- Publication year : 2023

1~45 item / All 149 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~45 item / All 149 items

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, are realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

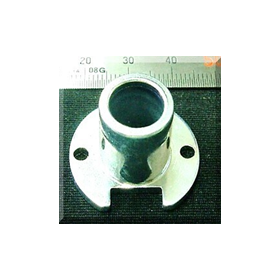

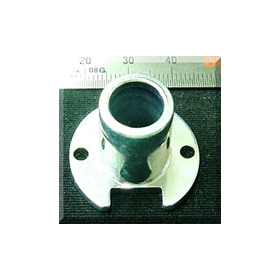

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing process) under optimal conditions. 【Features】 - Uniform processing of product thickness - All flange and drawing areas have a uniform thickness - Material: SPCE t2.0mm - Significant cost reduction in material and processing costs compared to machined products - Used for automotive components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using processing methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing process) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All flange and drawing areas have uniform thickness ■ Material: SPCE t2.0mm ■ Achieved significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using processing methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet cold forging + drawing processing) under optimal conditions. 【Features】 - Uniform processing of product thickness - All flange and drawing areas have uniform thickness - Material: SPCE t2.0mm - Achieved significant cost reduction in material and processing costs compared to cutting products - Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using processing methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing process) under optimal conditions. 【Features】 - Uniform processing of product thickness - All flange and drawing areas have a uniform thickness - Material: SPCE t2.0mm - Achieved significant cost reduction in material and processing costs compared to cutting products - Used for automotive components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using processing methods such as cutting and pipe processing, can be achieved through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All flange and drawing areas have uniform thickness ■ Material: SPCE t2.0mm ■ Achieved significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. The flow of material within the mold can be freely controlled, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All flange and drawing areas have uniform thickness ■ Material: SPCE t2.0mm ■ Achieved significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical parts ■ Fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical parts ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

<Broadcast Date and Time Information> TV Station: Gunma TV Program Name: Business Journal Broadcast Date and Time: July 14, 2023 (Friday) 22:00 - 22:30 (Rebroadcast) - July 16, 2023 (Sunday) 7:30 - 8:00 (Re-rebroadcast) - July 18, 2023 (Tuesday) 19:00 - 19:30 *Please note that the broadcasted program will be available for viewing on the Gunma Bank website for two months in October and November 2023.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing processing) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All plate thicknesses in the flange and drawing sections are finished uniformly ■ Material: SPCE t2.0mm ■ Achieved significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All flange and drawing areas have uniform thickness ■ Material: SPCE t2.0mm ■ Significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing process) under optimal conditions. 【Features】 - Uniform processing of product thickness - All flange and drawing areas have uniform thickness - Material: SPCE t2.0mm - Significant cost reduction in material and processing costs compared to cutting products - Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using processing methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 - Uniform processing of product thickness - All flange and drawing areas have uniform thickness - Material: SPCE t2.0mm - Significant cost reduction in material and processing costs compared to cutting products - Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All plate thicknesses in the flange and drawing sections are finished uniformly ■ Material: SPCE t2.0mm ■ Achieved significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical parts ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All plate thicknesses in the flange and drawing areas are finished uniformly ■ Material: SPCE t2.0mm ■ Achieved significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using processing methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 - Uniform processing of product thickness - Uniform finishing of all plate thicknesses in the flange and drawing sections - Material: SPCE t2.0mm - Significant cost reduction in material and processing costs compared to machined products - Used for automotive components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing process) under optimal conditions. 【Features】 - Uniform processing of product thickness - All plate thicknesses in the flange and drawing sections are finished uniformly - Material: SPCE t2.0mm - Significant cost reduction in material and processing costs compared to cutting products - Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as advanced technology in the medical industry, enabling fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical parts ■ Fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. The flow of material within the mold can be freely controlled, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All plate thicknesses in the flange and drawing sections are finished uniformly ■ Material: SPCE t2.0mm ■ Achieved significant cost reductions in material and processing costs compared to cutting products ■ Used for automotive components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing process) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ Uniform finishing of all plate thicknesses in the flange and drawing areas ■ Material: SPCE t2.0mm ■ Significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be achieved through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical parts ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. The flow of material within the mold can be freely controlled, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 - Uniform processing of product thickness - All flange and drawing areas have uniform thickness - Material: SPCE t2.0mm - Significant cost reduction in material and processing costs compared to cutting products - Used for automotive components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be achieved through fine deep drawing processing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as an advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. The flow of material within the mold can be freely controlled, successfully realizing the FCF method (sheet metal cold forging + drawing processing) under optimal conditions. 【Features】 - Uniform processing of product thickness - All plate thicknesses in the flange and drawing sections are finished uniformly - Material: SPCE t2.0mm - Significant cost reduction in material and processing costs compared to cutting products - Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. The flow of material within the mold can be freely controlled, successfully realizing the FCF method (sheet metal cold forging + drawing process) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All flange and drawing areas have a uniform thickness ■ Material: SPCE t2.0mm ■ Significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel ■ Adopted as advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It is possible to freely control the flow of material within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All flange and drawing areas have a uniform thickness ■ Material: SPCE t2.0mm ■ Achieved significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thin-walled tapered and multi-stage shaped products, which are considered difficult to manufacture using machining methods such as cutting and pipe processing, can be realized through fine deep drawing technology. This technology is adopted as an advanced technology in the medical industry, enabling fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03. 【Features】 ■ Realization of ultra-fine medical components ■ Fine deep drawing processing with an outer diameter of φ0.4mm and a wall thickness of 0.03 ■ Ultra-fine deep drawing using stainless steel materials ■ Adopted as advanced technology in the medical industry

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By utilizing a servo press machine, the stroke speed can be adjusted in several stages. It allows for precise control of the material flow within the mold, successfully realizing the FCF method (sheet metal cold forging + drawing) under optimal conditions. 【Features】 ■ Uniform processing of product thickness ■ All plate thicknesses in the flange and drawing sections are finished uniformly ■ Material: SPCE t2.0mm ■ Achieves significant cost reduction in material and processing costs compared to cutting products ■ Used for automotive components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration