1~5 item / All 5 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~5 item / All 5 items

Fast IoT is a monitoring system equipped with a wireless unit. It enables monitoring and recording of production numbers, downtime, and operational status from all operational manufacturing equipment, regardless of manufacturer, model, or age of the equipment. 【Features】 1. Easy to implement - Compatible with each manufacturing device - Compatible with installed devices / No restrictions on equipment manufacturers / Compatible with older devices 2. Low cost No need for equipment replacement / No monthly costs / No additional construction required 3. Comprehensive data collection Understand the operational status of the equipment Aggregate operational rates Aggregate actual cycle times by part number Aggregate reasons for downtime *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Fast IoT is a monitoring system that adds a special wireless unit to an already proven IoT monitoring system, eliminating the need for traditional LAN construction. It is easy to implement. It consists of sensors, a wireless unit, a controller, and software (with a 3-year license) that supports one manufacturing device, and can accommodate up to six devices per controller. Additionally, by connecting multiple controllers to the customer's network, it can be used for systems with up to 100 devices. Without constraints related to manufacturers, models, or the age of the equipment, it enables monitoring and recording of production numbers, downtime, and operational status from all operational manufacturing devices. Implementation results of the traditional system (without wireless units): Company R (parts manufacturer) - Number of units implemented: 59 Analyzed reasons for downtime based on data rather than intuition, made improvements starting from the most noticeable issues, and increased operational efficiency by over 5%. Displayed numerical data from each device at the work site, leading to increased awareness of operational efficiency during work, which improved the consciousness of the work environment and employees. Productivity improvements were also observed in devices not installed.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

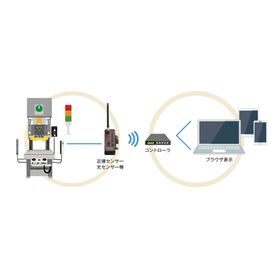

This is an IoT system that allows remote confirmation of contact information for alarms and warnings from existing control panels. It can be displayed on a PC and can send emails. Early response and analysis of troubles are possible! This system centrally manages information from contacts connected to alarm lamps and other devices in control panels for equipment management, and displays and analyzes it via a browser on a PC or tablet. It automatically retrieves the history of equipment anomalies outputted to the contacts and generates a history report. The information from the contacts can be sent to a specified email address by turning the notification function ON or OFF. The display content and email sending content can be set and changed as desired.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At EL System, we offer IoT system prototyping services for the manufacturing industry. We can provide cost-effective systems at low prices and short delivery times, and the information necessary for productivity management can be customized according to customer requests. Data acquisition is facilitated by retrofitted sensors, making it easier to coexist with existing equipment. If data can be obtained from existing equipment, it can also be utilized. 【Service Details】 ■ Provided Functions: Compatible with both local environments and the cloud Data acquisition, DB storage, real-time display, alert notifications, etc. ■ System Configuration: General-purpose sensor module + microcontroller board ■ Cost: Approximately 250,000 to 750,000 yen (Delivery time: 1 to 3 weeks) ■ Communication Lines: 3G, LTE: SORACOM Air, etc. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an intelligence wireless module equipped with the TI CC1310 SimpleLink Sub-1 GHz ultra-low power wireless microcontroller. It can be controlled via a serial interface from the main board. Additionally, since it has an ARM Cortex-R3 built-in, it can operate independently by implementing applications. (Manufactured by K2 Electronics Industry) At the request of our customers, we offer customization options such as low power consumption support and low latency support.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration