1~19 item / All 19 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~19 item / All 19 items

Filter by category

Our electric dust collector adopts constant voltage control to achieve high dust collection efficiency. In conventional power-saving control, sufficient energy-saving effects could not be obtained during operation with low gas load. However, we have successfully developed an improved power-saving control that captures the characteristics of the electric dust collector, significantly enhancing energy-saving effects compared to conventional methods. The improved power-saving control can also be implemented in newly installed or existing electric dust collectors using constant voltage control, so customers considering energy-saving solutions for new or existing electric dust collectors are encouraged to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

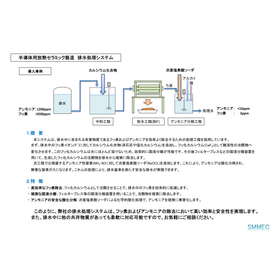

This system is a wastewater treatment solution that combines multiple optimized treatment processes to efficiently remove harmful substances such as fluoride and ammonia contained in wastewater. Our wastewater treatment system reliably removes various harmful substances, ensuring safe and secure wastewater discharge. We also offer customized designs tailored to your needs, as well as on-site surveys and technical support, so please feel free to consult with us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Sumisoba" is a revolutionary and highly efficient gas-liquid contact device that we have uniquely developed based on years of experience and achievements. It demonstrates excellent performance as various types of harmful gas absorption devices, dust collection devices, as well as reaction and cooling devices in processes. We aim for a sustainable society in harmony with the environment by combining this product with unique features and high-performance wet electrostatic precipitators. [Features] ■ Low cost ■ High efficiency ■ Low pressure loss ■ Resistant to clogging *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

IGBT (Insulated Gate Bipolar Transistor) has recently garnered attention as a power semiconductor device for power control, serving as an alternative to traditional thyristors. IGBTs combine high-speed switching performance with excellent power control capabilities, making them widely used in various fields, from household appliances to industrial equipment and renewable energy systems. Our company was the first in Japan to adopt IGBT-based high-voltage power supplies in electric dust collectors. This has achieved significant energy savings compared to conventional methods, reducing power consumption during operation and contributing to lower CO₂ emissions. Our IGBT-based high-voltage power supplies balance energy efficiency and environmental considerations with high-efficiency operation, meeting the diverse needs of our customers. Please feel free to consult us regarding new installations or updates to high-voltage power supplies.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By using it in combination with a closure plate, it completely blocks the outflow of gas in the duct and ensures safety during maintenance.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide a wet electrostatic precipitator that has a high dust and mist removal rate at high voltage, and can easily remove ultrafine particles such as fumes. Due to its cylindrical shape, it is sturdy and maintains its shape over many years of use, allowing it to sustain its initial performance for a long time. Additionally, because of the wide electrode spacing, even when dust adheres and accumulates on the collection electrodes, there is little voltage drop, and performance does not decline. 【Features】 ■ Wide spacing between collection electrodes ■ Constant voltage control method adopted ■ Continuous cleaning method during charging ■ Equipped with a glow discharge extinguishing circuit (fire prevention) ■ Voltage control method that follows the concentration of inlet exhaust gas available as an option (energy-saving) and more *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

High-voltage power supplies for electric dust collectors cannot be installed in areas where flammable gases are present due to the risk of explosion. It is necessary to install the high-voltage power supply far away from the presence of flammable gases and lay a Cottrell cable (paper insulated cable) to supply power to the electric dust collector. However, Cottrell cables have been discontinued for several years, and alternatives are being sought. Our product allows for the high-voltage power supply to be placed in a special pressure-resistant box, enabling installation near electric dust collectors in the presence of flammable gases, thus eliminating the need for laying Cottrell cables.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide a wide range of services related to electric dust collectors. In addition to regular machine inspections and electrical inspections, we offer various repairs, updates to dust collection poles, and upgrades to power supply systems, all aimed at extending the lifespan of equipment and improving performance. We also have solutions for reducing environmental impact, such as reducing CO₂ emissions through energy conservation. - Regular Inspections and Diagnostics We support safe operation of equipment and prevention of troubles through regular inspections of both mechanical and electrical systems. We propose maintenance plans based on inspection results. - Repairs and Parts Replacement In the event of aging or damage, we suggest repair measures or parts replacement to ensure stable operation of the equipment. - Updates to Dust Collection Poles and Power Supply Systems By performing update work due to aging of dust collection poles and power supply systems, we can expect improvements in dust collection efficiency and a reduction in troubles. - Performance Improvement and Longevity We provide various improvement proposals for performance enhancement and longevity based on the operating conditions of the equipment and customer requests. This enables optimization of capital investment and reduction of running costs. - Energy Conservation and CO₂ Reduction By introducing the latest technologies and optimizing operational control, we contribute to reducing power consumption and lowering CO₂ emissions.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts the treatment of heavy metals and other substances based on non-ferrous metal smelting technology. We propose treatment methods tailored to individual wastewater circumstances, such as coexisting substances and required water quality. The target components include heavy metals, light metals, precious metals, metalloids, and semiconductors. 【Target Components (Partial)】 ■ Alkaline earth metals (Ca, Mg, etc.) ■ Rare earth elements ■ Cyanides ■ Organic matter (COD) ■ Oxidizers/reducers (hydrogen peroxide H2O2, residual chlorine, etc.) *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a high-performance wastewater treatment device that adds a nitrate reduction function to the cathode side based on the conventional "N-FreeA system." In this system, nitrate ions (NO₃⁻) in the wastewater are first electrochemically reduced at the cathode and converted into ammonia (NH₃). Next, by reacting with hypochlorous acid (HOCl) generated at the anode, the ammonia is oxidatively decomposed to nitrogen gas (N₂). This process allows for the efficient simultaneous removal of nitrate nitrogen and ammonia nitrogen from the wastewater. Additionally, even if ammonia is already present in the raw water, both nitrate and ammonia can be treated simultaneously, enabling the safe and reliable removal of multiple nitrogen compounds in one go. 【Features】 - Capable of handling wastewater that cannot be treated by biological methods. - No dilution is required, and the high reaction speed allows for space-saving. - No secondary waste (such as sludge) is generated. - Can operate only when treatment is needed (continuous operation is not necessary). - There is no need to treat ammonia and nitrate separately. - Particularly suitable for treating wastewater with high salt concentrations (high electrical conductivity). *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company measures BF4 concentration in real-time and optimizes the amount of BF4 decomposing agent based on the measured values. In the case of batch reactions, the reaction time is approximately within 30 minutes. It can treat BF4- up to 10 mg/L, minimizing the usage of the BF4 decomposing agent. 【Features】 ■ In the case of batch reactions, the reaction time is approximately within 30 minutes ■ Can treat BF4- up to 10 mg/L ■ Minimizes the usage of the BF4 decomposing agent *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts fluoride treatment based on a method that involves adding calcium salts to precipitate and remove fluoride as calcium fluoride. After the removal of calcium fluoride, a defluorinating agent is added to the supernatant to generate calcium precipitation, which adsorbs and removes fluoride. The generated calcium precipitate is reused as a calcium source in the process of precipitating calcium fluoride. Therefore, sludge from additives does not occur. 【Features】 ■ The treated liquid contains almost no calcium. ■ No precipitates other than calcium fluoride are generated. ■ Existing equipment can be repurposed. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company incorporates an ammonia stripping process to reduce the presence ratio of ammonia nitrogen, selectively removing ammonia through anaerobic digestion liquid treatment. To introduce ammonia stripping, we first separate suspended solids (SS) to prevent clogging in the ammonia stripping process and to remove solid COD components, thereby reducing COD load. The COD components remaining after ammonia stripping are treated by combining biological and chemical processes. 【Features】 ■ By incorporating ammonia stripping, the C/N ratio is improved. ■ Since the nitrogen concentration is reduced at the ammonia stripping outlet, the risk of nitrate accumulation in subsequent treatment is low. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts primary treatment through biological treatment methods or coagulation and sedimentation after necessary pretreatment for high concentration and high load COD processing, followed by chemical oxidation treatment on the effluent. We reduce the pollution load within the range that can be treated by biological treatment, which has low running costs, thereby controlling the total running costs. In cases where it is possible to generate poorly soluble organic substances, coagulation and sedimentation may be used instead of biological treatment. 【Features】 ■ Chemical treatment is performed in the later stage to reduce COD concentration to meet discharge standards. ■ Finishing is done with chemical treatment, which is expected to provide stable operation compared to biological treatment. ■ Suitable for wastewater that is difficult to meet discharge standards with biological treatment alone or wastewater that does not operate stably with biological treatment. ■ In the event of temporary trouble with biological treatment, treatment is carried out solely with chemical treatment to cover until the biological treatment is restored. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company treats ammonia nitrogen and COD components using this device (electrolytic device) for harmless processing. For ammonia, it reacts with hypochlorous acid generated at the anode and is oxidized to nitrogen gas. Since hypochlorous acid is generated within this device, there is a cost advantage compared to purchasing it. 【Advantages】 ■ Capable of handling wastewater that cannot be treated by biological methods - No restrictions on raw water nitrogen concentration (can treat high concentrations as they are) - Can accommodate fluctuations in raw water nitrogen concentration ■ No dilution required, and due to high reaction speed, it saves space ■ No secondary waste (such as sludge) is generated ■ Can operate only when treatment is needed (continuous operation is not required) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts nitrate nitrogen treatment that can handle wastewater that cannot be processed by biological methods. Wastewater that cannot be treated by biological methods can also be addressed. No dilution is required, and due to the high reaction speed, it is space-saving, and secondary waste (such as sludge) is not generated. 【Application Cases / Consideration Cases (Excerpt)】 ■ Acid washing wastewater treatment ■ Scrubber wastewater treatment ■ Semiconductor material cleaning wastewater treatment ■ Combined treatment with acid recovery ■ Nuclear-related facility wastewater treatment *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Free Series" is a self-developed chemical treatment process that improves the issues of conventional methods for the treatment of nitrogen, COD, fluoride, etc., aimed at water recovery, recycling, and regulatory compliance. It can be applied to wastewater from various processes such as metal pickling, metal chemical products, semiconductor manufacturing processes, plating processes, catalyst manufacturing processes, and precious metal manufacturing processes. We propose appropriate solutions by combining the distinctive elemental technologies of the "Free Series" with metal separation and purification technology. 【Elemental Technologies】 ■ Nitrate Nitrogen Treatment N-Free N ■ Ammoniacal Nitrogen/COD Treatment N-Free A ■ Fluoride Treatment F-Free ■ Boron Fluoride Treatment B-Free F ■ Nitrate/Ammonia Electrolytic Treatment N-Free AN ■ Heavy Metal Treatment, etc. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide a wet electrostatic precipitator that has a high dust and mist removal rate at high voltage, and can easily remove ultrafine particles such as fumes. Due to its rectangular cylindrical shape, it is sturdy and maintains its initial performance for a long time without significant deformation even after years of use. Additionally, because of the wide electrode gap, there is minimal voltage drop even when dust accumulates on the collection electrodes, ensuring that performance does not decline. [Features] ■ Wide electrode gap ■ Constant voltage control method adopted ■ Continuous cleaning method during charging ■ Equipped with a glow discharge elimination circuit (fire prevention) ■ Voltage control method that follows the concentration of inlet exhaust gas available as an option (energy-saving), etc. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and provides a specialized mercury adsorbent that efficiently adsorbs and removes gaseous mercury contained in exhaust gases. In addition to the conventional lead sulfide (PbS) based adsorbents with proven track records, we have recently developed a new type of adsorbent that uses copper sulfide (CuS) as the adsorbing component, allowing us to offer optimal proposals tailored to various applications and requests. This adsorbent achieves a very high mercury removal rate of 95-98% under operating conditions of an adsorbent layer thickness of 1,500mm and a gas flow rate of approximately 0.2m/s. This high performance is due to the adsorbent's high reactivity and uniform component distribution, making it suitable for a wide range of exhaust gas treatment sites, including various factories and power plants. Moreover, unlike activated carbon-based adsorbents, there is no decrease in removal performance due to moisture in the exhaust gas, allowing for stable high efficiency to be maintained over long periods. Additionally, its performance is less likely to be compromised in environments where sulfur dioxide (SO₂) gas coexists, with expected long operational lifetimes ranging from several years to a maximum of about 10 years. 【Features】 ■ High removal efficiency ■ Low pressure loss ■ Long lifespan ■ Contains almost no Pb (lead) in the adsorbent *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration