1~39 item / All 39 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~39 item / All 39 items

Filter by category

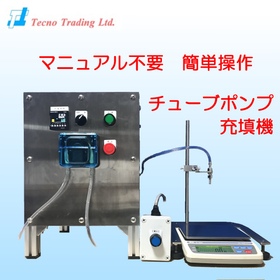

The weight management tube pump filling machine is a device that enables flexible operation based on small-lot, diverse production. Setting filling conditions is simple, and the design minimizes dependence on the skills and experience of the operator. It is suitable for the subdividing process of daily necessities and cosmetics, and can be customized to fit production content and on-site environments. 【Features】 ■ Only the tube comes into contact with the contents ■ Smooth variety changes ■ Intuitive condition settings ■ Stable filling with weight management method ■ Easy adjustment of filling amounts ■ Improved efficiency in startup operations *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This device adopts a design that achieves stable filling through a weight management method while minimizing the effort required for cleaning and changeovers. Since the contact part consists only of tubes, the cleaning process during product changes can be kept to a minimum. It is suitable for small-lot production of various items such as daily necessities and cosmetics, and it performs well in environments that prioritize work efficiency. Customization options such as specification changes and additional features are also available. 【Features】 ■ Contact part has a tube structure ■ Reduces the workload during product changes ■ Simple one-touch operation for settings ■ Weight control that does not require drop correction ■ Smooth adjustment of filling quantity ■ Labor-saving preparation for work *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The tube pump filling device that adopts a weight management method features ease of use, allowing for intuitive adjustment of filling amounts and setting of conditions. It was developed with the aim of enabling setup and work commencement in a short time, even without specialized knowledge or concerns about the display language. It is ideal for small packaging tasks where the types of products, such as daily necessities and cosmetics, frequently change. It also flexibly accommodates customization according to applications and operations. 【Features】 ■ Only the tube comes into contact with the liquid ■ Easy switching operations reduce setup time ■ Condition settings can be done with one touch ■ No need for drop height adjustments ■ Fine-tuning of filling amounts is easy ■ Reduces the burden of startup preparation *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Weight Management Tube Pump Filling Machine" is a product that allows for easy setting of filling amounts without the hassle. With the concept of a filling machine that can be set and operated "even without knowledge," "even without being able to read Japanese," "easily," and "in a short time," we have developed this device. It is suitable for small-scale packaging tasks of various everyday items and cosmetics. Additionally, it can be customized according to your requests. 【Features】 ■ Only the tube is in contact with the liquid ■ Easy to change product types ■ One-touch condition setting ■ No need for drop correction ■ Easy adjustment of filling amounts ■ Simple preparation for starting filling operations *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company imports, manufactures, and sells various types of filling machines. Additionally, leveraging our extensive know-how in process improvement and our network of specialized manufacturers of labor-saving equipment centered around filling machines, we provide suitable solutions to our customers' process challenges and make proposals. Please feel free to consult us when needed. 【Business Activities】 ■ Planning of automatic control production lines and labor-saving devices ■ Sales of automatic and semi-automatic filling machines for liquids ■ Sales of pressure-resistant explosion-proof filling machines for hazardous areas ■ Sales of other packaging-related equipment and transportation-related equipment *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kanta Series" is a wide-ranging series that covers small quantities from 100g to 6.0kg, medium quantities from 4kg to 25kg, heavy quantities from 50kg to 250kg, and also includes options for 1-ton containers. For liquid contact parts, in addition to stainless steel (SUS304, SUS316L) and metal valves that cannot accommodate certain chemicals, we also offer resin valves made of Teflon and PVC. We provide basic functions such as quality judgment after filling, refilling, additional filling, and automatic drop correction, as well as options like automatic drip catch devices and filling history (printer or FC writing). 【Features】 ■ A series that covers a wide range including heavy and 1-ton container options ■ Liquid contact parts can also accommodate resin valves made of Teflon and PVC ■ Various options are also available *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product is a semi-automatic weight filling machine with pressure-resistant explosion-proof specifications, capable of handling small quantities of around 1 kg up to filling 1.5-ton containers. It can memorize filling conditions for each product through brand registration, and a data logger can be installed on the side of the control panel. Additionally, it can manage filling history data, and the contact parts such as filling valves and nozzles are made of standard SUS material, with compatibility for resin valves and nozzles. You can choose from three types of filling valves: fixed type, can mouth lift type, and long nozzle type. 【Features】 ■ Pressure-resistant explosion-proof specifications for small quantities of around 1 kg to 1.5-ton container filling ■ Ability to memorize filling conditions for each product through brand registration ■ Data logger installation possible on the side of the control panel ■ Management of filling history data ■ Standard SUS material, compatible with resin valves and nozzles ■ Three selectable types of filling valves *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product can fill solid food items up to approximately 25mm in size, as well as ultra-high viscosity products. Due to the small number of parts, it can be easily disassembled for cleaning. Disassembly and reassembly can be completed in about 5 minutes. 【Features】 ■ Capable of filling solid food items up to approximately 25mm in size ■ Easy to clean due to the small number of parts that can be disassembled ■ Disassembly and reassembly can be completed in about 5 minutes *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer a variety of nozzles designed to efficiently utilize the diameter of containers. These include the "Shower Nozzle," which dispenses low-viscosity liquids like water in a shower-like spray, the "Large Diameter Nozzle," which has wider openings to improve liquid flow, and the "Long Nozzle," which is used for filling foamed products. You can choose from a wide range of nozzles based on the characteristics of the liquid. 【Lineup】 ■ Shower Nozzle ■ Large Diameter Nozzle ■ Long Nozzle ■ Shear Blade and Plunger Valve *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product is a machine that can easily fill a set amount of liquid into various containers. It has a simple structure and can be used for filling from 0.2ml to 500ml. We offer two types: standard and chemical-resistant. We also provide fluororesin valves for acid and alkali-resistant chemicals. 【Features】 ■ Simple structure ■ Easy filling of a set amount of liquid into various containers ■ For filling from 0.2ml to 500ml ■ Two types: standard and chemical-resistant ■ Fluororesin valves for acid and alkali-resistant chemicals are also available *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to the various types of cappers we handle. We offer a range of equipment tailored to customer needs, including fully automatic types linked to filling machines, semi-automatic types with torque control capabilities, and inexpensive simple types. These machines are easy to operate, reducing variability in cap tightening tasks and alleviating the workload for operators. Additionally, we provide pressure-resistant explosion-proof specifications and all-air types for hazardous areas. 【Features】 ■ Easy to operate ■ Reduces variability in cap tightening tasks and the workload for operators ■ We propose equipment that meets your requirements *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Cap Tightening Machine and Plugging Machine" is a capper that can handle pressure-resistant explosion-proof specifications and torque management. We manufacture cappers and plugging machines tailored to container shapes, various types, working environments, and desired capacities. Customization according to application is also possible. Additionally, we offer a cost-effective and simple capper. 【Features】 ■ Can be used in hazardous areas due to pressure-resistant explosion-proof specifications ■ Customization available according to application ■ Also offers cost-effective simple cappers *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "semi-automatic filling machine" is a liquid filling machine manufactured to suit the characteristics of the liquid (viscosity, presence of foaming, pH, specific gravity, etc.), container shape, working environment, and desired capacity. It can be designed to meet pressure-resistant explosion-proof specifications, making it suitable for use in hazardous areas. Additionally, we improve any issues related to work by selecting nozzles, measuring methods, and providing the desired machine with pressure-resistant explosion-proof specifications. If you have any concerns regarding filling machines, please feel free to consult us. 【Features】 ■ Customization according to application is possible ■ Sanitary structure that allows for easy disassembly, assembly, and cleaning ■ Can accommodate pressure-resistant explosion-proof specifications, making it suitable for use in hazardous areas *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Fully Automatic Filling Machine Line" is a liquid filling machine designed to be manufactured according to liquid characteristics (viscosity, presence of foaming, pH, specific gravity, etc.), container shape, working environment, and desired capacity. We improve work-related issues through the selection of nozzles, weighing methods, and pressure-resistant explosion-proof specifications, providing the machinery you need. It is possible to systematize the filling of mass-produced products, cap tightening, plugging, labeling, etc. 【Features】 ■ Can accommodate pressure-resistant explosion-proof specifications, allowing use in hazardous material areas ■ Customization available according to application ■ Sanitary structure that allows for easy disassembly, assembly, and cleaning ■ Dedicated lines can be constructed according to your requirements *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Techno Co., Ltd. handles fully automated and semi-automatic filling machines, accommodating various liquids such as those with high temperatures and high viscosity. We support a wide range of containers, including small containers, one-gallon cans, drum cans, and other irregularly shaped containers. Additionally, we propose nozzles suited to your specific operational needs. Please feel free to contact us regarding any inquiries about filling machines. 【Do you have any of these filling machine concerns?】 - I want to fill a liquid that foams, but it overflows with the existing nozzle. - The nozzle doesn't fit the container, making filling difficult. - I want to manage the supply of empty cans, filling, capping, and collecting filled containers all by myself. - I am looking for a filling machine for hazardous materials. - I want to increase filling capacity. - I want to manage the torque for capping. - I want to make the loading and unloading of drum cans easier. - I want to centralize the process from container supply to filling, capping, and labeling. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Techno Co., Ltd. handles fully automatic, semi-automatic, weight-based, and volume-based filling machines. We offer a wide variety of containers, including small packaging containers, one-gallon cans, and drum cans, suitable for various liquids such as high-temperature and high-viscosity substances. Additionally, we manufacture original nozzles tailored to specific work purposes. Please feel free to contact us regarding any inquiries about filling machines. 【Features】 ■ A wide variety of containers, including small packaging containers, one-gallon cans, and drum cans, compatible with various liquids such as high-temperature and high-viscosity substances. ■ We solve customers' concerns regarding filling without any leaks. ■ A company that shapes customers' requests into reality. *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features It allows for easier cap tightening than manual tightening. Achieves stable torque tightening. Anyone can easily perform the task. Custom solutions are available for irregular caps. The simple cap tightening machine "CAPMATE II" enables easy cap tightening anywhere.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Tabletop Cap Tightening Machine" is a product that allows for one-touch operation by placing the cap and pressing the container against it. Inserts can be exchanged depending on the size of the cap (maximum cap dimension 57mm). The torque can be selected according to the cap and adjusted continuously. Rentals are also available. Please contact us for more information. 【Specifications】 ■ Material Used - Frame: Ordinary steel with a plated finish - Control panel: Ordinary steel with a painted finish ■ Capacity: 10-15 bottles/min ■ Power Supply: AC100V ■ Air Pressure - Air Pressure: 0.4MPa - Usage: 30NL/min *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Kanta" is a pressure-resistant explosion-proof type of heavy-duty semi-automatic liquid filling machine that can be used in hazardous areas up to Exd IIBT4. The materials in contact with the liquid are made of SUS316L and Teflon, which are highly resistant to chemicals, as standard. You can choose optional equipment such as a can mouth lifting device and an automatic drip-catching device to prevent splashing from the can mouth during filling. 【Features】 ■ Can be used for filling in hazardous areas (Exd II BT4) handling chemicals, paints, solvents, and petroleum products ■ The filling valve is made of high-grade SUS316 and Teflon as standard ■ Two types of nozzles are available depending on the liquid: short nozzle and long nozzle (linear) ■ Types available according to the filling operation: 6kg/2g, 15kg/5g, 30kg/10g *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kanta Mini" is a small-capacity filling machine equipped with a high-precision measuring device. The entire unit is made of stainless steel, and the parts that come into contact with the liquid, such as the filling valve and nozzle, are finished in SUS316 sanitary grade. Thanks to the opening adjustment function of the two-stage control filling valve during small filling, it can accommodate a variety of liquid qualities. 【Features】 ■ Suitable for filling small cans, glass bottles, and plastic containers ■ Stainless steel sanitary specifications ■ Available in sheet nozzle and long nozzle specifications ■ Filling valve's up-and-down lifting function (optional) is effective in preventing splashing during filling ■ Automatic drip tray (optional) *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"CAPMATE II" is a compact, lightweight, and economical simple cap tightening machine. The torque can be adjusted continuously, and when the cap is tightened, the torque automatically cuts off and stops. Changing the cap chuck and insert is easy and hassle-free. By attaching a spring balancer to the main body’s hanger, work efficiency is improved. 【Features】 ■ Torque can be adjusted continuously ■ Available in low torque and high torque types ■ Can be used anywhere with AC100V (an air-operated version is also available for hazardous areas) ■ Cap tightening operation is simple ■ Low noise and low vibration *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the key points for handling the 'CAPMATE II - Air Specification' managed by Tekuno. When refueling, add a small amount of turbine oil ISOVG32 to the motor section. It operates simply by pressing the tip of the pit against the screw, as it is a push-start type. In addition, it includes information on pit replacement, torque adjustment methods, product specifications, and parts lists. [Main Contents] ■ Key Handling Points ■ LT Series ■ Hose Balancer (Optional) ■ Specifications ■ Layout Diagram ■ Parts List US-LT40A/B-08・15・21 *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Handle-Type Capper Stand for CAPMATE II" allows you to lower the handle and complete cap tightening with just one touch. Once the cap is tightened, the torque is automatically released. Inserts can be exchanged depending on the size of the cap (maximum cap dimension 57mm). 【Features】 ■ Torque selection according to the cap (infinitely adjustable) ■ Inserts can be exchanged based on the size of the cap ■ Power supply: AC100 V *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a filling machine with a capacity that accommodates low to high viscosity liquids. By selecting the cylinder, it can fill from 10ml to 1 can or drum with single cycle filling or double-acting specified filling. It is controlled entirely by air, allowing it to be used in hazardous areas, and its simple structure ensures excellent durability. 【Features】 ■ The wetted parts are made of stainless steel (SUS 316L) ■ All-air system, suitable for use in hazardous areas ■ Easy operation! Just set the container and press the fill start button ■ Filling amount can be set using the dial counter at the rear ■ Filling accuracy: ±0.25% *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an all-air type Riggs mini filling machine. It can be used in hazardous areas and has a simple structure, making it easy to clean. The rotor section is made of special stainless steel, allowing for filling at temperatures close to 100°C. With a systematized nozzle and shear blade, it enables efficient liquid discharge during filling. 【Features】 ■ Contact parts are made of stainless steel (SUS 316L) ■ All-air type, suitable for use in hazardous areas ■ Ideal for filling food, chemicals, pharmaceuticals, fragrances, cosmetics, and more ■ Easy to set the filling amount using the dial counter at the rear ■ Filling accuracy: ±0.25% *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Weight-type (Load Cell type) Semi-Automatic Filling Machine" is made entirely of stainless steel, and the parts in contact with the liquid, such as the filling nozzle and valve, are made of SUS304, making it suitable for filling food and other products. Since it uses a digital display with a memory function for setting values, it is easy to configure settings such as two-stage switching points to minimize errors due to the set quantity and drop height. In addition, we offer a lineup of products such as "Weight-type (Load Cell type) Fully Automatic Filling" and "Close-type Semi-Automatic Filling Machine," which can be operated by one person for the transportation of empty cans and the filling of cans. 【Features of the Semi-Automatic Filling Machine】 ■ Two types of nozzles: short and long ■ PTFE drip tray can be installed ■ Stainless steel sanitary construction ■ Easy operation with digital display ■ Automatic tare weight elimination function *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "All-in Semi-Automatic Liquid Filling Machine" is an economical and user-friendly product made of stainless steel sanitary construction and equipped with a digital weighing device. By integrating the filling machine, liquid transfer pump, and air source, which are essential during startup, it allows for smooth startup operations during the small-scale transfer from a stationary tank. Additionally, the pump's liquid transfer volume is controlled by an inverter in conjunction with filling control, achieving stable filling accuracy. 【Features】 ■ Stainless steel (SUS316) two-stage control filling valve (adjustable for small filling openings) ■ Available in two types: small can (200g to 6kg) and one-gallon can (5kg to 25kg) ■ Compatible with sheet nozzles and long nozzles, as well as bag-in-box systems ■ Simplifies on-site equipment *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document provides instructions on how to adjust the simple cap tightening machine "CAPMATE II (low torque type)." It offers a detailed explanation of torque adjustment and how to replace the torque adjustment spring, using photographs for clarity. This is a useful guide for when using the product. [Contents] ■ About torque adjustment ■ How to replace the torque adjustment spring *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our "Tabletop Semi-Automatic Cap Tightening Machine" is composed of a simple cap tightening machine, "Cap Mate II," and a semi-automatic lifting device controlled by air. When used in conjunction with the air-operated Cap Mate, it can be used in hazardous areas. 【Usage Instructions (Excerpt)】 1. Start with the power of Cap Mate II in the OFF position. 2. Set the air pressure of this machine to approximately 1 kg/cm² using the regulator valve. 3. Place the container with the cap under the Cap Mate, adjusting the position of the container so that the cap is centered. 4. Remove the container and turn on the switch of this machine, allowing Cap Mate II to descend, then adjust to the appropriate height. 5. The working capacity is 15-25 units per minute. *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The mobile filling machine "KANPAK series" each has different features. The liquid filling machine for drums "KANPAK DRM-L" uses a long nozzle and is primarily designed for filling foaming products. When filling foaming products, the nozzle is inserted into the drum, and the nozzle is squeezed until the opening is below the liquid level, preventing air from being drawn in during filling. This allows for minimizing foaming as much as possible. Our website also provides detailed examples of the hazardous material liquid filling machine "KANPAK-EX." [Examples] ■ Liquid filling machine for drums ■ Liquid filling machine for hazardous materials *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "STDL" is a mobile automatic filling machine with high operability and work precision. Its footprint is very compact at 1,350mm x 1,180mm, allowing for effective use of factory space. It uses a digital display load cell scale, making it easy to set various values such as required weighing values, upper and lower limits, and filling speed switching points. 【Features】 ■ Equipped with all necessary functions for filling, including empty can supply, two-stage filling, cap tightening, and discharge of filled cans. ■ Can be freely moved within the site, allowing for direct filling from product tanks. ■ Compatible with both short and long nozzles, enabling filling of foaming products. ■ Capable of recording up to 10 preset values, making it easy to switch between products for filling. ■ Easy operation due to sequencer control. *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"KANPAK EX" is a product that is primarily designed for filling hazardous materials while maintaining high operational safety and ease of use. Its footprint is very compact, roughly the size of a single pallet. It includes all the necessary functions for supplying empty cans, detecting filling openings, two-stage filling, capping, and discharging filled cans. One operator can handle everything from supplying empty cans to palletizing, making it very efficient. 【Features】 - Allows for free movement within the site, enabling direct filling from the product tank. - Utilizes a digital display load cell scale. - Easy to set various values such as required weight, upper limit, lower limit, and filling speed switching points. - Automatic drop correction function that reads the average value of the previous five cans and the set value, automatically adjusting the drop value for the sixth can. *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "filling machine nozzle" is an important part for improving work efficiency and preventing liquid drips. We offer various nozzles designed to make the most efficient use of the container's diameter. By discharging low-viscosity liquids like water in a shower-like manner, we prevent liquid splatter. Furthermore, by utilizing surface tension in each individual narrow hole, we prevent liquid drips. In addition, we have a lineup that includes the convenient "MAXI valve nozzle" and "long nozzle" for large-diameter containers. 【Product Lineup】 ■ Standard filling nozzle for filling valves ■ MAXI valve nozzle ■ Long nozzle ■ Shear blade and plunger valve *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kanta ex" is a filling machine that can be used in hazardous areas, featuring pressure-resistant explosion-proof weighing instruments and electric air conversion boxes. With brand registration, it is possible to memorize filling conditions for each product. The external buttons on the control panel allow you to call up the necessary values for filling. It is suitable for filling sites of organic solvent-based products such as paints, thinners, and adhesives. 【Features】 ■ A data logger can be installed on the side of the control panel. ■ The liquid contact parts, such as filling valves and nozzles, are made of standard SUS material. ■ Resin valves and nozzles are also available. ■ Filling is achieved with a two-stage control valve, ensuring stable filling accuracy. ■ The filling valve comes in three types: fixed type, can mouth lift type, and long nozzle type. *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our filling machines have features suited for various applications. "Fully automatic filling" can be combined with conveyors and turntables to automate the process from supplying empty containers to filling, capping, and product retrieval. Small cans for paint are automatically supplied from a turntable, filled with paint, and the lids are placed on manually. A device that resembles a conveyor running in reverse serves as the capping machine. In addition to this, our website also introduces simple automatic filling. 【Case Studies (Fully Automatic Filling)】 ■ Automatic supply of small cans for paint from a turntable ■ Automatic supply of 3L cans from a turntable *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce the structure of the air-driven piston-type metering pump "Riggs Series." It consists of the rear air pump section, the central metering cylinder section, and the head rotary valve section. To improve accuracy and reduce liquid depletion, a cut valve and nozzle are attached to the discharge end for use. The wetted parts are made of SUS316L and Teflon, and the rotor of the rotary valve is made of special stainless steel, allowing it to be used without issues even at high temperatures of 100°C without seizing. 【Features】 ■ Improved the suction and discharge single tube of the rotary valve from bolt-fixed to an integrated structure ■ Eliminates sources of contamination, allowing for thorough cleaning ■ Complies with CE (EU member country standards) and FDA (U.S. Food and Drug Administration) standards ■ Easy to finely control the forward (discharge) speed and reverse (suction) speed *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Riggs Model 1000 Series" has a wide opening, allowing it to fill solid food products up to about inch-sized and even ultra-high viscosity products. Due to the small number of parts, it can be easily disassembled for cleaning. Disassembly and reassembly can be completed in about 5 minutes. It is capable of filling food oils, meat sauces, ketchup, jams, concentrated juices, honey, retort foods, paints, sealants, resins, and more. 【Features】 - The wetted parts are made of SUS316L stainless steel. - It can withstand chemical solutions up to 100°C without causing seizure in the rotor section. - With fewer parts and a sanitary structure, disassembly and assembly are very easy. - Product supply is possible from hoppers, floor tanks, or overhead tanks. - It can be used as a filling machine or a metering dispensing device when paired with a cut valve. *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Kanta" is a weight-based filling machine that uses a weighing device. It covers a wide range of series for small quantities from 100g to 6.0kg, medium quantities from 4kg to 25kg, and large quantities from 50kg to 250kg, as well as for 1-ton containers. For liquids that cannot be handled with metal valves, such as chemical solutions, resin valves made of Teflon and PVC are also available. You can choose between standard electrical specifications and hazardous area specifications depending on the usage environment. 【Features】 ■ Available in standard electrical specifications and hazardous area specifications (pressure-resistant explosion-proof type and internal pressure explosion-proof type) ■ The filling valve adopts a vertical two-stage control filling valve, allowing for precise filling ■ Individual nozzles with different diameters can be exchanged for the containers being filled ■ The filling valve and nozzle are designed for easy disassembly and cleaning with a hygienic specification *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We handle the "Weight-Type (Load Cell Type) Semi-Automatic Filling Machine." Since it uses a digital display with a setting value memory function, it is easy to set parameters such as the two-stage switching point to reduce errors due to the set quantity and drop height. The filling machine is available for one-gallon cans using a 30kg scale and for small cans using a 15kg scale. 【Features】 ■ Long nozzle design for foamy liquids ■ Compatible with PTFE drip trays ■ Stainless steel sanitary construction ■ Easy operation with digital display ■ Automatic tare weight elimination function ■ Nozzle automatically closes during power outages *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration