- Publication year : 2025

1~9 item / All 9 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~9 item / All 9 items

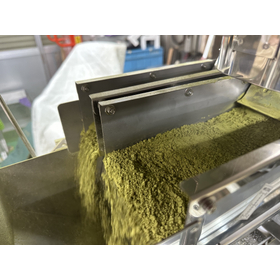

Hello! For everyone involved in the food manufacturing industry dealing with powders, "high-precision measurement for matcha and powder" is an essential issue that cannot be overlooked. Today, I will thoroughly explain the latest technology that dramatically improves this challenge in a way that anyone can understand. - The dust is rising, worsening the working environment. - Changes in humidity cause the powder to bridge, halting production. - I want to reduce the loss of expensive matcha raw materials. - I want to measure more efficiently and accurately. If you are facing these concerns, this article is written just for you. Knowledge you will gain from this article: We will provide overwhelming information exceeding 5,000 words on feeder-type weighing machines for matcha and powders, covering everything from basic knowledge to the latest technology, implementation effects, and practical operational know-how. By the time you finish reading, you should have a clear path to solving the challenges of powder measurement!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

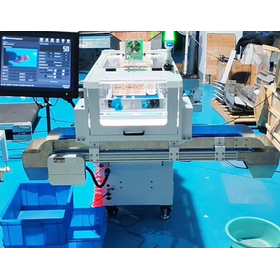

Hello! Today, I will explain in an easy-to-understand manner why AI is necessary for camera-based image processing parts counters. This is an important topic for those involved in manufacturing and parts management, so please read until the end. Counting in the era of factory automation: What it means Basic principle of camera-based parts counters A camera-based parts counter is a device that automatically counts the quantity of parts based on images captured by a camera. It takes pictures of falling parts and numbers their silhouettes to count them.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the manufacturing industry, parts counters have been designed for many years based on the fundamental principle of "separating individual components and aligning them in a row for counting." However, the VST-type parts counter was born as a completely new "concept" device that fundamentally overturns this conventional wisdom. The new concept proposed by the VST type is a new paradigm for parts counting that emphasizes "distribution" instead of "separation," "flow" instead of "alignment," and "composite control" instead of "single control."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"This parts counter has an accuracy of 99.98%." When you receive this explanation from the sales representative, what do you imagine? Many people understand it as "out of 1000 pieces, 998 are accurate," but this is not correct. The accuracy of a parts counter consists of two different concepts: **"identification accuracy" and "control accuracy."** If you introduce it without understanding this difference, you may end up in a situation where "the catalog value is high precision, but in the actual field, over-counting occurs frequently." Matsuraku Industries has been manufacturing feeder-type weighing machines for over 60 years. In this article, we will clearly explain these two concepts of accuracy based on the insights gained from our extensive experience.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To all those in the food manufacturing sector of small and medium-sized enterprises, are you struggling with daily weighing tasks? "Simple weighing tasks are taking up too much manpower." "Weighing by hand limits production speed." "But large-scale and expensive automation is difficult..." Chronic labor shortages: "No one is coming to do the weighing and packing tasks." By reading this article, you will understand everything about **Shouraku Sangyo's 'Feeder Type Weighing Machine'**, which can solve these issues, and you will see a clear path to improving your company's productivity. We will comprehensively explain the benefits of implementation and the unique strengths of Shouraku Sangyo for everyone in the food industry.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introduction: Challenges Faced by Counting Operations in Manufacturing Sites Manufacturers, do you face any troubles with daily parts management or production management? "Although we use counters for screws, bolts, and nuts, the accuracy is insufficient." "Counting parts manually takes too much time." "Weight-based counters do not function accurately for parts with individual differences." "We want to use it for picking with a target value of around 100 pieces." "Due to the Toyota Production System, the number of bags for individual packaging is small." Mistakes in counting operations in manufacturing can lead to losses amounting to hundreds of millions of yen annually. Especially in recent years, due to labor shortages, conducting high-precision parts quantity counting with limited personnel has become an urgent issue for many manufacturing sites. Even if you are considering introducing a picking counter, many may be unsure about which counting machine to choose. Rest assured. With the latest AI-equipped camera-based parts counters, these challenges can be dramatically improved. In this article, we will provide all the necessary information for manufacturers regarding the latest counting machines that utilize image processing technology and AI control, from their mechanisms to how to choose them.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Table of Contents 1. Basic Edition: Fundamental Knowledge of Counting Machines and Parts Counters 2. Accuracy Edition: Questions Regarding Counting Accuracy 3. Technical Edition: About Control Accuracy and Recognition Accuracy 4. Material and Shape Edition: Compatible Parts 5. Model Selection Edition: How to Choose the Optimal Model 6. Introduction Edition: From Testing to Implementation

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Hello! To everyone involved in daily weighing tasks in food manufacturing, do you have any of these concerns? "Weighing by hand takes too much time," "We are struggling with a labor shortage," "But large-scale capital investment is difficult..." In this Q&A collection, we will clearly answer all your questions about feeder-type weighing machines. We have comprehensively compiled information that those in the food industry want to know, from the basic mechanisms to the benefits of introduction, costs, and maintenance. Please read to the end!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

What is a counting machine and parts counter? / Do you really understand the accuracy of parts counters? A thorough explanation of "identification accuracy" and "control accuracy" The truth about counter accuracy that manufacturing site managers should know ________________________________________ "The accuracy of the counter is 99.8%." When you receive such an explanation, do you fully understand it? In fact, the "accuracy" of a parts counter consists of two important concepts: **"identification accuracy" and "control accuracy."** If you introduce a counter without understanding these two, you might end up in a situation where "the catalog value is high precision, but the actual accuracy is not as expected." This article will explain the accuracy of parts counters in an easy-to-understand manner without using technical jargon, which factory site managers should grasp. [What you will learn from this article] • The difference between identification accuracy and control accuracy • Why overall accuracy decreases • The challenges of control based on the material of the parts • Key points to avoid failure in model selection

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration