- Publication year : 2025

1~5 item / All 5 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~5 item / All 5 items

Due to popular demand for the VMQE soft rubber processing end mills, we have added φ3 and φ4 to our lineup. We will be showcasing them at the Sanyo Tool Co., Ltd. booth and the Yamakatsu Shokai booth at MECT2025, so please come and visit us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

10 years since its release in 2015! We would like to reintroduce the product "BL-HFD/BL-OHFD," which continues to receive high praise from many customers! BL-HFD (without oil hole) / BL-OHFD (with oil hole) Ultra-hard drill for aluminum with BURR LESS design The "BL series" is a high-precision, high-efficiency ultra-hard drill that adopts a blade shape that significantly suppresses burr generation, as the name "BURR LESS" suggests. Especially with A5052 material, it reduces burr height to less than 1/10 of the conventional level and achieves hole diameter accuracy at H7 level, enabling high-quality hole processing. Product Features: • BL-HFD: Simple blade shape for easy regrinding and excellent cutting performance reproducibility • BL-OHFD: Improved processing stability with internal lubrication support • Dimension Variations: φ2.5 to φ12 (0.1mm steps) Furthermore, with DLC coating support, it can universally handle a wide range of aluminum materials, including aluminum extrusions. Expect improvements in wear resistance, extended tool life, and enhanced surface quality of the processed holes. It balances the reduction of post-processing man-hours in aluminum machining with high precision and high-quality hole drilling. This drill brings innovation to all sites involved in aluminum hole drilling.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thank you for your patience! We had been holding off on the announcement for the patent application, but we are pleased to inform you that we have officially completed the patent application. *This is a jointly developed product with Uchiyama Knife Co., Ltd.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Tool used: TC-D20・ST-TC-D20 (staggered blade) Groove width: 3mm Depth: 3mm (one-pass processing with upper cut) Can also be used on materials other than metal. If processed at high speed with low feed, both TC and ST-TC will finish beautifully.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

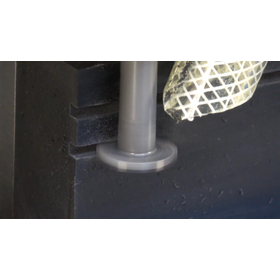

This time, I tried using the new product [NCFC] New Chamfering Cutter to perform chamfering on natural rubber (black rubber) with a hardness of 60. I believe that the angle of the cutting edge in the rotational direction improves machinability, allowing it to be used on a variety of workpieces.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration