1~31 item / All 31 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~31 item / All 31 items

Filter by category

Our company offers a wide range of "high-performance demagnetization devices" guaranteed to have a demagnetization capability of 5 Gauss (0.5 millitesla) or less. We have various models, including the "damping-type demagnetizer," which is effective for demagnetizing bearing steel and high-carbon steel, as well as "round-type adjustable demagnetizers" and "core-type opposing pole demagnetization devices." We can also customize according to your needs and accommodate made-to-order requests. 【Product Example: Conveyor Up/Down Type Damping Demagnetization Device】 ■ Power Supply Voltage: AC200V 2P 50Hz ■ Operating Voltage: DC24V ■ Control Method: Sequencer Control ■ Up/Down Demagnetization Current: 50A–70A ■ Demagnetization Time: Up Demagnetization 2 seconds OFF 1 second Down Demagnetization 2 seconds ■ Demagnetization Capability: 5 Gauss or less ■ Target Workpieces: Outer Diameter φ100–400mm Width 20–200mm ■ Device External Dimensions: W1400×D800×H2050mm *For more details, please refer to the materials. Feel free to contact us with any inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This catalog is a comprehensive catalog from Kyodo Electromagnetic Industry, a specialized manufacturer with a history and track record in the production of electromagnetic devices, founded in 1969 (Showa 44). It features a wide range of products, including the "electromagnetic chuck," which provides stable adhesion and eliminates thermal distortion, as well as "demagnetizers and devices" and "induction heating devices." Our company supports you with three concepts: "consistent eco-friendly and energy-saving technology," "custom-made and customized solutions," and "comprehensive support and aftercare." Please feel free to contact us when you need assistance. [Contents (excerpt)] ■ Electromagnetic Chucks ■ Demagnetizers and Devices ■ Induction Heating Devices ■ Company Overview ■ Products for Sale <Examples> *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company offers electromagnetic chucks that provide stable and well-balanced adhesion without thermal distortion. We aim to achieve maximum effectiveness with minimal investment. If you are experiencing issues with the functionality of your current electromagnetic chuck (regardless of the manufacturer) due to coil defects, please feel free to contact us. We accept repairs with a short turnaround time, and if requested, we can also reduce thermal distortion and enhance adhesion strength. 【Features】 ■ Stable adhesion strength ■ Elimination of thermal distortion ■ Compatible with small items ■ High-precision grinding support *For more details, please download the materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures "low-frequency induction heating devices" that use low frequencies ranging from 0.2 to 1 kHz. Through the synergistic effect of magnetic induction and eddy currents, it is possible to heat materials from deep within with low capacity. This leads to cost reduction due to high energy efficiency and low power consumption. *In addition to shrink fitting of shafts and bearings, it is also useful for drying and preheating metal parts, etc. We are currently offering a document that includes "Basic Knowledge of Low-Frequency Induction Heating." It introduces the benefits of replacing electric and gas furnaces, as well as examples of applications. [Contents] ■ What is low-frequency induction heating? ■ Features of low-frequency induction heating ■ Differences from electric and gas furnaces ■ Examples of applications for low-frequency induction heating *For more details, please refer to the document. Feel free to contact us with any inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The ultra-low frequency induction heating device 'IMT-30K type (table type)', which replaces electric and gas furnaces, has a shorter heating time and lower power consumption compared to high-frequency induction heating, providing significant economic benefits. The electric consumption capacity is about 1/3 to 1/4 compared to high-frequency induction heating and electric furnaces, achieving cost reduction! We look forward to your inquiries regarding various induction heating applications. 〇 Applications: Preheating, drying, shrink fitting, etc. Example) Preheating of molds Benefits: Longer lifespan of molds, reduction in the number of waste shots, etc. (such as die casting) 【Features】 ■ Heats deep areas with low capacity through the synergistic effect of magnetic induction and eddy currents (electron collisions). ■ Compatible with all metals including iron, copper, cast iron, brass, aluminum, and stainless steel. ■ Extremely effective for the aforementioned shrink fitting and annealing. ■ More economical with shorter heating cycles compared to radiant heat from electric and gas furnaces. ■ Can be installed in a compact space. ■ Reduction in power consumption (ultra-low frequency is defined as 0.2 KHz to 1 KHz or lower). *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

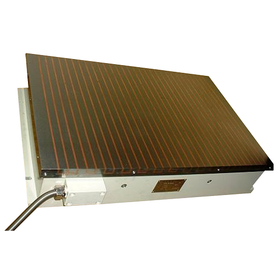

The "RSC-250-8S" is an electromagnetic chuck manufactured by Kyodo Electromagnetic Industry Co., Ltd., which produces low-frequency induction heating devices, demagnetizers, and more. Our company manufactures and provides electromagnetic chucks that offer stable and well-balanced suction without thermal distortion. For customers with new projects, we can design and manufacture electromagnetic chucks to meet any needs, so please feel free to consult with us. 【Features】 ■ Stable and well-balanced suction ■ No thermal distortion ■ Consistent eco-friendly and energy-saving technology ■ Customizable and made-to-order ■ Comprehensive support and aftercare *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SMC-750D" is a round electromagnetic chuck with fine details manufactured by Kyodo Electromagnetic Industry Co., Ltd., which produces low-frequency induction heating devices and demagnetizers. Our company manufactures and provides electromagnetic chucks that offer stable and well-balanced suction without thermal distortion. For customers with new projects, we can design and manufacture electromagnetic chucks to meet any needs, so please feel free to consult with us. 【Features】 ■ Stable and well-balanced suction ■ No thermal distortion ■ Consistent eco-friendly and energy-saving technology ■ Customizable and made-to-order ■ Comprehensive support and aftercare *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "AMC-154DS" is a round electromagnetic chuck manufactured by Kyodo Electromagnetic Industry Co., Ltd., which produces low-frequency induction heating devices, demagnetizers, and more. Our company manufactures and provides electromagnetic chucks that offer stable and well-balanced suction without thermal distortion. For customers with new projects, we can design and manufacture electromagnetic chucks to meet any needs, so please feel free to consult with us. 【Features】 ■ Coil-fixed type ■ Stable and well-balanced suction ■ No thermal distortion ■ Consistent eco-friendly and energy-saving technology ■ Custom-made and customizable *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "AMC-11×100" is a bipolar rectangular electromagnetic chuck for precision grinding on linear rails, manufactured by Kyodo Electromagnetic Industry Co., Ltd., which produces low-frequency induction heating devices, demagnetizers, and more. Our company manufactures and provides electromagnetic chucks that offer stable and well-balanced adhesion without thermal distortion. For new customers with plans, we can design and manufacture electromagnetic chucks to meet any needs, so please feel free to consult with us. 【Features】 ■ For precision grinding on linear rails ■ Stable and well-balanced adhesion ■ No thermal distortion ■ Consistent eco-friendly and energy-saving technology ■ Customizable and made-to-order *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "AMC-40×60" is a rectangular electromagnetic chuck for precision grinding machines, manufactured by Kyodo Electromagnetic Industry Co., Ltd., which produces low-frequency induction heating devices and demagnetizers. Our company manufactures and provides electromagnetic chucks that offer stable and well-balanced adhesion without thermal distortion. For customers with new projects, we can design and manufacture electromagnetic chucks to meet any needs, so please feel free to consult with us. 【Features】 ■ For precision grinding machines ■ Stable and well-balanced adhesion ■ No thermal distortion ■ Consistent eco-friendly and energy-saving technology ■ Custom-made and customizable *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "VAMT-350C" is a V-type adjustable demagnetization device. Our "demagnetizer" solves issues such as residual magnetism after using magnetic chucks. If you are struggling with demagnetization or think it might be difficult, please feel free to consult us. 【Features】 ■ V-type adjustable ■ Integrated control ■ Target workpieces - Rollers for bearings and hardened shaft components - Demagnetization of camshaft ring-shaped components ■ Solves problems related to residual magnetism after using magnetic chucks *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "TMT-130×60" is a core-type demagnetizing device. Our "demagnetizer" solves issues such as residual magnetism after using magnetic chucks. If you are struggling with demagnetization, please consult us before assuming it is difficult. 【Features】 ■ Core-type opposing pole design ■ Equipped with a fixed distribution function ■ Resolves issues of residual magnetism after using magnetic chucks *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The RMT-175 is a round-type demagnetizer (head only). Our "demagnetizer" solves issues such as residual magnetism after using magnetic chucks. If you are struggling with demagnetization, please consult us before assuming it is difficult. 【Features】 ■ Round-type (head only) ■ Separate control panel for fixed distribution ■ Solves issues related to residual magnetism after using magnetic chucks *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "RMT-250F" is a round-type demagnetizer with an aluminum frame. Our "demagnetizer" solves issues such as residual magnetism after using magnetic chucks. If you are having trouble with demagnetization, please consult us before assuming it is difficult. 【Features】 ■ Round-type adjustable (with aluminum frame) ■ Separate control panel for fixed distribution ■ Solves issues of residual magnetism after using magnetic chucks *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "RMT-250TS" is a round-type demagnetizer. Our "demagnetizer" solves issues such as residual magnetism after using magnetic chucks. If you are struggling with demagnetization, please consult us before assuming it is difficult. 【Features】 ■ Round-type adjustment ■ Separate control panel for fixed distribution ■ Solves issues such as residual magnetism after using magnetic chucks *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "VAMT-1300RL" is a V-type adjustable demagnetizing device. Our "demagnetizer" solves issues such as residual magnetism after using magnetic chucks. If you are struggling with demagnetization, please consult us before assuming it is difficult. 【Features】 ■ V-type adjustable ■ Vertical roll included ■ Solves issues of residual magnetism after using magnetic chucks *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "CMT-420×250-2M" is a demagnetizing device with a conveyor-type vertical damping system. It boasts high performance while remaining stationary and is particularly effective for demagnetizing bearing steel and high carbon steel. Our "demagnetizer" addresses issues such as residual magnetism after using magnetic chucks. If you are struggling with magnetism issues, please consult us before assuming it is too difficult. 【Features】 ■ Conveyor-type vertical damping system ■ High performance ■ Effective for demagnetizing bearing steel and high carbon steel ■ Solves problems related to residual magnetism after using magnetic chucks *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "CMT-220×150" is a conveyor-type demagnetizing device. Our "demagnetizer" solves issues such as residual magnetism after using magnetic chucking. If you are struggling with demagnetization, please consult us before assuming it is difficult. 【Features】 ■ Conveyor type ■ Demagnetization at the center of the conveyor for attenuation ■ Target workpieces: Parts for hub bearings with shafts ■ Solves issues of residual magnetism after using magnetic chucking *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IHH-40-CN" is a water-cooled low-frequency induction heating device that automatically shrinks the stator onto AC workpieces heated by an indexing method. Our "low-frequency induction heating device" uses a frequency range of ultra-low frequencies from 0.2 kHz to 1 kHz, and through the synergistic effect of magnetic induction and eddy currents (electron collisions), it can heat materials from deep within with low capacity. The heated objects can include all metals such as iron, steel, copper, brass, cast iron, aluminum, and stainless steel. 【Features】 ■ Induction heating coil with a lifting mechanism ■ Uses water-cooled coils (cooling is done by a unit cooler) ■ Shorter heating time compared to electric and gas furnaces ■ Low power consumption and economical ■ Compact *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IHH-37KW" is a water-cooled induction heating device. Our "low-frequency induction heating device" operates within a frequency range of ultra-low frequencies from 0.2KHz to 1KHz. It is capable of heating materials from deep within due to the synergistic effect of magnetic induction and eddy currents (electron collisions), all while maintaining a low capacity. The heated objects can include all metals such as iron, steel, copper, brass, cast iron, aluminum, stainless steel, and more. 【Features】 ■ Water-cooled ■ Air source of 0.3Mpa or higher ■ Shorter heating time compared to electric and gas furnaces ■ Low power consumption, making it economical ■ Compact *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Compared to high-frequency induction heating, the heating time is shorter, power consumption is lower, and there are significant economic benefits. The electricity consumption capacity is about 1/3 to 1/4 that of high-frequency induction heating and electric furnaces, achieving cost reduction! The "MIHI-130-3P" is a water-cooled low-frequency induction heating device for AC component heating and painting equipment. Our "low-frequency induction heating device" uses a frequency range of ultra-low frequencies from 0.2 kHz to 1 kHz, and through the synergistic effect of magnetic induction and eddy currents (electron collisions), it can heat materials from deep within with low capacity. The heated objects can include all metals such as iron, steel, copper, brass, cast iron, aluminum, stainless steel, and more. 【Features】 - For AC component heating and painting equipment - Uses water-cooled coils (cooling is dependent on a unit cooler) - Shorter heating time compared to electric furnaces and gas furnaces - Lower power consumption and economical - Compact *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Compared to high-frequency induction heating, the heating time is shorter, power consumption is lower, and there are significant economic benefits. The power consumption capacity is about 1/3 to 1/4 that of high-frequency induction heating and electric furnaces, achieving cost reduction! The "IHC-200MT-AD" is an air-cooled low-frequency induction heating machine (elevating type for bogie heating) for extracting the front ring of wheel axles. Our "low-frequency induction heating device" uses a frequency range of ultra-low frequencies from 0.2 kHz to 1 kHz, and through the synergistic effect of magnetic induction and eddy currents (electron collisions), it can heat materials from deep within with low capacity. The items to be heated can include all metals such as iron, steel, copper, brass, cast iron, aluminum, stainless steel, and more. 【Features】 ■ Manual extraction function for housing and sleeve ■ Separate oscillation control panel included ■ Shorter heating time compared to electric and gas furnaces ■ Low power consumption and economical ■ Compact *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IHM-300-1P-600S" is an automatic lift water-cooled induction heating device for heating stator casings. Our "low-frequency induction heating device" utilizes a frequency range of ultra-low frequencies from 0.2 kHz to 1 kHz, and through the synergistic effect of magnetic induction and eddy currents (electron collisions), it is capable of heating materials from deep within with low capacity. The heated objects can include all metals such as iron, steel, copper, brass, cast iron, aluminum, stainless steel, and more. 【Features】 - For heating stator casings - Shorter heating time compared to electric and gas furnaces - Economical with low power consumption - Compact *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Compared to high-frequency induction heating, the heating time is shorter, power consumption is lower, and there are significant economic benefits. The electricity consumption capacity is about 1/3 to 1/4 of that of high-frequency induction heating and electric furnaces, achieving cost reduction! The "IHI-140B-D" is a water-cooled low-frequency induction heating device for shrink fitting angular bearings. Our "low-frequency induction heating device" uses a frequency range of ultra-low frequency 0.2 kHz to 1 kHz, and through the synergistic effect of magnetic induction and eddy currents (electron collisions), it can heat materials from deep within at low capacity. The heated objects can include all metals such as iron, steel, copper, brass, cast iron, aluminum, and stainless steel. 【Features】 ■ For shrink fitting angular bearings ■ Touch panel operation ■ Shorter heating time compared to electric and gas furnaces ■ Economical with low power consumption ■ Compact *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IHL-1PH-M" is a water-cooled low-frequency induction heating device for rotor shaft shrink fitting. Our "low-frequency induction heating device" operates within a frequency range of ultra-low frequencies from 0.2 kHz to 1 kHz, utilizing the synergistic effect of magnetic induction and eddy currents (electron collisions) to heat materials from deep within with low capacity. The heated objects can include all metals such as iron, steel, copper, brass, cast iron, aluminum, stainless steel, and more. 【Features】 ■ For rotor shaft shrink fitting ■ Equipped with a workpiece pressing infrared radiation temperature sensor ■ Shorter heating time compared to electric and gas furnaces ■ Low power consumption and economical ■ Compact *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IHH-37KW" is a water-cooled induction heating device. Our "low-frequency induction heating device" uses a frequency range of ultra-low frequencies from 0.2KHz to 1KHz, and through the synergistic effect of magnetic induction and eddy currents (electron collisions), it is capable of heating materials from deep within with low capacity. The heated objects can include all metals such as iron, steel, copper, brass, cast iron, aluminum, stainless steel, and more. 【Features】 ■ Water-cooled ■ Air source of 0.3Mpa or more ■ Shorter heating time compared to electric and gas furnaces ■ Low power consumption, economical ■ Compact *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IHD-55K-45M" is an induction heating device for gear side bearing components used in gear units. Our "low-frequency induction heating device" utilizes a frequency range of ultra-low frequencies from 0.2 kHz to 1 kHz. It is a device that can heat materials from deep within due to the synergistic effect of magnetic induction and eddy currents (electron collisions), while maintaining a low capacity. The items to be heated can include all metals such as iron, steel, copper, brass, cast iron, aluminum, stainless steel, and more. 【Features】 ■ For gear units ■ Equipped with a lifting function for the lower heating section's iron core ■ Shorter heating time compared to electric and gas furnaces ■ Economical with low power consumption ■ Compact *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"IHEM-2PHS" is a double-position water-cooled electromagnetic induction heating device. Our "low-frequency induction heating device" operates within a frequency range of ultra-low frequencies from 0.2 kHz to 1 kHz, utilizing the synergistic effect of magnetic induction and eddy currents (electron collisions) to heat materials from deep within with low capacity. The heated materials can include all metals such as iron, steel, copper, brass, cast iron, aluminum, and stainless steel. [Features] ■ Double-position type ■ Shorter heating time compared to electric and gas furnaces ■ Low power consumption, economical ■ Compact *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IHT-600KDN" is a water-cooled electromagnetic induction heating device for bearing shrink fitting. Our "low-frequency induction heating device" utilizes a frequency range of ultra-low frequencies from 0.2KHz to 1KHz. It is a device that can heat materials from deep within due to the synergistic effect of magnetic induction and eddy currents (electron collisions), while maintaining a low capacity. The heated objects can include all metals such as iron, steel, copper, brass, cast iron, aluminum, stainless steel, and more. 【Features】 ■ For bearing shrink fitting ■ Sequencer system ■ Shorter heating time compared to electric and gas furnaces ■ Low power consumption, economical ■ Compact *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "RSC-400-8S" is an electromagnetic chuck manufactured by Kyodo Electromagnetic Industry Co., Ltd., which produces low-frequency induction heating devices and demagnetizers. Our company manufactures and provides electromagnetic chucks that offer stable and well-balanced adhesion without thermal distortion. We cater to all kinds of needs for new projects, so please feel free to consult us for the design and production of electromagnetic chucks. 【Features】 ■ Stable and well-balanced adhesion ■ No thermal distortion ■ Consistent eco-friendly and energy-saving technology ■ Customizable and made-to-order ■ Comprehensive support and aftercare *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our demagnetizers boast high performance while remaining stationary, effectively demagnetizing bearing steel and high carbon steel. In particular, our demagnetizing devices, guaranteed to have a demagnetizing capacity of 0.5 millitesla or less, have garnered attention from OA manufacturers and bearing manufacturers in the precision machinery parts sector, and have received high praise from our customers. 【Main Products】 ■ Conveyor-type upper and lower damping demagnetizer ■ Conveyor-type demagnetizer ■ Upper and lower conveyor damping demagnetizer ■ V-type adjustable demagnetizer ■ Round-type adjustable demagnetizer, etc. *For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration