond to our customers' needs. From small to large items, including cylindrical, flat, and internal grinding, you can trust us with everything from single-piece processing of iron to ceramics and carbide! We would like to introduce a case study of our grinding processing (flat grinding)! It is a very special product. 【Grinding Processing Case Study】 ■ Size: 1300×290 mm (octagonal prism) ■ Product Name: Ram (machine tool component) ■ Material: Cast iron ■ Processing Method: Taper flat grinding with a grinding wheel diameter of φ355 and a large turning axis ■ Precision: Flatness and parallelism within 0.01 mm ★ Key Point during Production: A clean machined surface was required as it is a sliding part visible outside the machine tool. *We are flexible in responding to inquiries like "Can you do this kind of processing...?" Please feel free to consult with us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Processing Examples】 General shafts, spindles, equipment rolls, jigs and tools, prototypes, other general machine parts, regrinding of used parts, etc. 【Material Examples】 General iron, carbide, ceramics, aluminum, Teflon, and others upon consultation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Processing Examples】 General plates, general rails, motor cores, molds, machine tool slides, jigs and fixtures Prototypes, general machine parts, regrinding of used parts, etc. 【Material Examples】 General iron, carbide, ceramics, aluminum, Teflon, and others upon consultation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Processing Examples】 Spindles, jigs and tools, prototypes, general machine parts, regrinding of used parts, etc. 【Material Examples】 General iron, carbide, ceramics, aluminum, Teflon, and others upon consultation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Processing Examples】 Discs, ring shapes, jigs, general machine parts, regrinding of used parts 【Material Examples】 General iron, carbide, ceramics, aluminum, Teflon, and others upon consultation

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We conduct route sales in Aichi, Gifu, Mie, and Shizuoka (area consultation required) using 3t to 4t trucks. Please feel free to inquire about not only grinding processing but also other types of processing.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration