- Publication year : 2024

1~2 item / All 2 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~2 item / All 2 items

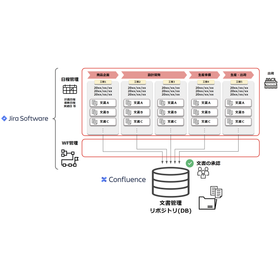

Case studies on the use of Atlassian products for PLM/PDM introduced by INNOOV: manufacturing schedule management, document management, and workflow management. We are implementing manufacturing schedule management, document management, and workflow management in product development using Atlassian products. This will be a talk session with customers.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

INNOOV Inc. has submitted a bid for the announcement of the bid for support in the introduction of optimization development methods using Atlassian products for ITER remote maintenance equipment at the National Institute for Quantum and Radiological Science and Technology (hereinafter referred to as "QST") and has been awarded the contract. At QST, the design and production of the ITER blanket remote maintenance system is underway. There was a need to efficiently manage requirements for the equipment and create documentation in the design, production, and various verification tests of the ITER remote maintenance equipment. By constructing a development workflow using Atlassian software and designing communication within the development team, we aim to support the introduction of optimization development methods for ITER remote maintenance equipment, thereby improving the development speed of the project team and collaboration between teams. By conducting a review on-site once every six months, we extract points for improvement in interactions with related vendors and internal processes. These improvement points will be addressed over the course of six months. Over the past two years of improvement activities, the ITER remote maintenance equipment development team has made progress in modernizing tools and processes.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration