1~21 item / All 21 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~21 item / All 21 items

Existing static eliminators are insufficient in removing internal charges from substrates, leading to static electricity issues during the film manufacturing and processing stages. - Printing and painting defects caused by charge patterns and static marks. - Printing defects due to ink splatter and distortion of characters. - Issues caused by insufficient static elimination during roll winding. - Problems arising from increased static electricity during unwinding. - Shifts, repulsion, and peeling of substrates due to static electricity. The nano static elimination device solves such static electricity issues! - If static elimination is performed in the final process, no static electricity will occur on the substrate after roll winding. - Even if static electricity occurs in subsequent transport processes, simply using a conventional static eliminator will maintain the effect. - It resolves static electricity issues that cannot be addressed by existing static eliminators. - Non-contact design ensures no stress is applied to the film. Product Specifications: - Installation is possible if the electrode mounting width is 150mm or more. - Film widths can be accommodated from 0.1m to 10m. - A 50μ PET film can be handled at speeds of 600m/min. - Compatible with clean room environments. - Custom specifications can also be manufactured.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

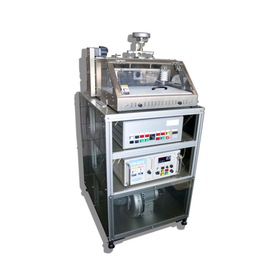

At Wedge, a specialized manufacturer of surface treatment equipment, we offer a wide range of research and development and experimental test devices. We have surface treatment equipment that can accommodate various substrates, including plastic films, sheets, boards, vapor-deposited films, optical films, and high foams. The "Corona Discharge Surface Treatment Device" generates corona discharge in the atmosphere and irradiates the substrate surface to modify it. Even for substrates with low polarity, such as films, non-woven fabrics, and high foams, hydrophilicity is improved, enhancing adhesion, coating properties, wettability, and other functions. Additionally, by using the special high-frequency power supply "CTW Series," surface treatment can be performed with high precision and efficiency through corona discharge. 【Expected Improvements in Substrate Surface Functions】 ◎ Printability ◎ Hydrophilicity ◎ Adhesion ◎ Tackiness ◎ Water Absorption ◎ Adhesion ◎ Wettability ◎ Coating Properties ★ We are currently conducting substrate treatment tests using in-house test equipment. * For more details, please refer to the catalog. Feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The nano static electricity removal device is an electrostatic eliminator (ionizer) that easily removes static electricity from both the interior and exterior of substrates simply by passing through the space between electrodes without contact. It helps suppress coating unevenness and paper misalignment during printing and coating, thereby improving ink adhesion. When used in the final process, it prevents static electricity from occurring on the wound substrate, avoiding stress on the material. It is suitable for environments like the IT industry, where static electricity is highly undesirable. 【Examples of issues caused by static electricity】 - Coating unevenness, ink splatter, and distortion of characters during printing and coating - Paper misalignment due to static electricity - Increased static electricity during unwinding and insufficient static elimination during tall winding - Generation of charged patterns and static marks *If you are experiencing such issues, please contact us for more details or download our catalog for more information.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The nano static electricity removal device is an electrostatic eliminator (ionizer) that can easily remove static electricity from both the interior and exterior of a substrate simply by passing it non-contact between electrodes. It helps suppress coating unevenness, ink splatter, and paper misalignment during printing and coating, and prevents the adhesion of dust and debris caused by static electricity. 【Features】 - When used in the final process, static electricity does not occur on the wound substrate. - Ideal for static electricity countermeasures in places that are very sensitive to static electricity, such as the IT industry. - Does not stress the substrate. *For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Wedge's corona discharge surface treatment device generates corona discharge in the atmosphere to modify the surface of substrates. Even substrates with low polar groups, such as films and non-woven fabrics, can have improved hydrophilicity and enhanced functions such as adhesion, coating properties, and printability by irradiating with corona discharge. Surface treatment can be performed without applying heat to the substrate, unlike flame treatment. 【Enhanced substrate surface functions】 - Printability / Hydrophilicity / Adhesion / Coating properties / Tackiness / Water absorption / Adhesion / Wettability *For more details, please contact us or download and view the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Wedge Plasma Irradiation Surface Modification Device, Plasma Wedge, is a device that enhances hydrophilicity, adhesion, coating properties, and printability on the surfaces of all substrates, including plastics, glass, metals, and their composites, in the atmosphere. - Since it generates plasma discharge in the atmosphere, it does not require a ground electrode. It can modify the surfaces of hollow bottles and molded products with uneven surfaces. - Unlike flame (frame) treatment, it does not apply heat to the substrate. - Thanks to Wedge's unique special power supply, it can process resins, metals, and their composites simultaneously. - It only requires electricity and air, so no complex equipment is necessary. - Additionally, it is equipped with a flexible high-voltage cable, allowing it to operate freely with robots. Its compact design also saves space, making inline integration easy. For more details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi at TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp - Mentioning that you saw this on "Ipros" will facilitate a smooth response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The PHW-1000 atmospheric pressure plasma surface treatment device from Wedge generates a non-electrical atmospheric pressure plasma under atmospheric conditions. By irradiating the substrate surface with non-electrical plasma, it produces hydrophilic polar groups, achieving high wettability. The substrate surface improves foreign substance adhesion functions through enhanced adhesion, printability, paintability, and coating properties. 【Features】 - Generates atmospheric pressure plasma without using special gases. - Being electrically neutral allows for surface modification of conductive substrates such as carbon materials and electronic components. - Capable of treating narrow and recessed areas like aluminum sashes and metal caps. - High-energy plasma discharge demonstrates effectiveness on high-speed moving bodies and various treatment agents. - Adoption of flexible high-voltage cables allows for free movement with robots. - Compact design facilitates easy inline integration. For more details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi at TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp. - Mentioning "I saw it on Ipros" will ensure a smooth response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By irradiating a substrate with a low density of polar groups with corona discharge electrons in the atmosphere, polar groups are generated. As a result, the substrate's hydrophilicity is enhanced, imparting functions such as water absorption, adhesion, and coating properties. 【Evaluation Methods for Wettability】 ● User Standards ● JIS-1907 Bireck Method (Measurement of water absorption by capillary action) ● Measurement of wettability over time using a contact angle meter ● For more details, please contact Wedge Co., Ltd. Electrical Division Sales Representative: Uesugi at TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp. Mentioning "Ipros" will facilitate a smoother response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

High-pressure equipment cannot perform at its best even if the high-pressure power supply has high performance, if there are issues with related products. Wedge can provide comprehensive support from software to hardware, including the design and manufacturing of high-pressure power supplies, load electrodes, special high-pressure power supplies, and high-pressure connectors. We have implemented a design with a strength rating of more than double the nominal value and sufficient insulation measures to reduce issues caused by abnormal discharges due to leakage and insulation degradation, as well as to minimize the energy during electric shock accidents with a safe design. As we manufacture in-house, we have established a system that allows us to respond quickly to customer requests from design and manufacturing to sales and maintenance. 【Applications】 ● Pinning devices (electrostatic adhesion devices) ● Static tension control devices ● Electret processing machine power supplies ● Forced charging high-voltage power supplies for electric fiber opening devices, etc. ● CE mark obtained ● For more details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi at TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp - Mentioning "Ipros" will facilitate a smoother response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

High-pressure equipment cannot perform at its best even if the high-pressure power supply has excellent performance, if there are issues with related products. Wedge can provide comprehensive support from software to hardware, including the design and manufacture of high-pressure power supplies, load electrodes, special high-pressure power supplies, and high-pressure connectors. 【Applications】 ● Power supply for electrostatic painting devices ● Pinhole detectors for resin caps, PET bottles, etc. ● High-voltage power supply for general-purpose electrostatic flocking devices ● High-voltage power supply for general-purpose electrostatic sorting, and others ● For more details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi. TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp ・Mentioning "Ipros" will facilitate a smoother response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

High-pressure equipment cannot perform at its best even if the high-pressure power supply has excellent performance, if there are issues with related products. Wedge can provide comprehensive support from software to hardware, including the design and manufacturing of high-pressure power supplies, load electrodes, special high-pressure power supplies, and high-pressure connectors. 【Applications】 ● Spot peening equipment ● Static tension control equipment ● Power supply for testing electret processing machines, etc. For more details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi. TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp. Mentioning "Ipros" will help facilitate a smooth response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a product made by applying high-voltage power supply technology. ● Product Lineup ○ Dielectric strength testing machine ○ Insulation breakdown testing machine ○ Pinhole detector ○ Electric fiber opening device ○ Pinning device (electrostatic adhesion device) ○ Electret processing machine ○ Electrostatic separator ○ Electrostatic flocking device ○ Forced decharging system, etc. ● For more details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi. TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp ・Mentioning "I saw it on Ipros" will help facilitate a smooth response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

What is an electret? - A substance that permanently retains electric polarization is called an electret. - This device can easily create an electret by passing a highly electrically insulating polymer material through it. Usage examples: - Polymer materials, silicon wafers, new materials for development, special films, non-woven fabrics, etc. Typical products and substrates that have been electretized: - Electret filters, electret condenser microphones, piezoelectric element sensors, masks, electrostatic dust collectors, electret power generation, etc. For more details, please contact Wedge Co., Ltd. Electrical Division Sales Representative: Tanaka. TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp. Mentioning "I saw it on Ipros" will help facilitate a smooth response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Mainly introduced in process lines operating 24 hours a day, this equipment is designed with a strength rating more than double the standard, reducing issues commonly associated with high-pressure equipment, such as leakage and insulation degradation. Additionally, it features a safety design that minimizes discharge energy in the event of sparks or electric shock accidents. 【Components】 ● High Voltage Power Supply (DC High Voltage Stabilized Power Supply) KFVMW Model 300W Type This is a high-performance high voltage power supply that provides stable high voltage to the pinning electrodes. Output Voltage: DC10KV, 15KV, 30KV Output Current: 500mA/max Polarity: Positive or negative output, polarity switchable Ripple Content: 0.01% or less Output Stability: 0.05% or less ● Various Electrodes ● For more details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi at TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp. Mentioning "I saw it on Ipros" will facilitate a smooth response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a device that uniformly implants fine powders of materials (such as pile fibers, plastics, activated carbon, metals, etc.) in a vertical direction onto a substrate that has been pre-coated with adhesive, using the suction effect of static electricity. 【Effects of Use】 - Condensation prevention, aesthetics, light blocking, friction braking 【Examples of Use】 - Air conditioner vents and ducts, automotive interior parts, display stands, cosmetic boxes, inside rubber gloves, inner surfaces of camera hoods, inner surfaces of meter panels, precision equipment transport sections, roller parts, grip sections, medical devices, etc. *There are various types available, including down type, up type, side type, and composite type. *There are also simplified models with built-in high-voltage power supplies and portable types. *We also accept the production of special and custom items. ● For more details, please contact Uesugi from the Electrical Division of Wedge Co., Ltd. at TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp. Mentioning "I saw it on Ipros" will help facilitate a smooth response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Using the repulsive force of static electricity, the filament threads are evenly dispersed from each other. Due to the forced charging method, stable production can be carried out throughout the year without being affected by the surrounding environment, unlike the friction charging method. For more details, please contact Uesugi from the Electrical Division of Wedge Corporation. TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp - Mentioning that you saw this on "Iprosu" will help us respond more smoothly.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A high voltage is applied to the substrate, and a spark is forcibly generated at pinholes or weak points in the insulation to detect defects. 【Features】 - The high-voltage power supply for the wedge is designed to minimize the discharge energy during sparking. - The applied voltage uses a high-voltage stabilization power supply method. - There is almost no discharge marks or carbon adhesion on the workpiece or electrodes due to sparking. - It maintains a very stable output voltage against fluctuations in power supply voltage and load. - There is very little damage to the electrodes, allowing for longer maintenance cycles. For more details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi at TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp - Mentioning "I saw it on Ipros" will facilitate a smoother response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Test Items】 ● Short-term destruction test (automatic mode, manual mode) ● Stepwise destruction test (automatic mode, manual mode) ● Life test 【Types】 ● AC withstand voltage testing machine ● DC withstand voltage testing machine ● DC/AC switchable withstand voltage testing machine ● Constant temperature layer withstand voltage testing machine ● X-Y-Z axis electrode movable testing machine ● For details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi. TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp ・Mentioning "Ipros" will help facilitate a smooth response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Wedge's Static Electricity Removal Devices" 【Product Lineup】 ● Blower-type static electricity removal device ● AC voltage applied static electricity removal device (KACW series) ● DC static electricity eliminator ● Nano static electricity removal device (internal charge removal device) ● DC air-gun type static electricity removal device ● Special type static electricity removal electrodes ・ Flange type electrode ・ Nozzle type electrode ● Spray-type static electricity prevention agent, Eleki Cut ● For more details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi. TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp ・ Mentioning "Ipros" will help facilitate a smooth response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a nano deionization removal device (internal charge removal device) that uses a special electrode developed to solve the problem of internal charges that could not be resolved by existing static electricity countermeasures. 【Examples of Static Electricity Issues】 ● Problems remain unresolved even with the use of high-performance deionizers (ion control method, ion balance method, pulse method, etc.) ● Static electricity reoccurs over time even after removal ● Generation of charging patterns and static marks ● Insufficient deionization during roll winding ● Increased static electricity during unwinding ● Misalignment of paper due to static electricity ● Ink splattering and distortion of characters These phenomena occur because static electricity inside the substrate has not been removed. The "internal charge removal device nano" solves these problems that are difficult to resolve even with high-performance deionizers! 【Features】 ● Static electricity issues can be eliminated simply by passing through the electrode without contact. ● It does not stress the substrate. ● When deionized with the nano deionization device, the effect lasts even if static electricity occurs in subsequent processes, as it can be removed with a general deionizer. ● It can be installed with an electrode mounting width of 150mm. ● A single high-voltage power supply can cover a total effective electrode length of up to 10m.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a device that instantaneously heats the substrate by passing it through the work coil. By combining Wedge's uniquely designed heating power supply with original coils, efficient heating can be achieved. 【Features】 ● It is equipped with an automatic tracking circuit to ensure the best matching against load fluctuations. This is an energy-saving design that can operate at optimal efficiency. ● The work coil adopts a natural air cooling system, so there are no issues related to cooling water like those found in water-cooled systems. ● For large machines, a parallel split type is recommended to consider maintenance in case of trouble. (Example: 100KW equipment → 20KW × 5 units connected in parallel) ● For more details, please contact Wedge Corporation, Electrical Division, Sales Representative: Uesugi. TEL: 06-6885-6273 / FAX: 06-6885-6274 / E-mail: info.wedge-d@webcatch.jp - Mentioning that you saw this on "Ipros" will help ensure a smooth response.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration