- Publication year : 2023

1~13 item / All 13 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~13 item / All 13 items

Our company specializes in the design and manufacturing of precision plastic molds. We excel in precision molding molds and insert molding molds for automotive parts, camera lens barrel parts, electronic components, mobile phone parts, and we cater to various needs including molds for automated production lines. Please feel free to contact us with your inquiries. 【Products Handled】 ■ Plastic molds for precision parts ■ Plastic molds for composite molded parts ■ Plastic molds for thermosetting resin parts 【Achievement Categories】 ■ Automotive parts ■ Game console parts ■ Terminal parts ■ Medical devices ■ Various small items *ISO 9001:2015 and ISO 14001:2015 certified.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Alpec is conducting prototype molding using its own molding machines. We carry out the initial prototype trial in the presence of the customer at our company. Normally, there may be times when the molding machines are not available due to production constraints, but if you leave it to Alpec, there is no need to adjust the production schedule. We have received positive feedback from customers regarding the shortened submission periods from the manufacturer. Please feel free to contact us when you need our services. 【Features】 ■ Initial prototype trials can be conducted in the presence of the customer at our company ■ No need to adjust the production schedule ■ Positive feedback on shortened submission periods from the manufacturer ■ Specifications: Sodick 40-ton horizontal molding machine

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

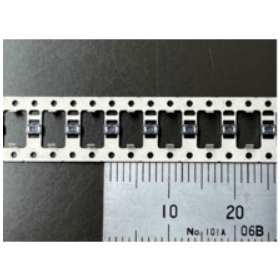

We would like to introduce the design and manufacturing achievements of plastic molds conducted by Alpec. This case involves a fine product with no terminal guiding shape, and the product tolerances are strict. Several companies declined to manufacture the mold, and it came to us through a client referral. In response, we manufactured a high-precision mold based on our track record. The terminal insertion was accommodated by the mold structure. As a result, terminal insertion was smooth, and mass production molding was carried out without any issues. In addition, we have achievements in producing the lid of the above-mentioned component (case) as a set, as well as semiconductor components where we devised the shapes of runners and gates to ensure fluidity. [Summary of Achievements (Partial)] ■ Material: LCP ■ Size: 1.5×2.4×0.5 ■ Application: Electronic components

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the achievements of Arpec in the design and manufacturing of plastic molds. This case involves a micro product with a φ0.3 hole in the slide structure, raising concerns about mold production and durability, as well as gas management due to the use of PEEK. Therefore, we not only installed gas vents but also designed a structure that improves the maintenance of gas contamination, resulting in the production of high-precision molds based on our experience. As a result, we were able to produce good products and carry out mass production molding without any issues. Our company has introduced advanced machining equipment to achieve high-precision processing. Please feel free to contact us when you need our services. 【Overview of Achievements】 ■Material: PEEK ■Size: φ1.8×7.3 ■Application: Medical devices

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the achievements of Arpec in the design and manufacturing of plastic molds. This case involves a micro product with a φ0.3 hole in the slide structure and an M1.4 shape at the tip, raising concerns about mold production and durability. Therefore, we manufactured a high-precision mold based on our experience. As a result, we were able to produce good products and carry out mass production molding without any issues. At our company, we are equipped with prototype molding machines and strive to utilize the knowledge gained from our prototype molding experience in our designs, enabling us to provide molds that can be mass-produced in a short period. Please feel free to contact us when you need our services. 【Overview of Achievements】 ■Material: PC ■Size: φ1.7×5.3(M1.4) ■Application: Medical devices

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the achievements of Arpec in the design and manufacturing of plastic molds. In a case involving a certain PP material, the terminal shape was complex and numerous, making insertion difficult, which resulted in poor production cycles and frequent troubles. To address this, we manufactured a high-precision mold based on our experience and also created jigs to enable stable insertion. We adopted a cassette-type rotary mold specification to improve the cycle. As a result, the terminals became easier to insert, troubles were eliminated, and the production cycle improved. Our company leverages its achievements in the automotive and medical device industries, including "injection molding molds," "hoop molding," and "insert molding" for small precision parts, to meet customer needs. [Summary of Achievements (Partial)] ■ Material: PP ■ Size: 100×80×35 ■ Application: Automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the design and manufacturing achievements of plastic molds conducted by Alpec. In this case, due to the 16-piece two-row hoop, there were concerns about terminal clamping issues and the possibility of burrs since it is made of PPS. Therefore, we manufactured high-precision molds based on our track record. As a result, mass production molding was achieved without any problems. Our company specializes in precision molding molds and insert molds for various applications, including automotive parts, camera lens barrel parts, electronic components, and mobile phone parts, and we respond to various needs such as molds for automated lines. [Overview of Achievements] ■ Material: PPS ■ Size: 14×5×6 ■ Application: Automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the design and manufacturing achievements of plastic molds conducted by Alpec. In this case, the terminal shape was complex and numerous, making insertion difficult, which resulted in poor production cycles and frequent troubles. Therefore, we manufactured a primary molding mold to fix the terminals in two places. We proposed a specification that allows for the simultaneous molding of symmetrical terminals and switching as needed. As a result, although divided into primary and secondary molds, troubles were eliminated and productivity improved. Please feel free to contact us when you need our services. 【Overview of Achievements】 ■Material: PA66 ■Size: 75×38×47 ■Application: Automotive parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the achievements of Arpec in the design and manufacturing of plastic molds. In this case, we were consulted about the need to achieve a dimensional tolerance of ±0.01 mm, as there was a possibility of defects occurring when the product was assembled. Our company specializes in the design and manufacturing of plastic molds and possesses high-precision technology to achieve a dimensional tolerance of ±0.01 mm. As a result, we were able to meet the strict tolerance standards and provide products that meet our customers' requirements. 【Overview of Achievements】 ■ Material: PA46 ■ Size: 13.8×19.8×17.3 ■ Application: Home appliance parts

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the achievements of Arpec in the design and manufacturing of plastic molds. 【Overview of Achievements】 ■Material: PPE ■Size: 11×103.7×6.8

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Alpec, we primarily design and manufacture molds for plastic injection molding of small precision parts, possessing high-precision technology that achieves a dimensional tolerance of ±0.01 mm for our products. We specialize in composite molding molds, such as "hoop molding" and "insert molding," with mold sizes typically ranging from 30 to 130 tons in molding machines. We can also accommodate other sizes upon request. The "Design and Manufacturing Achievements of Plastic Molds" collection includes our production achievements with materials such as LCP, PEEK, PPS, PC, PBT, and PP. Please refer to the related catalogs below. [Included Content (Partial)] ■ LCP (Size: 1.5×2.4×0.5) ■ LCP (Size: 1.5×2.4×0.7) ■ PEEK (Size: φ1.8×7.3) ■ PC (Size: φ1.7×5.3) ■ PBT (Size: 13×8×8)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Do you have any of the following concerns regarding "plastic mold manufacturing"? - The mold's accuracy is poor, resulting in a lot of burrs... - Dimensional accuracy is not achieved, leading to an increased number of corrections and longer time... - The finish of the mold is poor, resulting in frequent breakdowns... Our company solves all of the above issues! We ensure proper alignment and can manufacture molds with minimal burrs. With a machining tolerance of ±0.005 mm, the average number of corrections is about 2, which does not affect the schedule for starting your production. Additionally, with over 50 years of know-how and experience in plastic mold manufacturing, we can produce molds with fewer breakdown issues, which our customers greatly appreciate. We design and manufacture plastic injection molds for small precision parts, possessing high-precision technology that achieves a product dimensional tolerance of ±0.01 mm. We specialize in complex molding molds such as "hoop molding" and "insert molding," with mold sizes typically ranging from 30 to 130 tons for the molding machines. We can also accommodate other sizes based on your requirements. You can download the "Plastic Mold Design and Manufacturing Achievements Collection" from the related catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document is a collection of production achievements by Arpec Co., Ltd. Our company primarily designs and manufactures molds for plastic injection molding of small precision parts. We specialize in composite molding molds, particularly "hoop molding" and "insert molding," with mold sizes typically ranging from 30 to 130 tons based on the molding machine. We have listed our production achievements including LCP, PEEK, PC, PBT, and PP. Please download and view from the related catalog. [Contents (partial)] ■LCP (Size: 1.5×2.4×0.5) ■LCP (Size: 1.5×2.4×0.7) ■PEEK (Size: φ1.8×7.3) ■PC (Size: φ1.7×5.3) ■PBT (Size: 13×8×8)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration