1~18 item / All 18 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~18 item / All 18 items

Filter by category

This is the comprehensive catalog for "Nikkariko," a product that prevents blocking and static electricity. It features a wide range of industrial anti-adhesion agents, including "Nikkariko," which prevents adhesion caused by printing on paper, film, and packs, as well as pressure from vinyl, and also includes the powder spraying device "Electronic Nikkariko K-V Spray." 【Features of Nikkariko】 ■ Manufactured using a unique special method for each variety! It consistently maintains stable quality. ■ A lineup of powders is available to meet various applications and needs. ■ The main raw material is plant-based organic matter! It is a powder with low impact on the human body and high safety. Its safety has been recognized, and it is used as a long-selling brand in countries around the world. Additionally, please refer to the catalog for the powder spraying device K-V Spray. *For more details, please download the PDF or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is the comprehensive catalog for "Nikkariko," which prevents blocking and static electricity. It includes various products such as the industrial anti-adhesion agent "Nikkariko," which prevents adhesion caused by printing on paper, film, and packs, as well as pressure from vinyl, and the powder spraying device "Electronic Nikkariko K-V Spray." 【Features of Nikkariko】 ■ Manufactured using a unique special method for different varieties! Always stable quality. ■ A lineup of powders tailored to various applications and needs is available. ■ The main raw material is plant-based organic matter! It is a powder with low impact on the human body and high safety. Its safety has been recognized, and it is used as a long-selling brand in countries around the world. Additionally, please refer to the catalog for the powder spraying device K-V Spray. *For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

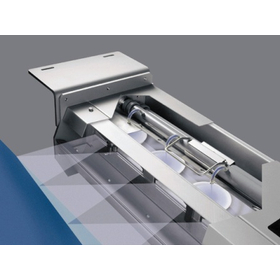

The "WEKO Rotor Dumping" is a device that applies a thin fan-shaped mist of coating liquid onto sheets using a rotor that rotates at high speed driven by a belt. It utilizes centrifugal force to enable uniform, non-contact application at the micron level. 【Features】 ■ Easy control of application amount ■ Very quick changes in application amount ■ Application amount is displayed digitally, allowing for management of the application amount ■ Uniform, non-contact application ■ Application width can be set relative to sheet width Due to its unique features not found in other coating devices, it is adopted in various industries, not only in the plastics industry but also in paper, textiles, non-woven fabrics, and wood. *For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is the comprehensive catalog for "Nikkariko," which prevents blocking and static electricity. It includes a variety of products, such as the industrial anti-adhesion agent "Nikkariko," which prevents adhesion caused by printing on paper, film, and packs, as well as pressure from vinyl, and the powder spraying device "Electronic Nikkariko K-V Spray." 【Features of Nikkariko】 ■ Manufactured using a unique special method for different varieties! It consistently maintains stable quality. ■ A lineup of powders tailored to various applications and needs is available. ■ The main raw material is plant-based organic matter! It is a powder with low impact on the human body and high safety. Its safety has been recognized, and it is used as a long-selling brand in countries around the world. *For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Nikkari Ko Coat Type AS Series Mini Pack Series" is a powder that emphasizes fluidity. It is effective against clumping, caking, and nozzle blockage, and because it is coated, it excels in uniform dispersion and storage stability. Additionally, it has excellent fluidity and slip properties, making it widely used as a slip agent for films, laminates, and more. The Mini Pack Series consists of single-use small bags designed to match the pot capacity of spray devices. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Nikkariko" is a high-performance powder that has received high praise and trust worldwide as a printing back transfer prevention agent, a slip agent for lamination, and various industrial adhesives since its launch in 1961. It is available in various types for different applications, preventing troubles during processes such as blocking and static electricity, thereby contributing to increased productivity. The "Nikkariko Non-Coat Type CD Series" is a powder that emphasizes hydrophilicity. It reduces powder adhesion and dirt on factories, machines, and blankets caused by scattering. It excels in characteristics such as residual blanket, overprinting, and post-processing suitability due to its hydrophilic nature. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Nikkariko" is a high-performance powder that has received high praise and trust worldwide as a printing back transfer prevention agent, a slip agent for laminating, and various industrial adhesives since its launch in 1961. It is available in various types for different applications, preventing issues during processes such as blocking and static electricity, thereby contributing to increased productivity. The "Nikkariko Half Coat Type AS-160" maintains fluidity and dispersibility while suppressing dusting. Additionally, it has excellent post-processing suitability. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Nikkariko" has been a highly regarded and trusted high-performance powder worldwide since its launch in 1961, serving as a printing back transfer prevention agent, a slip agent for lamination, and various industrial adhesives. "Nikkariko Premium Type NP-200M" is made entirely without mineral substances, using plant-based organic materials as its main ingredient, allowing for safe handling as before. The blocking (back transfer) prevention effect has been further enhanced, and due to the reduced residue of powder on the blanket, issues with blanket residue can be resolved. The powder adheres well to the printed areas and efficiently settles on the paper surface, eliminating powder residue that can be problematic during post-processing such as PP lamination. This improves gloss retention and production efficiency in post-processing. By effectively preventing blocking with the minimum necessary application, it is possible to reduce the amount of powder used. As a result, powder scattering around the printing machine is minimized, improving the working environment in the printing area. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Antistatic agent + lubricant "Sirius" for silicon applicators of offset printing machines, "Leo" to enhance the antistatic effect with additional additives, humidifier "Orion" for softening devices, and humidifier "Cassiopeia" for cooling humidifying devices, we offer four types tailored to different machines and applications. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The cleaning agent "Buraclean Series" is a cleaning agent for blankets, ink rollers, guide rolls, etc. We offer a variety of products based on ink solubility, drying speed, and compatibility with cleaning equipment. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Nikka Spray "K-III" is a powder spray device that enables uniform micro-dispersion without using any air. It uses a method of diffusing the powder adhered to the roller surface through high-pressure discharge, allowing for easy adjustment of the spraying amount with the rotation of the roller. The "K-III" is widely used around the world, with approximately 2,000 units shipped primarily in the laminate industry. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Until now, the K-III and K-V sprays were limited in the types of powders that could be sprayed due to the corona discharge method. By adopting a brush roller, it has become possible to spray a variety of fine powders ranging from organic to inorganic materials. Furthermore, based on the anti-drift roller of the K-V spray, a system with even less drift has been implemented, allowing for efficient powder application. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Nikka, which has continued to walk alongside the printing industry, has expanded into other sectors with powder and powder solutions based on the technology cultivated over many years. Currently, we are conveying our unique technology to many companies. We propose optimal solutions with peripheral devices and systems that support the optimization of work environments for improvement. Additionally, we provide a wide variety of supplies (consumables) that are essential for enhancing productivity in various manufacturing sites and improving the quality of final products. In particular, "Nikkariko," which is highly regarded for its safety and used in countries around the world, remains a long-selling brand. Nikka's technology continues to expand its field of activity alongside changes in the times and advancements in technology. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In addition to improving quality, we contribute to stable product creation by achieving reductions in running costs and maintenance. Efficient powder dispersion allows for reduced scattering and decreased usage, and we can solve problems with precise responses based on our expertise in powders and spray equipment. By establishing dust collection methods that consider powder characteristics, we can reduce scattering and improve the factory environment. We will propose and construct optimal equipment from both dispersion and dust collection perspectives. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The productivity of offset printing hinges on how to minimize downtime. The cleaning of blankets by hand takes up the most time, and especially in multi-color machines, the effort and time lost in this task quickly impacts productivity. The "ABS Series," developed from Nikkas' long-standing achievements and experience in "cleaning," is available in various options to meet customer needs. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "WEKO Rotor Dumping" applies the coating liquid as a thin fan-shaped mist picked up by a rotor that rotates at high speed driven by a belt. The overall application width depends on the number of rotors, the basic application amount is determined by the rotor type, and the ON/OFF of the spray application is controlled by the opening and closing of a shutter. Features such as easy control of the application amount, quick responsiveness to changes in application amount, uniform application, and non-contact application have been well received, and it is widely used not only in Japan but also in various countries around the world for applying release silicone, anti-fog agents, and anti-static agents to plastic sheets. Additionally, due to unique features not found in other application devices, it is adopted in various industries beyond just the plastics industry, including paper, textiles, non-woven fabrics, and wood. For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Nikkariko is an industrial anti-adhesive agent that prevents printing and pressure-induced adhesion on paper, film, and packaging. - We offer a lineup tailored to various applications and needs. - It is a powder with stable quality. - It is a powder with high safety and minimal impact on the human body. 【Applications】 From thin paper to thick paper, film, laminate, packaging, etc. *For details, please inquire through a request for materials or download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the conventional Nikka K-3 spray, optional dust collection and static electricity devices were added to address issues such as powder drop and scattering, but a definitive solution had not been reached. Nikka has tackled this problem and, after developing the "Nikka K-4 spray system," has recently introduced the "Nikka K-V spray." This spray device enables a reduction in the occurrence of powder drop and scattering, as well as an improvement in the adhesion efficiency of powder to films. 【Features】 - Significant reduction in powder consumption - Dramatic decrease in powder scattering - Elimination of powder drop - Adoption of an inverter system for drive control of the spray device, allowing for a rotation control range that is twice that of the Nikka K-3 spray - Powder application amount can be set in 1% increments via a touch panel - Monitoring function (high-pressure safety circuit) is standard in the high-pressure circuit of the wiper

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration