46~90 item / All 115 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF46~90 item / All 115 items

We received a request from a customer regarding "small-scale prototypes." The content is, "I want to produce at least one prototype for product announcements at overseas exhibitions." In our company, we will consider methods with the customer that do not incur initial costs, using brakes, rolls, and handwork for production without molds, except for absolutely necessary parts. 【Proposal】 ■ Production using brakes, rolls, and handwork without molds ■ Consideration of methods that do not incur initial costs with the customer ■ Results - Production prioritized on delivery time and cost - Production for shape confirmation in the preliminary stage before product development - By producing and installing the actual item, various improvement points became clear, speeding up design improvements *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】Mold Production At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to produce prototype sheet metal for research and development, automotive prototype sheet metal, mold production, precision sheet metal, and other applications. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】Foot Hinge At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, precision sheet metal, and other products. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for reducing costs and improving quality from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】Dog Cage At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, precision sheet metal, and other products. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】Tailgate Hinge At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, precision sheet metal, and other products. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】Duct At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, precision sheet metal, and more. *For additional information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】Gate Lock At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】Air Conditioning Parts At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal Processing Example】Aluminum 0.4mm Fuel Tank At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, precision sheet metal, and more. *For additional information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We received a request from a customer regarding the "processing method." The content is: "Currently, we are designing the product, but we are unsure if the product design we are considering can be processed by pressing, so we would like to consult for now." At Hayano Kanko, we will provide a brief explanation of the drawing processing method using pressing in our process and, based on our experience, we will consult on the labor hours and risks to the extent that we can understand. 【Proposal】 ■ A brief explanation of the drawing processing method using pressing in our process ■ Consultation on labor hours and risks based on our experience ■ It is also possible to obtain backing through CAE analysis ■ Results - Considering design and processability, we conducted mold production while fully considering processing characteristics through CAE analysis - We were able to produce a satisfactory design in a single drawing process *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Sheet Metal and Processing Examples】ASSY Jigs At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, precision sheet metal, and other products. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. The handbook is filled with useful information for cost reduction and quality improvement from the perspective of a manufacturing company regarding sheet metal design!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Laser Processing Example】 Metal Shogi Pieces At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture a variety of products, including prototype sheet metal for research and development, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

[Laser Processing Examples] Metal Parts (SUS) At Hayano Kenco, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenco's expertise, please refer to the handbook available for download. The handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We received a request from a customer regarding "cost reduction." The content is as follows: "Currently, for products processed by bending and welding sheet materials, we cannot reduce costs due to the high number of welding processes. Is there any way to reduce the welding processes?" Our company will consider using pressing for drawing and bending processes, and even if we cannot fully convert the entire product, we will think about cost reduction by partially implementing pressing. 【Proposal】 ■ Consider drawing and bending processes using pressing ■ Think about cost reduction by partially implementing pressing ■ We are also open to consultations regarding shape considerations related to design changes ■ Results - Successfully reduced mold investment and lowered product unit costs - Able to lower product unit costs by utilizing laser stacking molds, etc. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

[Laser Processing Example] Metal Mahjong Tile (SUS) At Hayano Kenko, we utilize our expertise in welding technology, 3D laser processing technology, and more to manufacture a variety of products, including prototype sheet metal, research and development prototypes, automotive prototype sheet metal, mold production, and precision sheet metal. *For more information on Hayano Kenko's expertise, please refer to the handbook available for download. This handbook is filled with useful information for manufacturers regarding sheet metal design, aimed at reducing costs and improving quality!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Fiber Laser Punching Hybrid Machine" is a hybrid machine that enables high-speed processing with fiber processing technology, capable of processing materials that cannot be processed with CO2 laser cutting. The production line features a two-shelf system with a material shelf and a product/skeleton shelf, allowing for continuous operation with multiple materials and products. This achieves low-cost processing. With one-shot nesting, it processes the appropriate quantity at the right timing. By utilizing a take-out device, products can be transported without dragging them, in a jointless manner. Additionally, automatic operation allows for unmanned processing at night. We provide exceptional cost competitiveness. 【Laser Cutting Specifications】 ■ Nitrogen (PSA device) cutting (clean cut) ■ Oxygen cutting (eco cut) ■ Air cutting *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Hayano Kenco specializes in the production of automotive prototype sheet metal, achieving high precision, short delivery times, and a variety of products. It is a company focused on metal processing centered around prototype sheet metal. "Special Material Composite Processing" is a technology that enables high-speed processing using fiber processing machines, allowing for the processing of materials that cannot be processed with CO2 laser cutting. With the installation of a nitrogen generation system, clean cuts can be achieved for SUS up to 6mm and SP up to 3.2mm. Additionally, brass, nitrogen, and copper can be processed using oxygen, enabling processing that was not possible with CO2. 【Laser Cutting Specifications】 ■ Nitrogen (PSA system) cutting (clean cut) ■ Oxygen cutting (eco cut) ■ Air cutting *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Hayano Kenco specializes in the production of automotive prototype sheet metal, achieving high precision, short delivery times, and a variety of products. It is a company focused on metal processing centered around prototype sheet metal. "2D processing" is handled by the Amada C1-AJ combined machine, which includes forming and tapping as part of its composite processing technology. In areas of processing that replace wire cutting, it is also capable of processing with a width of 0.15 mm. The cutting performance is remarkably sharp, surprising even the operators handling the machines. 【2D Processing Equipment】 ■ Equipment Name: Amada LC-2512-C1AJ *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Hayano Kenco specializes in the production of automotive prototype sheet metal, achieving high precision, short delivery times, and a variety of products. We are a metal processing company focused on prototype sheet metal. From 3D laser processing to handcrafted items, we propose prototypes tailored to our customers' needs. Our "3D processing" is supported by two Mitsubishi 3D laser processing machines, utilizing processing technology that accommodates large workpieces. We contribute to CAD operations using TEBIS, as well as workpiece fixation with cross-section jigs and clay jigs, and 3D laser processing. 【3D Processing Equipment】 ■ Equipment Name: Mitsubishi 2012HT 1508F ■ Machine Specifications - Oscillator: 800W, 5.0 inches, offset type processing head - Target Workpiece (3D): 1600 x 1000 x 450 (mm) - Maximum Workpiece for Flat Plate Processing: 2030 x 1250 (mm) - Table Load Capacity: 900 kg *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Hayano Kenco specializes in the production of automotive prototype sheet metal that achieves high precision, short delivery times, and a wide variety of products. We are a metal processing company focused on prototype sheet metal. From 3D laser processing to handmade products, we offer prototypes tailored to our customers' needs. Our "3D processing" is supported by two Mitsubishi 3D laser processing machines, utilizing processing technology that can handle large workpieces. We contribute to CAD operations using TEBIS, as well as workpiece fixation with cross-section jigs and clay jigs, and 3D laser processing. 【3D Processing Equipment】 ■ Equipment Name: Mitsubishi ML3122VZ2-20CF3 ■ Processing Machine Specifications - Oscillator: 2kW, 7.5-inch, offset type processing head - Target Workpiece (3D): 2600 x 1700 x 600 (mm) - Maximum Workpiece for Flat Plate Processing: 3100 x 2100 (mm) - Table Load Capacity: 2000 kg *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenko, we manufacture automotive prototype sheet metal that achieves high precision, short delivery times, and a variety of products. From 3D laser processing to handmade items, we propose prototypes tailored to our customers' needs. We would like to introduce a case study of our welding structural product, the "Welding Jig Base," which is centered around prototype sheet metal processing. 【Welding Structural Products】 ■ Welding Jig Base - Size: 900×600×500 - Material: SS400, S50C - Plate Thickness: 25–40mm - Lot: Single item - Delivery Time: 25–40 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenco, we manufacture automotive prototype sheet metal that achieves high precision, short delivery times, and a variety of products. From 3D laser processing to handmade items, we propose prototypes tailored to our customers' needs. We would like to introduce a case study of our welding structural products, focusing on prototype sheet metal processing, specifically our "Robot Welding Jigs." 【Welding Structural Products】 ■ Robot Welding Jig - Size: 1300×500×300 - Material: SS400, S50C, SKD - Plate Thickness: 25–40mm - Lot: Single item - Delivery Time: 25–40 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenko, we manufacture automotive prototype sheet metal with high precision, short delivery times, and a variety of products. From 3D laser processing to handcrafted items, we propose prototypes tailored to our customers' needs. We would like to introduce a case study of our welded structural product, the "Aluminum Inspection Jig Base," which focuses on prototype sheet metal and metal processing. 【Welded Structural Product】 ■ Aluminum Inspection Jig Base - Size: 2000×900×700 - Material: A5052P - Plate Thickness: 3–12mm - Lot: Single Item - Delivery Time: 2 weeks *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenco, we manufacture automotive prototype sheet metal that achieves high precision, short delivery times, and a variety of products. From 3D laser processing to handmade items, we propose prototypes tailored to our customers' needs. We would like to introduce a production example of our sheet metal processing product, "Cover for Commercial Air Conditioning Units," which focuses on prototype sheet metal. 【Sheet Metal Products】 ■ Cover for Commercial Air Conditioning Units - Size: 400×300×50 - Material: SGCC - Thickness: 1.2mm *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenco, we manufacture automotive prototype sheet metal that achieves high precision, short delivery times, and a variety of products. From 3D laser processing to handmade items, we propose prototypes tailored to our customers' needs. We would like to introduce examples of our sheet metal processing products, focusing on prototype sheet metal and our "welded products (mass production)." 【Sheet Metal Products】 ■ Welded Products (Mass Production) - Size: 700×500×400 - Material: SPHC - Plate Thickness: 2.3mm - Lot: 120/month *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenko, we manufacture automotive prototype sheet metal that achieves high precision, short delivery times, and a variety of products. From 3D laser processing to handmade items, we propose prototypes tailored to our customers' needs. We would like to introduce a case study of our sheet metal processing products, focusing on prototype sheet metal for commercial air conditioning units. 【Sheet Metal Products】 ■ Prototype Parts for Commercial Air Conditioners - Size: 800×600×500 - Material: SGCC - Plate Thickness: 1.2mm - Lot: 5 pieces (prototype) - Delivery Time: 6 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenco, we manufacture automotive prototype sheet metal that achieves high precision, short delivery times, and a variety of products. From 3D laser processing to handmade items, we propose prototypes tailored to our customers' needs. We would like to introduce examples of our prototype mold processing products, focusing on prototype sheet metal processing. 【Prototype Mold Processing Products】 ■ Prototype Mold Processing (ZAS Type) - Size: 1800×600×500 - Material: ZAS - Plate Thickness: 1.6mm - Lot: Single item (2 processes, concave and convex processing) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenco, we manufacture automotive prototype sheet metal that achieves high precision, short delivery times, and a variety of products. From 3D laser processing to handcrafted items, we propose prototypes tailored to our customers' needs. We would like to introduce a case study of our prototype mold processed products, focusing on metal processing for prototype sheet metal: "Prototype Parts for Agricultural Machinery." 【Prototype Mold Processed Products】 ■ Prototype Parts for Agricultural Machinery - Size: 1200×600×600 - Material: SPCE - Plate Thickness: 1.6mm - Lot: 10 pieces *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Hayano Kenco, we manufacture automotive prototype sheet metal that achieves high precision, short delivery times, and a variety of products. From 3D laser processing to handmade solutions, we propose prototypes tailored to our customers' needs. We would like to introduce examples of our prototype mold processed products, focusing on metal processing for automotive prototype parts. 【Prototype Mold Processed Products】 ■ Automotive Prototype Parts - Size: 400×300×50 - Material: JSC 270C - Plate Thickness: 2.6–3.2mm - Lot: Prototype to 20 - Delivery Time: 20 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Electrolytic corrosion is a phenomenon that promotes rust and significantly impairs durability. When assembling different metals, it is important to be cautious of electrolytic corrosion. If no countermeasures are taken, rust will occur on the contact surfaces more quickly than usual, and the greater the potential difference between the different metals, the more likely electrolytic corrosion is to be promoted. In the assembly of sheet metal, typical combinations include "aluminum + iron," "aluminum + stainless steel," and "iron + aluminum." Applying paint or surface treatment to the materials is one common and cost-effective countermeasure. 【Countermeasures】 ■ Insert insulating material at the contact points ■ Apply paint or surface treatment to the materials ■ Change to a non-conductive material *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

If there is a hole processing at the bending edge, it is best to shift the hole arrangement due to concerns about deformation. However, if you absolutely want to maintain the arrangement, additional hole processing is performed with a drill or similar tool after bending, which leads to quality issues and increased costs. By adding a 'relief hole' at the bending edge, bending stress can be alleviated. Furthermore, by reducing the impact of stress, it becomes possible to prevent deformation of the necessary round holes and reduce processing man-hours. 【Features】 ■ Addition of 'relief holes' at the bending edge ■ Ability to relieve bending stress ■ Prevention of round hole deformation ■ Reduction of processing man-hours ■ Possible improvement in quality and reduction in costs *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When designing punching components, designers independently consider hole diameters and punching patterns to reflect them in the product. If you are particular about originality, there is no problem, but it can lead to increased costs. Therefore, if there are no functional issues, it is necessary to consider standard patterns and hole diameters. Specialized manufacturers possess multi-hole punching molds, so when adopting punching metal, even if it is an original product, aligning the punching pattern with the standards can potentially reduce costs. [Features] - Possession of multi-hole punching molds - Aligning punching patterns with standards *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

After laser processing, drilling is performed. Due to the manual work with the drill press, there is a possibility of unprocessed defects and issues with processing height. The variability in processing can be significant among operators, leading to unstable quality, and it requires management of the drill bit tips, height, and depth, which can be cumbersome. By adopting features such as countersunk holes and rivet holes that can be formed using a composite machine mold, a significant improvement in quality can be expected. Furthermore, since the forming is also done through press processing, variability can be minimized. [Features] - Adoption of countersunk holes and rivet holes that can be formed using a composite machine mold - Significant improvement in quality - Variability can also be minimized *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When performing welding on sheet metal, if the material is prone to distortion and the thickness of the sheet is less than 1.5mm, TIG welding requires a high level of welding skill, and distortion due to heat becomes significant, which may lead to holes being created by the welding in some situations. As a countermeasure, unless thinness is necessary in the design, welding areas should be designed with a thickness of 1.5mm or more to avoid distortion and hole formation. If welding of thin sheets is absolutely necessary, it is advisable to refrain from full circumferential welding and switch to pitch welding or adopt YAG welding. [Features] - Design welding areas with a thickness of 1.5mm or more unless thinness is required. - Avoid distortion and hole formation. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When performing sheet metal processing, using U-shaped MAG welding can cause distortion on the backside due to heat, resulting in bulging on the surface. For sheet metal products that prioritize appearance, this method not only requires considerable welding effort but also compromises the aesthetic quality. By using bending instead of U-shaped processing and applying spot welding, it is possible to secure a certain level of strength while reducing the welding effort. Furthermore, it can also reduce heat-induced distortion, such as bulging from the welding before improvement, allowing for a cleaner finish. 【Features】 ■ Spot welding ■ Can secure a certain level of strength ■ Reduction of welding effort ■ Reduction of heat-induced distortion *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In product design such as covers, the mounting to the base or bracket of the main body and the appearance quality are important. If the design intent is not indicated on the drawings, the processing may simply be done to fit, resulting in machining that exceeds the diameter of the countersunk screw, making it prone to dirt accumulation and negatively affecting the appearance. By specifying hole processing that adapts to the shape of bolts or screws to be mounted on the main body in the drawings, the appearance quality can be improved, and awareness can be raised on the manufacturing side. Furthermore, this also enhances design aesthetics and prevents dirt accumulation at the mounting points. 【Features】 ■Improved appearance quality by properly indicating hole processing for countersunk screws ■Raises awareness on the manufacturing side ■Enhances design aesthetics and prevents dirt accumulation at the mounting points *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In cases where there is no product fixation and no clamping during processing, the accuracy of the screws varies depending on the skill level of the operator, leading to 'variability.' Additionally, due to the cutting tap processing with a hand tapper, it can cause the generation of chips and thread burrs. By specifying machine processing with a rolling tap in the drawings, the generation of tap chips and thread burrs can be reduced. Clamping allows for high positioning accuracy, making it possible to eliminate screw accuracy defects. Using a rolling tap (tap formed by plastic deformation) on a composite machine enables cost reduction. 【Features】 ■ Adoption of rolling taps (taps formed by plastic deformation) ■ Reduction of tap chips and thread burrs ■ Clamping allows for high positioning accuracy, making it possible to eliminate screw accuracy defects *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In sheet metal products made up of multiple parts, factors such as ease of assembly, ease of positioning, and the necessity of jigs greatly affect costs. If there is no positioning 'tab' at the joint of the parts, it can lead to misalignment during welding or when aligning the parts, resulting in poor workability. By providing a positioning 'tab' at the joint of the parts, misalignment during assembly is prevented, and workability during combination is improved. If the parts are accurately manufactured, the need for jigs is eliminated, enhancing assembly efficiency and enabling cost reduction. 【Features】 ■ Provision of positioning 'tabs' ■ Prevention of misalignment and improved workability ■ Elimination of the need for jigs if parts are accurate ■ Improved assembly efficiency *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

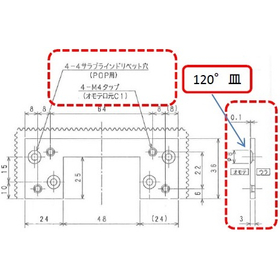

At the individual part drawing level, the front and back are not clearly defined, and it is unclear which rivet specifications to use, so it is necessary to refer to the SUB/ASSY drawing. As a result, this is time-consuming, and since the angle of the dish is not clearly specified, it becomes easy to make processing mistakes. When creating individual part drawings, it is important to clearly indicate the front and back of the product, as well as to include dimension details and the manufacturer to ensure that the drawings can be processed without referring to the ASSY drawings. This will result in individual part drawings that clearly indicate their intended use. By specifying details, we can reduce processing defects, prevent assembly troubles, and contribute to cost reduction. [Features] - By understanding processing details, the individual part drawing will indicate its intended use. - Eliminates the need to refer to ASSY drawings. - By specifying details, processing defects are reduced, and assembly troubles are prevented. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Using dedicated press molds for drawing allows for processing with a very high dimensional accuracy of ±0.05. However, in sheet metal products that undergo drawing processing, not everything needs to be processed with high precision. If a new press mold is created each time, costs will increase, and it may also result in excessive quality in terms of dimensional accuracy. The simple positioning method using a simple mold, "simple mold," is a cost-effective approach for initial investment. Designing according to this dimensional accuracy helps reduce costs. If dimensional accuracy can be tolerated up to the normal tolerance of ±0.2mm for precision sheet metal, the adoption of simple molds becomes possible, enabling cost reduction. 【Features】 ■ Use of cost-effective simple molds for initial investment ■ Cost reduction by designing according to dimensional accuracy *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When aligning the positions of the main body and parts, if the alignment work between parts occurs frequently during assembly, simply marking is insufficient. As the number of parts to be assembled increases, the time spent on marking itself also increases, and additional time is required for aligning with the marking lines, which may lead to variations in quality depending on the worker. Therefore, to reduce costs, it is necessary to adopt methods that can reduce assembly labor in addition to cutting, bending, and welding. For example, when the workpiece is large during assembly, instead of using marking for positioning, utilizing half-shear (dowel) flat positions allows for high-precision positioning. 【Features】 ■ Utilization of half-shear (dowel) flat positions ■ Enables high-precision positioning ■ Allows for positioning without taking extra time during assembly *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When designing, understanding the processing methods and considering how to realize the specifications indicated in the drawings can lead to cost reduction. Processing C0.2 on the thickness of sheet metal parts is labor-intensive. By specifying C0.3 in the drawings, the processing side will consider how to carry out the C0.3 processing and calculate costs. If there are no issues with tolerances, significant cost reductions can be achieved with descriptions such as "edge chamfer" or "sufficient chamfering to avoid injury." [Features] ■ Edge chamfer ■ Sufficient chamfering to avoid injury *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

For parts that are based on press processing, 3D data is often provided, and products with many freeform surfaces are sent as surface data. If there are no indications in the thickness direction and only surface data is provided, it requires additional work to confirm the instructions in drawings, and there are frequent occurrences of mistakes in instructions or misinterpretations by the manufacturing side. By indicating the thickness direction with a line within the product data in advance, it eliminates the need for confirmation during assembly on the design side, reduces the effort of verification work, achieves cost reduction, and leads to improved quality. When designing, clearly establishing the thickness standards can reduce mistakes in thickness consideration during assembly. 【Features】 ■ Indicates the thickness direction with a line ■ Reduces the need for confirmation and verification work during assembly on the design side ■ Achieves cost reduction and improves quality *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

During processing, since the tap diameter is different, it is necessary to change tools or use a different drill press, which leads to setup changes and increases costs. When designing, it is important to understand the processing methods and to design in a way that minimizes these setup changes. If assembly considerations are also taken into account, it becomes possible to provide products with stable quality. By standardizing the tap diameter during the assembly of the product itself, the tools used during assembly can be unified, and the same screws can be used, which can lead to overall cost reductions. 【Features】 ■ Reduction of setup changes for drilling operations by standardizing tap diameters ■ Improved workability during assembly ■ Reduction of parts management costs *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In products such as covers, the installation on the main body and design (appearance) become important, and interference with the counterpart product may occur, necessitating additional processing. For items like pan head screws, if there is no relief machining at the installation part, it may not be possible to fasten them, which can easily lead to trouble. However, by being aware of the installation parts such as the main body base or brackets, it is possible to prevent issues before they arise. When designing thin plate products like covers, it is essential to check the shape of the base or brackets at the installation parts and to design with an awareness of potential interference, which can help reduce the occurrence of troubles and additional processing costs. [Features] - Reduces the occurrence of troubles and additional processing costs. - Cost reduction can be achieved by being mindful of relief machining. - C1 additional processing for relief. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration