1~16 item / All 16 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~16 item / All 16 items

Even metals referred to as "alloys" have diverse characteristics such as rigidity and toughness depending on their components. In order to achieve a higher level of the total balance of required functions, precision, and durability, we select suitable materials, challenge conventional wisdom, and pursue ideas that go beyond it. Here, the experience and sensitivity of the technicians who perform the processing are fully demonstrated. Our company can achieve ultra-mirror finishing through our unique lapping technology. If you are struggling with balancing surface properties and dimensional tolerances, please contact us. 【Features】 ■ Selection of suitable materials to achieve a higher level of the total balance of required functions, precision, and durability ■ Challenging attempts based on ideas that go beyond conventional wisdom *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is not an exaggeration to say that the precision of each component that makes up the machine speaks to the overall reliability. Currently, micron-level precision is required for key components and jigs among them. In addition to the production of plug gauges, ring gauges, calipers, height gauges, taper gauges, special gauges, various gauges, and jigs, we also handle design and manufacturing. To fulfill the function of a gauge, we pay close attention to dimensional accuracy, temperature changes, distortion, scratches, cracks, and other factors during processing. [Features] ■ Demonstrates capabilities in the micron realm ■ Processes with meticulous attention to dimensional accuracy, temperature changes, distortion, scratches, cracks, etc. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures ultra-precision parts that achieve the required accuracy. In the case of mechanical parts, even a deviation of 1 micron can lead to millimeter-level discrepancies depending on the environment and usage conditions. Understanding the importance of precision, we prioritize being satisfied with our work and being able to deliver with confidence and pride. This can be seen as a commitment of engineers that is akin to that of a ceramic artist. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We are constantly demonstrating our technical expertise to provide reliable quality in areas that are not always visible. We take on the challenge of producing prototypes and precision machining according to requirements. We carefully listen to our customers' ideas and thoughts, delivering products tailored to their needs in terms of quality, cost, and delivery time. [Features] ■ Carefully listening to our customers' ideas and thoughts ■ Delivering products tailored to needs in terms of quality, cost, and delivery time ■ Providing "the precision required for further quality" *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Please leave the assembly of precision parts to Komori Seiki. As the demand for higher precision and quality continues to grow, we have been able to provide the required precision with our technical capabilities when our customers encounter technical barriers. This repetition has built trust, and our technical expertise is recognized not only domestically but also widely overseas. We are aiming to expand our activities into a broader field to contribute to the qualitative improvement of the entire industrial sector. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

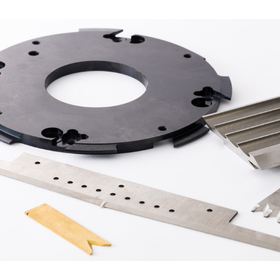

Since our establishment, we have been responding to a variety of materials such as high-speed steel, powdered high-speed steel, and die steel, based on the experience and achievements gained from manufacturing cutting tools. By shaping and grinding grinding wheels, we can produce cutting tools in a wide variety of shapes. Without being constrained by preconceived notions or common sense, we utilize skills honed based on free thinking to manufacture cutting tools with a "technology" that combines ideas, creativity, and skill into a unified whole. 【Features】 ■ Responds to a variety of materials such as high-speed steel, powdered high-speed steel, and die steel ■ Capable of producing cutting tools in a wide variety of shapes by shaping and grinding grinding wheels ■ Utilizes skills honed based on free thinking ■ Manufactures cutting tools with a "technology" that combines ideas, creativity, and skill into a unified whole *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Komori Seiki, we grind plates with a thickness to length ratio of over 40 times to a flatness of 0.02 or less. By properly managing distortion (from material, heat treatment, chucking, processing, and internal stress), we provide the desired precision. The hardened steels include SK, SKS, SKD, SKH, and HAP, while the non-magnetic materials consist of SUS and aluminum alloys. 【Features】 ■ Hardened steel: SK, SKS, SKD, SKH, HAP ■ Non-magnetic: SUS, aluminum alloys *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Komori Seiki, we have been processing industrial cutting tools since our establishment. We have accumulated various know-how regarding the material, hardness, angle, and thickness of the blades in-house. We propose suitable cutting tools that match the workpiece. 【Processed Products】 ■ Cutters for wire harnesses ■ Cutters for catheters ■ Blades for packaging machines ■ Woodworking blades ■ Special cutting tools ■ Grinding tools *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We are constantly collaborating with over 70 partner companies. We perform anodizing and electroless nickel plating on aluminum products, separating the areas. After nitriding treatment, we apply electroless nickel plating to the workpieces, digitizing thermal changes for each material and conducting appropriate heat treatment. 【Features】 ■ Anodizing and electroless nickel plating on aluminum products are performed separately by area. ■ Electroless nickel plating is applied to workpieces after nitriding treatment. ■ Hard chrome plating in units of 1μm. ■ Thermal changes are digitized for each material, and suitable heat treatment is conducted. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce a case study in "Ultra-precision machining × ultra-precision measurement." There were products that became difficult to process for 12 other companies in the same industry, but we cleared the requirements (dimensional tolerances, roundness, cylindricity) on the first attempt. Our technical capability is due to the alignment of the "measuring standards" between the machinist and the measurer. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Komori Seiki, we have extensive experience in cutting and grinding processes after bonding and crimping iron and dissimilar materials. We can also handle welding of iron to iron and brazing of carbide materials. Please feel free to consult us when you need our services. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

KOMORI has ultra-precision measurement technology with a resolution of 0.1μm. It is a technology that eliminates "uncertainty" associated with measurements as much as possible and measures absolute values. We carefully remove the uncertainties related to temperature, humidity, product clamping, and measurement techniques, and finally conduct measurements in a natural and simple manner. Please feel free to consult us when you need our services. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The technology for polishing metal surfaces and imparting special properties is used in mold components, gauges, and functional parts. Lapping involves sequentially increasing the grit of a paste mixed with diamond powder (making it finer) to change the surface characteristics. Mirror finishing, which creates a mirror-like surface, is representative of this process. For appropriate material selection, unique lapping methods, and the production of lapping jigs, please consult KOMORI. *For more details, please refer to the PDF materials or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When processing metal, deformation due to structural changes inevitably occurs. There are deformations that remain internally (internal stress), deformations caused by frictional heat during processing, deformations due to chucking, and deformations due to structural changes from heat treatment. While the degree of deformation can vary, properly managing deformation affects processing accuracy, and especially in processing at the 1μm level, even a slight deformation can impact critical parts of the product. KOMORI has a unique deformation correction technology developed through its original business of blade processing. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Technological innovation can be achieved through "free thinking and a spirit of challenge" that is not bound by established concepts. With this mindset, we have realized "micron-level processing technology," and the high-precision, complex-shaped parts we produce are delivered and contribute to a wide range of fields, including electronics, electrical engineering, machinery, molds, jigs, tools, and measuring instruments. Komori Seiki is a high-level group of engineers that provides a more precise environment across all technical fields. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Komori Seiki Co., Ltd. is a technology development-oriented company founded in May 1972, aiming to grow as a brain-intensive technology group. We have introduced world-class machine tools that enable ultra-precision processing, producing high-quality products through excellent technology. Additionally, we have established a quality assurance system and are committed to pursuing customer satisfaction. Our factory is equipped with heating and cooling systems, and all our products are in cutting-edge industrial fields. Moving forward, we will continue to enhance our human resources and equipment, striving further in research and development of technology, and serving society. 【Business Activities】 - Design and manufacturing of industrial cutting tools, jigs, and gauges - Design and manufacturing of measuring jigs - Precision assembly - Ultra-precision machine parts - High-precision mold parts and press molds For more details, please contact us or download our catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration