1~13 item / All 13 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~13 item / All 13 items

The explosive welding method is a technique that uses the instantaneous and high energy released when explosives detonate to instantaneously bond metal plates together, thereby producing clad steel plates. BA clad is used for plants and equipment in the chemical industry, petroleum refining, petrochemicals, and power generation, and is exported widely both domestically and internationally, either as flat plates or various components. In addition to being used as corrosion-resistant and heat-resistant structural materials for power plant condenser tube sheets, chemical plant heat exchanger tube sheets, shells, and mirror plates, its applications are expanding endlessly to include rolling mill liners, electrodes, cryogenic joints, ultra-high vacuum joints, and structural joints for ships and LNG tankers.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Asahi Kasei Corporation has developed an explosive bonding technology that utilizes the instantaneous high energy generated during the explosion of explosives to metallurgically join dissimilar metals at room temperature. This product ensures durability by firmly bonding lightweight alloys with high specific strength and specific stiffness, such as flame-retardant magnesium, to materials like aluminum and stainless steel, significantly contributing to the weight reduction of vehicles, ships, and molds. You can also check the bonding samples in your possession. 【Features of Flame-Retardant Magnesium Clad】 ■ Achieves bonding between flame-retardant magnesium, which tends to generate brittle alloy layers and is considered difficult to bond with dissimilar metals, and aluminum and stainless steel (Patent No. 6733049) ■ Realizes weight reduction through composites with lightweight flame-retardant magnesium among practical metals ■ Specific strength superior to titanium and aluminum ■ Serves as a structural dissimilar material joint for bonding magnesium with aluminum and stainless steel *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Asahi Kasei Corporation has a synthesis technology for metal nanoparticles using the combustion energy of explosives. This allows for the possibility of generating nanoparticles that are difficult to produce with conventional synthesis methods, such as composite metals and suboxides of different metals. If you have any wishes for particles you would like to see, please feel free to consult with us. 【Features】 ■ The high temperature and instantaneous reaction characteristic of explosive combustion enables the generation of unique nanoparticles. ■ Capable of accommodating a variety of materials. ■ The elemental ratios of composite metal oxides can be controlled. ■ Synthesis targeting suboxides rather than complete oxides is possible. ■ We possess technology to generate spherical particles. ■ It is also possible to mold and provide powders through processes such as compression. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Asahi Kasei Corporation, we utilize the explosive energy of explosives for the crimping and molding of dissimilar metals, as well as the fabrication of metal components. By using the ultra-high pressure generated from the explosive energy of explosives, we can achieve binderless compaction molding of metal, alloys, and ceramic powders. This allows for increased density and enhanced performance. Additionally, since the compaction using this technology occurs instantaneously, the materials are not exposed to high temperatures for extended periods, making it particularly effective for materials that may deteriorate at high temperatures. 【Features】 - Achieves high density close to the true density of the material as no binder or insert agents are used. - Instantaneous compaction eliminates prolonged thermal load, preventing material degradation due to heat. *These two points allow the inherent properties of the material to be manifested in the molded body. - The shape of the powder before compaction is fundamentally irrelevant. (For shapes where compaction feasibility is uncertain, confirmation will be made through prototyping.) ★【First 10 applicants】 We will provide samples of compacted metal powder. If you are interested, please apply through the "Contact Us" section. ★For more details on what types of powders can be compacted, feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By replacing copper used in materials such as high-current contact materials, electrode materials, and heat exchange materials (heat sinks) with "copper/aluminum clad," we respond to the needs for cost reduction and weight reduction. Additionally, our explosive crimping technology is a cold joining method that does not apply heat to the materials, making it difficult for impurities such as alloy layers to form at the bonding interface between copper and aluminum. This results in low electrical resistance and conductivity close to the theoretical value of the materials. ■ETJ(R) Electrical Transition Joint 【Features】 1. Excellent electrical properties. 2. Superior mechanical properties. High bonding strength, demonstrating robust characteristics in bending and tensile tests. 3. Excellent heat resistance. The bonding strength does not change even after 5,000 cycles of thermal fatigue testing at 250°C and 25°C. 4. Regarding galvanic corrosion: Our clad is fully bonded, preventing electrolytes from penetrating the interface, allowing for protection against galvanic corrosion by painting only the externally exposed surfaces. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Using the ultra-high pressure generated by the explosive energy of explosives, it is possible to manufacture lotus-type metal components. By inserting a small-diameter metal pipe into a large-diameter metal pipe and applying explosive shock compression from the outer circumference, a lotus-type metal component with metallurgically bonded pipes can be obtained. Our lotus-type metal components have excellent thermal conductivity, allowing for compact designs of heat exchange components. Additionally, the material of the piping can be selected according to the usage environment, and the production of dissimilar lotus materials combining different materials is also possible. (Joint research results with Kumamoto University) *For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

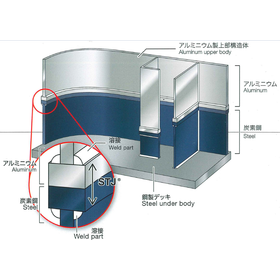

Asahi Kasei Corporation has developed an explosive welding technology that utilizes the instantaneous high energy generated during the explosion of explosives to metallurgically join dissimilar metals at room temperature. This product ensures durability by firmly joining lightweight metals (aluminum, magnesium, titanium) with steel materials, significantly contributing to the weight reduction of vehicles, ships, molds, and more. ■STJ(R) "Structural Transition Joint" STJ(R) is a compact and highly durable structural joint that enables the welded integration of aluminum alloy structures with carbon steel or stainless steel components. ■Flame-retardant Magnesium Alloy Joint A structural joint of flame-retardant magnesium alloy with aluminum alloy or stainless steel. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Asahi Kasei Corporation, we utilize the explosive energy of explosives for the crimping and molding of dissimilar metals, as well as the fabrication of metal components. By using the ultra-high pressure generated from the explosive energy, we can achieve binderless compaction molding of metals, alloys, and ceramic powders. This allows for increased density and enhanced performance. Additionally, since the compaction using this technology occurs instantaneously, the materials are not exposed to high temperatures for extended periods, making it particularly effective for materials that may degrade at high temperatures. For more details on what types of powders can be compacted, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Using the ultra-high pressure generated by the explosive energy of explosives, it is possible to manufacture lotus-type metal components. By inserting a small-diameter metal pipe into a large-diameter metal pipe and applying explosive shock compression from the outer circumference, a lotus-type metal component is obtained where the pipes are metallurgically bonded and integrated. Our lotus-type metal components have excellent thermal conductivity, enabling compact designs for heat exchange devices. Additionally, the material of the piping can be selected according to the usage environment, and it is also possible to produce hybrid lotus materials that combine different materials. (Results of joint research with Kumamoto University) *For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Using the ultra-high pressure generated by the explosive energy of explosives, we can achieve binderless compression molding of metals, alloys, and ceramics. This enables increased density and high performance. Additionally, the compression using this technology occurs instantaneously, so the materials are not exposed to high temperatures for extended periods. This makes it particularly effective for materials that may deteriorate at high temperatures. *For more details, please feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Asahi Kasei Corporation has developed an explosive welding technology that utilizes the instantaneous high energy generated during the explosion of explosives to metallurgically join dissimilar metals in a cold state. This technology enables the strong bonding of aluminum, aluminum alloys, and stainless steel. ■ CCJ(R) "Cryocoup Joint" CCJ(R) is a piping material suitable for extremely low-temperature fluids (such as LNG and liquid nitrogen) that achieves a welded integrated structure between stainless steel pipes and corrosion-resistant aluminum pipes. 【Features】 1. Stainless steel pipes and aluminum pipes can be directly welded through CCJ(R). Compared to flange connections, there is no risk of fluid leakage, making it advantageous for safety. 2. Being boltless, it allows for a smaller outer diameter compared to flanges, enabling a compact design. 3. The bonding strength between dissimilar metals is stable against thermal cycles, with minimal reduction in strength. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By replacing copper used in materials such as high current contact materials, electrode materials, and heat exchange materials (heat sinks) with "copper/aluminum clad," we respond to the needs for cost reduction and weight reduction. Additionally, our explosive crimping technology is a cold joining method that does not apply heat to the materials, making it difficult for impurities such as alloy layers to form at the bonding interface between copper and aluminum. This results in low electrical resistance and conductivity close to the theoretical values of the materials. ■ETJ(R) Electrical Transition Joint 【Features】 1. Excellent electrical properties. 2. Superior mechanical properties. It has high bonding strength and demonstrates robust characteristics in bending and tensile tests. 3. Excellent heat resistance. The bonding strength does not change even after 5,000 cycles of thermal fatigue testing at 250°C and 25°C. 4. Regarding galvanic corrosion: Our clad is fully bonded, preventing electrolytes from entering the interface, allowing us to prevent galvanic corrosion by simply applying protective paint to the externally exposed surfaces. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Asahi Kasei Corporation has an explosive welding technology that utilizes the instantaneous high energy generated when explosives detonate to metallurgically join dissimilar metals at room temperature. This product significantly contributes to the weight reduction of vehicles, ships, molds, and more. ■ STJ(R) "Structural Transition Joint" STJ(R) is a compact and highly durable structural joint that enables the welded integration of aluminum alloy structures with carbon steel or stainless steel components. ■ Flame-retardant Magnesium Alloy Joint A structural joint made of flame-retardant magnesium alloy and aluminum alloy or stainless steel. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration