1~45 item / All 45 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~45 item / All 45 items

Namtechno utilizes wire cut electrical discharge machining and fine hole electrical discharge machining technologies to manufacture precision molds for semiconductor-related components and electronic parts, which are becoming increasingly compact. Additionally, we excel in complex and delicate processing of precision tools and components using the ultra-fine technology developed through mold manufacturing, and our products are active in various fields. "Wire Electrical Discharge Machining" We perform precise metal processing using wires with a minimum diameter of 0.02 mm. This enables ultra-fine and delicate processing. Corner R: 0.015 mm ⇒ Achieving shapes close to pin angles! Slit width: 0.03 mm ⇒ Processing from one location on products or tools! For component processing and test pieces! Minimum lot size of one and processing from one location! Please feel free to contact us first.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The wire electrical discharge machining technology introduced this time is... 'Puzzle (4-piece version)' The die and punch are processed from separate workpieces. The shape of the die is gradually adjusted to fit perfectly, to the extent that the separate workpieces cannot be visually confirmed. The gap between the die and punch is '5μm', and using this processing technology, we create precision and micro-machined products. This processing technology allows 'four pieces of the puzzle' to emerge from a solid workpiece that has not been machined at all, and this technology is active in various fields such as precision mold creation and micro-machining for products! We perform micro-machining in a wide range of fields, including precision machining of medical devices (the tip of an endoscope), electronic components for mobile devices, cutting out test pieces, semiconductor components, and automotive parts! [Features] ■ Minimum wire diameter: Compatible up to φ0.02mm (20μm) (wire electrical discharge machining) ■ Minimum hole diameter: Compatible up to Φ0.02mm (20μm) (fine hole electrical discharge machining) ■ Precision molds, precision mold components, pipe machining, test pieces, semiconductor components, etc. ■ Compatible with difficult-to-cut materials *For more details, please refer to the case study available for download or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Namtech's electrical discharge machining (EDM) is capable of processing a wide variety of materials, including high-hardness and high-melting-point materials, thanks to years of know-how and experience. 【Examples of Processed Materials】 ■ Steel ■ Stainless Steel ■ Aluminum ■ Copper ■ Carbide ■ Tungsten ■ Tantalum ■ Molybdenum ■ Titanium ■ Ceramic (conductive) ■ Zirconium ■ Niobium ■ Hafnium Materials that cannot be processed by cutting can be finely machined using electrical discharge machining. We perform precision (micro) machining in a wide range of fields, including medical devices (tips of endoscopes), electronic components for mobile phones, cutting of test specimens, semiconductor parts, and automotive components. 【Features】 ■ Minimum wire diameter: down to φ0.02mm (20μm) (wire EDM) ■ Minimum hole diameter: down to φ0.02mm (20μm) (fine hole EDM) ■ Precision molds, precision mold parts, pipe processing, etc. *For more details, please refer to our case study collection available for download or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The technology of "Wire Electrical Discharge Machining" introduced this time is... "Uneven Shape Machining (Taper Machining)" The original purpose of taper machining is to create a slope (relief) on the die shape side to make it easier to extract products from press molds. We are performing advanced uneven shape machining using taper machining technology. The processed item this time has a top surface shaped like a "circle" and a bottom surface shaped like a "square." The maximum taper angle is about 15 degrees. Within that range, various shapes can be machined! [Features] ■ Maximum taper angle of about 15 degrees ■ Machining with uneven shapes on the top and bottom surfaces ■ Compatible with difficult-to-cut materials *For more details, please contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Electrical discharge machining" allows for fine processing that cannot be achieved with cutting machines. This introduction to processing technology features the character "0.02" in the photo. It is not visible to the naked eye unless light is shone from below the workpiece. Holes measuring "0.02mm" have been processed in "75 locations" with precision, making the characters stand out! Furthermore, the surrounding lines are processed with a "0.02mm" wire electrical discharge machining, achieving a slit width of "0.025mm"! Fine processing that cannot be done with cutting machines is possible. We perform processing in a wide range of fields, including medical devices (such as the tips of endoscopes), electronic components for mobile phones, semiconductor parts, and automotive components. 【Features】 ■ Capable of ultra-small diameter processing ■ Capable of ultra-small slit processing ■ Compatible with difficult-to-cut materials ■ Minimum hole diameter φ0.02mm ■ Minimum wire diameter φ0.02mm *For more details, please refer to the catalog. Feel free to contact us with any inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Fine and small-diameter pipes used in medical devices With Namtechno! Precision machining is possible on the tips and sides using wire electrical discharge machining and fine hole electrical discharge machining! Issues such as workpieces bending, crushing, burrs appearing, and difficulties in machining due to vibrations, etc., "Drilling holes," "slitting," "creating steps," "adding grooves," "fine machining," "irregular shapes," "burr-free hole machining," "burr-free shape machining." Please consult Namtechno once! We can process and manufacture from one part or one hole, and test machining is also possible! The types of wire handled by Namtechno are: 0.02mm, 0.03mm, 0.05mm, 0.07mm, 0.1mm, 0.2mm, 0.25mm. We respond to a wide range of customer needs! *For more details, please contact us or refer to the related links.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are you familiar with the special metals "Tantalum" and "Hafnium"? "Tantalum" and "Hafnium" are metals that do not pose a risk of metal allergies and are used in rings. Additionally, they are characterized by their hardness and ductility, making them difficult to machine. At Namutecno, we can handle everything from material procurement of special materials like "Tantalum" and "Hafnium" to precision machining. We can process not only ring shapes but also a variety of other shapes! 【Why Namutecno can process these materials】 ■ We use methods suitable for materials that are not machined, such as wire processing and electrical discharge machining. ■ We process without creating burrs, thanks to our years of accumulated know-how and technology. ■ We can handle not only processing but also material procurement. *For more details, please refer to our case study collection available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Wire processing" is a type of electrical discharge machining that uses thin brass wire as an electrode, allowing for high-precision shaping regardless of the hardness of the workpiece, while minimizing the amount of material removed from the workpiece. At Namtechno, we can process using fine wire with diameters of φ0.07 mm, φ0.05 mm, φ0.03 mm, and φ0.02 mm. [Processing Example] Processing Method: Wire cut electrical discharge machining using ultra-fine wire Processed Product: Slit processed product with a width of 25μ (0.025 mm) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Namtech's "Precision Machining Case Studies" is a collection of examples showcasing various processed products made using wire cutting and fine hole discharge machining, including molds, mold components, pipe processing, punches, jigs, and fine pins, in various shapes and materials. It features over 50 examples of diverse processed products, including precision machined items with a minimum hole diameter of 20μm and M1 tapped products. The fine hole discharge machining has achieved a minimum hole diameter of 20μm! Wire discharge machining: Minimum wire diameter [20μm (0.02mm)] Fine hole discharge machining: Minimum hole diameter [20μm (0.02mm)] [Contents of the Case Studies] ■ Examples of fine hole discharge machining and wire cutting ■ Precision molds and precision mold components ■ Punches ■ Fine pins ■ Stainless steel jigs ■ Pipe processing ■ Tapping processing ■ Examples of machining difficult materials such as molybdenum, tantalum, and tungsten *For more details, please refer to the case studies available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

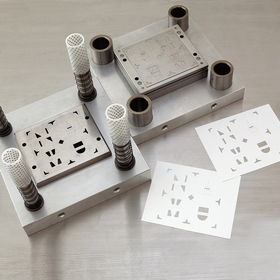

Namtech's "Mold Manufacturing for Green Sheets" is suitable for green sheets, TAB tapes, and films for punching, punching, and pressing. We utilize the know-how gained from our achievements in mold manufacturing for electrical and electronic components, as well as wire-cut electrical discharge machining and fine hole electrical discharge machining, to produce finely detailed and precise molds for green sheets. 【Catalog Contents】 ■ Microprocessing ■ Product Introduction and Processing Examples ■ Namtech's Ideas ■ Namtech's Equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Namtech's "Film Mold Manufacturing" produces molds suitable for punching, punching, and pressing for film, TAB tape, and green sheets. Utilizing the know-how gained from our achievements in manufacturing molds for electrical and electronic components, we create fine and precise molds for films using wire cut electric discharge machining and fine hole electric discharge machining. 【Catalog Contents】 ■ Micro Processing ■ Product Introductions and Processing Examples ■ Namtech's Ideas ■ Namtech's Equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Namtech's "TAB Tape Mold Production" is a mold suitable for TAB tape, film, and green sheet for punching, punching, and pressing. We utilize the know-how gained from our track record in manufacturing molds for electrical and electronic components, along with wire-cut electric discharge machining and fine hole electric discharge machining, to produce finely detailed and precise molds for TAB tape. 【Catalog Contents】 ■ Ultra-small processing ■ Product introduction and processing examples ■ Namtech's ideas ■ Namtech's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of high-precision "irregular punches" processed and manufactured using wire cut electrical discharge machining and fine hole electrical discharge machining. Additionally, precision parts can be produced using these techniques. ◆ We are currently offering a free collection of case studies featuring outstanding precision products! ◆ 【Contents of the Case Study Collection】 ■ Examples of fine hole electrical discharge machining and wire cutting ■ Precision molds and precision mold parts ■ Punches ■ Fine pins ■ Stainless steel jigs ■ Pipe processing ■ Tapping ■ Examples of processing difficult materials such as molybdenum, tantalum, and tungsten *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are you familiar with the special metal "Tantalum"? Tantalum is a metal that does not cause metal allergies and is used in rings. Additionally, it is characterized by its hardness and toughness, making it a difficult material to machine. At Namtechno, we can handle everything from material procurement to precision processing of the special material "Tantalum" in a consistent manner. 【Reasons We Can Process Tantalum】 ■ Manufacturing using methods suitable for Tantalum, such as wire processing and electrical discharge machining, rather than cutting. ■ Processing without producing burrs, thanks to our years of accumulated know-how and technology. ■ Not only processing but also material procurement is possible. *For more details, please refer to the case studies available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Namtechno, we conduct wire cut electrical discharge machining and fine hole electrical discharge machining of high melting point metals (difficult-to-cut and difficult-to-process materials) such as tungsten, molybdenum, and tantalum, including sales and processing. Due to their scarcity, we also offer material procurement and sales of tungsten, molybdenum, and tantalum. 【Case Study Collection Contents】 ■ Various processing details and production examples ■ Various materials and production examples We have published numerous achievements and case studies! *For more details, please refer to the case study collection available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Namtechno, we engage in the sale and processing of difficult-to-machine materials such as tungsten, molybdenum, and tantalum, as well as wire-cut electrical discharge machining and fine hole electrical discharge machining of high melting point metals (difficult-to-machine materials). Due to their scarcity, we can also procure and sell materials like tungsten, molybdenum, and tantalum. 【Case Study Collection Contents】 ■ Various processing methods and production examples ■ Various materials and production examples We have published numerous achievements and case studies! *For more details, please refer to the case study collection available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to the machining of parts that involves wire processing and tapping of ceramic materials. We can also procure materials for machining difficult materials such as molybdenum, tantalum, and tungsten. 【Contents of the Case Study Collection】 ■ Various machining processes and production examples ■ Various materials and production examples We have published numerous achievements and case studies! *For more details, please refer to the case study collection available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to fine hole processing for ceramic materials. We can also procure materials for machining difficult materials such as molybdenum, tantalum, and tungsten. 【Case Study Collection Contents】 ■ Various processing types and production examples ■ Various materials and production examples And many more achievements and examples are included! *For more details, please refer to the case study collection available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to processing square holes in ceramic materials. We can also procure materials for machining difficult-to-cut materials such as molybdenum, tantalum, and tungsten. 【Contents of the Case Study Collection】 ■ Various processing methods and production examples ■ Various materials and production examples We have published numerous achievements and case studies! *For more details, please refer to the case study collection available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Namtech's "Precision Machining Case Studies" is a collection of examples showcasing various processed products made using wire cutting and fine hole discharge machining, including molds, mold components, pipe processing, punches, jigs, and fine pins, in various shapes and materials. It features over 50 examples of diverse processed products, including precision machined items with a minimum hole diameter/minimum line diameter of 20μ (0.02mm) and M1 tapped products. [Contents: Examples of fine hole discharge machining/wire cutting] ■ Precision molds and precision mold components ■ Punches and fine pins ■ Stainless steel jigs ■ Pipe processing and tapping ■ Machining of difficult materials such as molybdenum, tantalum, and tungsten *For more details, please download the case study from the PDF materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Namtechno, we conduct wire cut electrical discharge machining and fine hole electrical discharge machining of high melting point metals (hard-to-machine materials) such as tungsten, molybdenum, and tantalum, as well as their sales and processing. Due to their scarcity, we can also procure and sell materials of tungsten, molybdenum, and tantalum. 【Case Study Collection Contents】 ■ Various processing details and production examples ■ Various materials and production examples We have numerous achievements and examples published! *For more details, please refer to the case study collection available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Using Namtechno's molds, it is possible to process ceramic green sheets as well. At Namtechno, we perform "precision processing" utilizing wire cutting and other techniques based on precision mold technology. We respond to diverse requests in a well-equipped environment. 【Features】 ■ Application of precision mold technology ■ Utilization of wire cutting and fine hole discharge machining ■ Minimum wire diameter: 20μ ■ Minimum hole diameter: 20μ *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The comprehensive catalog is a catalog that includes Namtechno's business activities and technologies, as well as examples of each product's manufacturing. [Contents] ■ Micro machining ■ Product introductions and processing examples ■ Namtechno's ideas ■ Namtechno's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Namtechno utilizes wire cut electrical discharge machining and fine hole electrical discharge machining technologies to manufacture precision molds for semiconductor-related components and electronic parts, which are becoming increasingly compact. Additionally, we excel in complex and delicate processing of precision tools and parts using the ultra-fine technology developed through mold manufacturing, and our products are active in various fields. 【Namtechno's Technologies】 (1) Wire Electrical Discharge Machining We use wires with a minimum diameter of 0.02 mm for precise metal processing, enabling ultra-fine and delicate machining. (2) Fine Hole Electrical Discharge Machining We can perform ultra-small diameter (minimum hole diameter of 0.02 mm) machining that cannot be achieved with cutting machines, allowing for delicate hole drilling even in difficult-to-cut materials (metals). We can manufacture and process from one part to one hole. If you have any issues with precision molds or precision machining, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Namtechno utilizes wire cut electrical discharge machining and fine hole electrical discharge machining technologies to manufacture precision molds for semiconductor-related components and electronic parts, which are becoming increasingly compact. Additionally, we excel in complex and delicate processing of precision tools and components using the ultra-fine technology developed through mold manufacturing, and our products are active in various fields. [Namtechno's Technology] Precision Mold Manufacturing… We produce precision molds using wire electrical discharge machining and fine hole electrical discharge machining technologies! We can manufacture and process from one part to one hole. If you have any issues with precision molds or precision processing, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Wire processing" is a discharge machining method that uses thin brass wire as an electrode. It allows for the workpiece to be cut into various shapes, similar to using a scroll saw. The wire can also be tilted using a tapered shaft, expanding the variety of machining shapes. High-precision shapes can be processed regardless of the hardness of the workpiece, and the amount of material removed from the workpiece is minimal. 【Features】 ■ Ability to cut into various shapes ■ Wire can be tilted using a tapered shaft ■ High-precision shapes can be processed regardless of workpiece hardness ■ Reduction in the amount of material removed from the workpiece ■ Various shapes can be processed using only one type of wire *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In "fine hole discharge machining," extremely small diameter processing that cannot be achieved with cutting machines can be performed. It is also compatible with difficult-to-cut materials such as metals. Processing of a minimum hole diameter of φ0.02mm is possible. 【Features】 ■ Capable of extremely small diameter processing ■ Compatible with difficult-to-cut materials ■ Minimum hole diameter of φ0.02mm *For more details, please refer to the catalog. Feel free to contact us as well.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Namtech Co., Ltd., we perform two types of "fine hole processing": processing using fine hole discharge and processing using wire cut discharge. In fine hole discharge, we can achieve a minimum diameter of φ0.02mm, and in wire cut discharge, we can also achieve a minimum diameter of φ0.02mm. *For more details, please refer to our catalog. Feel free to contact us as well.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Namtechno's products" are active in various fields, including miniaturized semiconductor-related components and electronic parts. We handle a wide range of products, including die set molds, molds for punching machines, and precision parts. *For more details, please refer to the catalog. Feel free to contact us as well.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We are engaged in the processing of tungsten, a high melting point metal. Two types of processing methods are available: wire processing and fine hole discharge machining. In addition to processing, we also handle procurement and sales. *For more details, please refer to the catalog. Feel free to contact us with any inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Namtech Co., Ltd. specializes in the world of extremely small holes with a minimum diameter of just 0.02mm, utilizing technologies such as wire-cut electrical discharge machining, micro-hole processing, and fine hole electrical discharge machining to manufacture precision molds for semiconductor-related components and electronic parts, which are becoming increasingly compact. Products leveraging Namtech's technology are active in various fields, including semiconductor-related components and electronic parts. The precision molds created by Namtech are delivered not only within Japan but also to countries around the world. We believe that our ultra-small technology will surely contribute to the development of fields yet to be encountered. Namtech assists in the evolution and improvement of your products through original manufacturing. If you have any concerns regarding precision molds or precision processing, please feel free to contact us. 【Product Introduction】 ○ Precision Molds ○ Fine Hole Processing ○ Wire-Cut Processing ○ Fine Hole Electrical Discharge Processing For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of parts processing and manufacturing using wire cut electrical discharge machining and fine hole electrical discharge machining. We manufacture die set mold parts such as ceramic green sheets, TAB tapes, substrates, and thin plates. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ Ultra-small processing ■ Product introductions and processing examples ■ Namtechno's ideas ■ Namtechno's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of parts processing and manufacturing using wire cut electrical discharge machining and fine hole electrical discharge machining. We manufacture mold components for punching machines, including ceramic green sheets, TAB tapes, substrates, and thin plates. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ Ultra-small processing ■ Product introductions and processing examples ■ Namtechno's ideas ■ Namtechno's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of parts processing and manufacturing using wire cut electrical discharge machining and fine hole electrical discharge machining. We manufacture fine hole punching dies and die components for punching machines. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ Ultra-small processing ■ Product introduction and processing examples ■ Namtechno's ideas ■ Namtechno's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of parts processing and manufacturing using wire cut electrical discharge machining and fine hole electrical discharge machining. We manufacture molds and mold parts for punching machines. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ About ultra-small processing ■ Product introductions and processing examples ■ Namutec's ideas ■ Namutec's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of parts processing and manufacturing using wire electrical discharge machining for "slit processing." Additionally, precision parts can be manufactured using wire cut electrical discharge machining and fine hole electrical discharge machining. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ Ultra-small processing ■ Product introductions and processing examples ■ Namtech's ideas ■ Namtech's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of parts processing and manufacturing for "pipe end processing and side processing" using wire electrical discharge machining and fine hole electrical discharge machining. Additionally, precise parts manufacturing is possible by utilizing wire cut electrical discharge machining and fine hole electrical discharge machining. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ Ultra-small processing ■ Product introduction and processing examples ■ Namtechno's ideas ■ Namtechno's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of parts processing and manufacturing using electrical discharge machining for difficult-to-cut materials such as superhard materials and hard-to-machine materials, specifically "tapping processing." Amazingly, we can also process fine female threads starting from M1! Additionally, we can manufacture precision parts using wire-cut electrical discharge machining and fine hole electrical discharge machining. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ Micro machining ■ Product introductions and processing examples ■ Namutec's ideas ■ Namutec's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Namtechno, we conduct wire cut electrical discharge machining and fine hole electrical discharge machining for high melting point metals (difficult-to-cut and difficult-to-process materials) such as tungsten, molybdenum, and tantalum, including sales and processing. Due to their scarcity, we also offer material procurement and sales for tungsten, molybdenum, and tantalum. ◆ We are currently offering a comprehensive catalog featuring case studies for free! ◆ 【Catalog Contents】 ■ Micro machining ■ Product introductions and processing examples ■ Namtechno's ideas ■ Namtechno's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of parts processing and manufacturing of "ultra-small pins (minimum 10μ or larger)" using wire cut electrical discharge machining and fine hole electrical discharge machining. Amazingly, we can also process fine female threads starting from M1! Additionally, we can manufacture precision parts utilizing wire cut electrical discharge machining and fine hole electrical discharge machining. ◆ Right now, we are giving away a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ About ultra-small processing ■ Product introductions and processing examples ■ Namutec's ideas ■ Namutec's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of parts processing and manufacturing of "high-precision punch and die fitting" using wire electrical discharge machining. Additionally, we can manufacture precision parts utilizing wire cutting and fine hole electrical discharge machining. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ Micro machining ■ Product introductions and processing examples ■ Namtechno's ideas ■ Namtechno's equipment *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of high-precision parts processing and manufacturing of "round pins, punches, irregular pins, punches, and square pins, punches" using wire cut electrical discharge machining and fine hole electrical discharge machining. Additionally, precision parts manufacturing is possible by utilizing wire cut electrical discharge machining and fine hole electrical discharge machining. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ About ultra-small processing ■ Product introductions and processing examples ■ Namutec's ideas ■ Namutec's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to examples of parts processing and manufacturing of "processing for conductive ceramics" using wire cut electrical discharge machining and fine hole electrical discharge machining. Additionally, precise parts manufacturing is possible by utilizing wire cut electrical discharge machining and fine hole electrical discharge machining. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ 【Catalog Contents】 ■ Ultra-small processing ■ Product introductions and processing examples ■ Namtechno's ideas ■ Namtechno's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Wire cut electrical discharge machining for 'shear angle processing on corner punches' This is an introduction to our parts processing and manufacturing examples. Additionally, we can manufacture precision parts using wire cut electrical discharge machining and fine hole electrical discharge machining. ◆ We are currently offering a comprehensive catalog featuring manufacturing examples for free! ◆ [Catalog Contents] ■ Ultra-small processing ■ Product introductions and processing examples ■ Namtechno's ideas ■ Namtechno's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introduction of "Seat Grinding and Dish Seat Grinding Processing" through Electrical Discharge Machining for Superhard Materials. This is a case study of parts processing and manufacturing. Additionally, we can manufacture precision parts using wire-cut electrical discharge machining and fine hole electrical discharge machining. ◆ We are currently offering a comprehensive catalog featuring case studies for free! ◆ 【Catalog Contents】 ■ Ultra-small processing ■ Product introduction and processing examples ■ Namtech's ideas ■ Namtech's equipment *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration