1~39 item / All 39 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~39 item / All 39 items

Filter by category

Towa Manufacturing Co., Ltd. conducts all processes from core processing, rubber mixing, molding to polishing in a consistent production manner, and provides sales and service support. Due to in-house consistent production, we can quickly respond by confirming and adjusting each process. We can accommodate various requests, including core processing only, processing with supplied materials, and rubber rewrapping. If you have any projects where we can be of assistance, we would appreciate it if you could let us know. 【Strengths】 ■ Flexible response through in-house consistent production ■ Products handled through collaboration with partner companies *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Fabric Seal" that we handle. With water-absorbent swelling fibers and a seamless structure, it enables easy water stopping and sealing. The material is safe as it is used in construction and civil engineering. In addition, we offer fabric seal materials for powder that can be selected in natural or synthetic materials according to the application, as well as heat-resistant seal materials made from ultra-fine metal fibers. 【Product Lineup】 ■ Water Stopping ■ Powder Use ■ High-Temperature Heat Resistance *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Liquid Jet Series" consists of two models of upward automatic liquid dispensing devices that can be chosen according to the usage scene. The "LJ-01," which has a long battery life and can be used by more people, and the "LJ-02," which has become more accessible in a palm-sized design, are both available. We also offer a variety of options to meet diverse needs. [Color and Option Versions] ■LJ-01: Color lineup - Silver, White, Blue, Pink, Black ■LJ-02: Battery option (24H compatible) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Special Transport Belt" is a jointly developed product that combines innovative ideas and technology. It can ensure uniform breathability without creating holes. It excels in bend resistance, allowing for miniaturization of devices and providing grip on necessary surfaces. 【Features】 ■ Ensures uniform breathability without creating holes ■ Low air resistance enables miniaturization of suction mechanisms ■ Strong against fraying and has a long lifespan (fraying prevention technology) ■ Excellent bend resistance allows for device miniaturization ■ The belt is lightweight and can be driven with low torque *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Special Roller Series." We offer products such as the "Coated Mesh Roller," which achieves excellent release properties with a special mesh, and the "Lightweight Elastic Roller," which does not use rubber or sponge. We also have the "Coated Stripe Step Roller," which realizes stable high cleaning performance. Please feel free to consult us when you need assistance. 【Coated Mesh Roller Features】 ■ Small contact area for excellent release properties ■ Adhesive materials (such as double-sided tape) are less likely to stick ■ The use of monofilament with a circular cross-section makes the surface less prone to dirt ■ The thickness step structure of the mesh minimizes clogging ■ Various materials and thicknesses can be selected according to specifications *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Polyurethane rubber is a type of plastic that can be simply described as "plastic with rubber-like elasticity." The polyurethane rubber we handle comes in two types: "Mirable Polyurethane" and "Liquid Polyurethane." "Mirable Polyurethane" is a product made from solid materials that are the same as common rubber materials. "Liquid Polyurethane" is, as the name suggests, a product made from liquid raw materials. 【Features】 ■ Advantages - High wear resistance and mechanical strength - Oil resistance (ester-based) ■ Disadvantages - Heat resistance, water resistance (ester-based) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts all processes from the core processing of rubber rollers to rubber mixing, molding, and polishing, providing integrated production, sales, and services for rubber rollers. Here is a list of the physical properties of rubber. The aging properties section contains actual measured values from aging tests. *Please note that these are measured values and do not guarantee performance. [Excerpt of Physical Properties] ■ Liquid urethane ether type - natural color ■ Liquid urethane ester type - natural color ■ EDPM - black ■ EDPM - gray *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

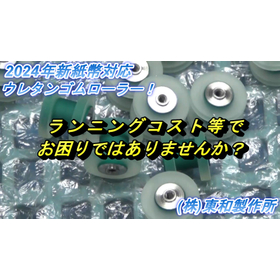

Our company specializes in the manufacturing of high-quality "liquid urethane rubber rollers." We have maintained a long-term relationship with financial terminal manufacturers, and our products have been selected for use in terminals compatible with the new banknotes. Our products are also adopted in many overseas products and have received high praise for their quality. This praise is largely due to their low incidence of problems and favorable running costs. The reason for this is that we conduct consistent production from core processing to rubber molding, and we possess the know-how for mold design that takes into account the precision of core processing based on the drawings provided by our customers! 【Features】 ■ High strength and excellent wear resistance ■ Capable of accommodating various hardness levels through formulation ■ Options for ether-based and ester-based materials ■ Thorough quality control during manufacturing *Please feel free to contact us with any questions about our products or rubber, even if they are simple inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■ Improvement Proposal - Make the rubber softer. - Change the thickness of the rubber. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■Causes of Problems - Defective core - Defective rubber, etc. In general, the manufacturing of rubber rollers often involves supplied or purchased cores, which makes it difficult to investigate issues in detail when problems arise. It can be hard to quickly determine whether the issue is with the core or the rubber, leading to unexpected costs and time delays. ▼Improvement Measures Our company offers integrated in-house production from core selection to rubber selection. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Solving your rubber roller problems. Introducing examples of improved replacement frequency! 【Situation/Challenge】 Company D was experiencing severe wear on the feed rollers of their printing machines and desired better durability, while also being concerned about transfer marks caused by slippage. 【Improvement Measures】 We proposed our previously developed 'wear-resistant EPDM'. They conducted prototype evaluations. 【Results】 As a result, they expanded the positive feedback from the new model to existing models, and it is now widely used. 【Case Overview】 ■ Background: Upgrading the feed transport roller section ■ Solution: Using rubber material developed by our company ■ Effect: Adoption not only in new models but also in existing models *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Rubber rollers are commonly used in industrial equipment, but not much is known about the types of equipment used to manufacture them. Therefore, we would like to introduce some of our facilities. At our company, we change our equipment according to the type of rubber and are also capable of metal processing, allowing us to create high-precision products through core processing calculated from the completed design of the rubber rollers. In particular, liquid urethane has received high praise from our clients. 【Equipment Owned】 ■ 15 Automatic Lathes ■ 2 Milling Machines ■ 3 Broaching Machines ■ 18 Bench Lathes ■ 29 General-purpose Grinding Machines ■ 20 Automatic Grinding Machines ■ 1 CNC Grinding Machine *In addition to the equipment we own, we are distributing materials that introduce our quality control. Please check it from "Download."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company carries out all processes from core processing of rubber rollers to rubber mixing, molding, and polishing, featuring a consistent production of rubber rollers. We would like to discuss the challenges and solutions regarding stabilization during the adhesion of rubber to shafts. [Challenges] - Shafts processed on a lathe have rough surface marks similar to those on a record. - Additionally, heat-treated shafts have hard surfaces that are difficult to polish. - If polishing is insufficient, only the surface is polished, leaving the grooves of the rough marks unpolished. [Solutions] → Improve the polishing method and pre-treatment of the shafts. For more details, please download the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Duplo Seiko Co., Ltd. develops cutting machines and printing machines tailored to customer needs, both domestically and internationally, from Wakayama Prefecture, and among these, parts made by Towa are actively utilized. The company was experiencing significant wear on the feed rollers of their printing machines and desired greater durability, while also being concerned about back transfer due to slip marks. In response, we proposed our previously developed "wear-resistant EPDM." They conducted prototype evaluations. As a result, they received positive feedback on the new model, leading to its broader application and adoption in existing models, where it is now widely used. [Case Overview] ■ Background: Upgrading the feed transport roller section ■ Solution: Use of rubber material developed by our company ■ Effect: Adoption not only in new models but also in existing models *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our products: "Hydraulic and Pneumatic Valve Bodies / Fastener Seals / Squeeze Blades." The "Hydraulic and Pneumatic Valve Bodies" are components used in industrial robots, supporting the precise operation of hydraulic and pneumatic equipment by polishing rubber diameters and R shapes to a level of 0.01mm. The "Fastener Seals" are lined with sealing material on the inner surface, used to prevent internal leaks and intrusion of foreign objects. The "Squeeze Blades" can achieve a thickness precision of ±0.03, enabling high-precision molding and ensuring reliable scraping. 【Features】 ■ Hydraulic and Pneumatic Valve Bodies - Supports the precise operation of hydraulic and pneumatic equipment - Products for sealing, cushioning, and packing applications are also available ■ Fastener Seals - Lined with sealing material on the inner surface - Used to prevent internal leaks and intrusion of foreign objects *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Flat Grinding Products (Flat Grinding Machines)." The "Flat Platens" used in passbook printers and other devices are made by bonding high-hardness rubber, forming a highly precise flat surface. The "Rotating Plate (Coin Counting Machine)" improves thickness "variability" by applying urethane rubber to the metal sheet and then performing flat grinding. 【Features】 ■ Flat Platens - Used in passbook printers and other devices - Form a highly precise flat surface by bonding high-hardness rubber ■ Rotating Plate (Coin Counting Machine) - Improves thickness "variability" by applying urethane rubber to the metal sheet and then performing flat grinding *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Long Roller." We can handle the molding of rubber rollers exceeding 1 meter in length and external diameter grinding. At Towa Seisakusho, we carry out all processes from core processing of rubber rollers to rubber mixing, molding, and grinding, enabling us to provide integrated production and sales of rubber rollers. Please feel free to contact us when you need assistance. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Large Diameter Roller <Drum for High-Speed Printing Machines>." We have resolved issues such as negative opening dimensions and bouncing that are common in parts with irregular shapes through our polishing technology. At Towa Seisakusho, we carry out the entire process from core processing of rubber rollers to rubber mixing, molding, and polishing, enabling us to provide consistent production and sales of rubber rollers. Please feel free to contact us when you need assistance. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Wear-Resistant EPDM Products." Since no carbon is used in the reinforcing material, there are no issues with slip marks, and it can be installed in multifunction printers' ADFs and paper feed units. It offers wear resistance and weather resistance, contributing to a reduction in lifecycle costs due to its long lifespan. 【Features】 ■ No issues with slip marks as no carbon is used in the reinforcing material ■ Can be installed in multifunction printers' ADFs and paper feed units ■ Contributes to a reduction in lifecycle costs due to wear resistance, weather resistance, and extended lifespan ■ Compatible hardness: JIS A30 to 45° *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "pulleys for equipment transportation." We offer pulleys with pressed ball bearings for production system equipment transportation such as FA (Factory Automation), as well as small assemblies. Additionally, we also provide repair services for deteriorated rubber (rubber rewrapping and hardware reuse), so please feel free to contact us. 【Features】 ■ Pulleys with pressed ball bearings for production system equipment transportation such as FA, as well as small assemblies ■ Repair services for deteriorated rubber (rubber rewrapping and hardware reuse) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts "small assembly/unit production." We perform small assemblies of core materials, rubber, resin, bearings, sheet metal, etc., in-house and supply them. This contributes to reducing our customers' management workload (quality, cost, ordering, inventory, etc.). In addition to small assemblies, we also accept unit production, so please feel free to let us know your needs. 【Features】 ■ Supply of small assemblies of core materials, rubber, resin, bearings, sheet metal, etc. ■ Contribution to reducing our customers' management workload (quality, cost, ordering, inventory, etc.) ■ Support for both small assemblies and unit production *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "High Hardness Shafts / Fine Knurling Products." The "High Hardness Shaft" can accommodate mechanisms that require high hardness by applying heat treatment to iron and stainless steel materials. The "Fine Knurling Products" feature a self-cleaning function to address dirt issues in color images, forming fine protrusions on the surface. This contributes to reducing life cycle costs. 【Features of High Hardness Shafts】 ■ By applying heat treatment to iron and stainless steel materials, it can accommodate mechanisms that require high hardness (approximately HV850). ■ Depending on the application, we can also propose high hardness materials that are not heat-treated (HV400-500). ■ Significantly contributes to reducing component costs. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Grooved Products (NC Grinding Machine)." By building programs on the NC grinding machine, various groove processing is possible. We have a track record of parts with a required specification of rubber position tolerance ±0.075mm, as well as for banknote and coin identification. 【Features】 ■ Various groove processing is possible by building programs on the NC grinding machine ■ Track record of parts with a required specification of rubber position tolerance ±0.075mm ■ Proven results for banknote and coin identification *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "Molded Products / Irregular Press-Fit Products" that we handle. "Molded Products" can provide various shapes, including wing shapes, gear shapes, hollow shapes, and plate shapes. "Irregular Press-Fit Products" enable uniform paper alignment by forming phases for each wing during the press-fitting process. The precision of each angle is crucial, and these parts are established through press-fitting know-how. 【Features】 ■ Molded Products - Can provide products in various shapes ■ Irregular Press-Fit Products - Enables uniform paper alignment by forming phases for each wing during the press-fitting process - The precision of each angle is crucial, and these parts are established through press-fitting know-how *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "various coating parts" that we handle. Starting with "urethane-coated products," which achieve high friction (high μ) by coating a base of NBR with a urethane film, we also offer "ceramic processed products" suitable for paper, film, and repeated movement. Please feel free to contact us when you need assistance. 【Features】 ■ Urethane Coated Products - Achieves high friction (high μ) by coating a base of NBR with a urethane film - Improves transport performance through reliable grip - The base material is not limited to NBR ■ Ceramic Processed Products - Suitable for paper, film, and repeated movement - Offers good feeding accuracy and improves printing misalignment accuracy *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "general cutting parts and metal, aluminum, and resin rollers" that we handle. In-house processing is available for outer diameters up to φ32, but anything larger can be processed by our partner companies. We also accommodate Mitsuya pipes and other pipe processing. Additionally, depending on the size of the processing lot, overseas procurement is possible, and we can also handle various metal single items and products made of metal and resin. Please feel free to contact us when you need our services. 【Features】 ■ In-house processing range: φ4 to φ32 ■ Available materials: SUS, SUM, AL, BSBM (brass), SK, etc. ■ Accommodates Mitsuya pipes and other pipe processing ■ Can also handle various metal single items and products made of metal and resin ■ Overseas procurement is possible depending on the content *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts "rim molding." "Silicone rubber" has a minimum thickness of 500μm and a rubber hardness of 1 to 40 JIS A. "PFA tubes" are available in types without creases and relaxation types. At Towa Seisakusho, we carry out all processes from core processing of rubber rollers to rubber mixing, molding, and polishing, enabling us to provide integrated production and sales of rubber rollers. Please feel free to contact us when you need our services. 【Silicone Rubber】 ■ Minimum thickness [μm]: 500 ■ Thermal conductivity [W/m·K]: 0.2 to 0.6 ■ Rubber hardness [JIS A]: 1 to 40 ■ Conductive type (Ω): E+05 to E+07 *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the products we handle: "Die-cut processed products / Sponge rollers / Metal press parts." "Sponge rollers" are used for the transportation of thin films and similar materials. "Metal press parts" contribute to reducing initial costs by manufacturing only the variable parts using cassette molds. Large housings will be considered separately. Please feel free to contact us when you need assistance. 【Features】 ■ Die-cut processed products - Die-cut (Mylar and rubber sheet) processed products ■ Sponge rollers - Used for the transportation of thin films and similar materials ■ Metal press parts - Contributes to reducing initial costs by manufacturing only the variable parts using cassette molds *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the products we handle: "Gears and Pulleys / Mechanical Components and Assemblies / Control Knobs / Cassette Molds." By using cassette molds, we contribute to reducing initial costs by manufacturing only the variable parts. At Towa Seisakusho, we carry out all processes from core processing of rubber rollers to rubber mixing, molding, and polishing, enabling us to provide integrated production and sales of rubber rollers. Please feel free to contact us when you need our services. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Urethane Bearing Roller." This product features urethane directly bonded to bearings and one-way clutches, manufactured in a way that does not affect the bearings. The outer diameter is finished with polishing. Generally, it is used in various applications such as financial terminals, ticket vending machines, transport machinery, medical devices, food machinery, packaging machinery, and health equipment. There are no standard dimensional restrictions for the bearings used. 【Features】 ■ Urethane directly bonded to bearings and one-way clutches ■ Manufactured in a way that does not affect the bearings ■ Outer diameter finished with polishing ■ No standard dimensional restrictions for the bearings used *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Towa Manufacturing Co., Ltd., we handle "Conveyor Rollers / Platen Rollers." "Conveyor Rollers" can be processed in various shapes and specifications. Silicone rubber and urethane rubber are available in a Mirable type. Additionally, "Platen Rollers" are products designed for serial dot printers. The materials used are mainly SBR and NBR with a hardness of JIS C85° to 100°. 【Features】 <Conveyor Rollers> ■ Used in various applications and fields ■ Can be processed in various shapes and specifications *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Towa Manufacturing Co., Ltd., we handle "large diameter rollers." We offer solutions to issues such as negative opening dimensions and easy bouncing in parts with irregular shapes, starting with the "drum for high-speed printers," which resolves these concerns through our polishing technology, as well as the "large diameter platen roller" for L-size photo printers. 【Product Lineup】 ■ Drum for high-speed printers ■ Large diameter platen roller (for L-size photo printers) *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Towa Manufacturing Co., Ltd., we handle "high-precision conveyor rollers." These products are used in the conveying section of double-sided printers, where print misalignment is a concern, and they provide high-precision paper feeding and belt feeding, resulting in significantly different outer diameter runout precision compared to standard conveyor rollers. In addition to the ribbed tube type shown in the photo, shaft type processing is also possible. 【Runout Precision】 ■ A4 Type: 10μm or less ■ A3 Type: 15μm or less *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product is a rubber roller commonly used in financial terminals. The urethane we handle is made with a high-strength grade, offering excellent wear resistance, and our formulation allows for various hardness levels. Additionally, this product is available in two types: ether and ester. Please contact us for more details. 【Features】 ■ Widely used in financial terminals ■ Raw materials are classified into ether-based and ester-based materials *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product is a roller that achieves high hardness and high μ by being made in two layers. It allows for a flexible configuration in terms of required characteristics. Compared to using sponge in the inner layer, it also excels in resilience. Additionally, we have experience with rubber materials such as EPDM and liquid urethane. For more details, please contact us. 【Features】 ■ Hard rubber used for the outer layer ■ Achieves high hardness and high μ by being made in two layers ■ Allows for a flexible configuration in terms of required characteristics ■ Proven performance with rubber materials such as EPDM and liquid urethane *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "TS-50 type" is a sound-absorbing rubber for anechoic water tanks that has good sound absorption rates even at low frequencies compared to wooden sound-absorbing wedges, and it allows for stable measurements over a long period due to minimal water quality contamination. Since it does not use wood and does not rot, maintenance and upkeep of the tank are easy. It also contributes to environmental protection. Additionally, the facility costs are lower compared to those using wood. 【Features】 ■ Good sound absorption characteristics even at low frequencies (5kHz) ■ Stable sound absorption characteristics under pressure (4kg/cm²) ■ Minimal changes over time, allowing for stable measurements ■ Minimal water quality contamination, making maintenance and upkeep of the tank easy ■ Does not use wood, contributing to environmental protection ■ Facility costs are lower compared to those using wood *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts all processes from core processing of rubber rollers to rubber mixing, molding, and grinding, providing integrated production, sales, and services for rubber rollers. With a variety of formulations and methods, and through collaboration with partner companies, we can optimize our offerings to meet customer requests and requirements. Since we manufacture the cores in-house, we can respond flexibly to fluctuations in volume. 【Business Activities】 ■ Production and sales of rubber rollers ■ Prototype development and processing technology for rubber rollers We offer a wide range of products, including "heat rollers (thin type)," "adhesive rollers," and "high-precision transport rollers." *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is often used in rollers for financial terminals. The raw materials are classified into ether-based and ester-based materials. Ether-based liquid urethane rubber has excellent abrasion resistance and hydrolysis resistance, available in high-strength grades (hardness A70 to 95°) and low-hardness grades (hardness A50 to 70°). Ester-based liquid urethane rubber has excellent abrasion resistance, ink resistance, and chemical resistance, available in high-strength grades (hardness A70 to 95°) and low-hardness grades (hardness A50 to 70°). *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Used in the transport section of duplex printers where print misalignment is an issue, it performs high-precision paper feeding and belt feeding, resulting in a significantly different product stability accuracy compared to standard transport rubber rollers. In addition to the ribbed tube type shown in the photo, solid shaft type processing is also possible. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration