1~28 item / All 28 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~28 item / All 28 items

Are you able to prepare the optimal tools immediately when you want to process? The current situation is that many places manage tool information such as inventory status and stock quantities on paper. Our "Tool Management System" significantly reduces the time required for tool preparation, extends the operating time of machine tools, and achieves cost reduction. <What is Industry 4.0?> It is a national project promoted by the German government aimed at advancing the manufacturing industry. The concept is "smart factory." It aims to connect all equipment in the factory to the internet for centralized management, allowing various information such as product quality, operational status, and machine condition to be visualized. 【The following can be achieved】 ◎ It is possible to list the tools required for each workpiece and register them in a database. ◎ Reduction of tool preparation time. ◎ Reduction of tool search time. ◎ Management of various tool information used at the site and factory level. *For more details, please contact us or download the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

ZOLLER is a manufacturer of tool measuring instruments, tool presetters, and tool management systems. The tool measuring instruments have a proven track record of delivery to cutting tool manufacturers worldwide. The tool presetter developed by ZOLLER maintains the potential of the tool measuring instruments. Many customers may have concerns about the setup before processing, such as getting different results when three people measure the same tool, or finding the operation of a simple presetter difficult despite thinking it would be easy to use. ZOLLER can provide proposals to alleviate these various customer concerns. 【Five Points to Alleviate Customer Concerns!】 ■ Repeatability accuracy ■ Verification of the tools used ■ Standardization of tool values ■ One-shot processing ■ Significant reduction in work hours * In addition to the five points, the catalog also introduces case studies. * Demonstration of equipment is also possible in the showroom. * For more details, please download the catalog or contact us using the information below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

ZOLLER's new generation tool measuring device offers a significant advantage with its measurement precision of 1 micron, and this accuracy is guaranteed for 5 years and even 10 years. High-precision measurements enable cost reduction, efficiency improvement, and lower defect rates! For example, in a case where one-shot machining was made possible through boring processing, a cost reduction of 1.2 million yen per year has been achieved. *As it is a precision measuring instrument, annual inspections (calibrations) are necessary, and if you are receiving this paid service, the guarantee extends to 10 years. *We are currently offering a point document explaining the benefits of introducing high-precision tool measuring devices! For more details, please download from the form below. 【Features】 ◆ One-shot machining is possible with boring processing! ◆ Height adjustment of milling cutters is highly precise! ◆ Rapid measurement of multiple locations, such as stepped tools! ◆ Measurement accuracy and repeatability are in the micron range! *Thanks to fully automated measurements, anyone can obtain the same measurement results. For more details, please contact us or download the catalog to view.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

How do you "guarantee" cutting tools? As the demand for precision in cutting processes increases, the requirements for the dimensional accuracy of the tools used have become stricter. Even tools manufactured with high-precision tool grinding machines cannot be used in processing without high-precision measurement (accuracy inspection reports). ZOLLER Japan has clearly summarized the criteria for selecting measuring instruments into five key points. These can be widely utilized in the manufacturing industry, including the automotive sector. *Exclusive for Ipros users! We are currently offering a free "Beginner's Guide to Tool Measuring Instruments" that summarizes the key points!* 【5 Key Points (Excerpt)】 ■ Good repeatability! ■ Easy measurement! ■ Ability to quickly set the measuring tool with high precision! *Demonstration machines are available for demonstration at our showrooms in Yokohama, Nagoya, and Osaka! For more details, please contact us or download our catalog to view it.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

How do you "guarantee" cutting tools? With the increasing demand for precision in machining, the requirements for the dimensional accuracy of the tools used have become stricter. Even tools made with high-end tool grinding machines cannot be used in machining without high-precision measurements (accuracy inspection sheets). ZOLLER Japan has clearly summarized the five key points that serve as criteria for selecting measuring instruments. These can be widely utilized in the manufacturing industry, including the automotive sector. *Exclusive for Ipros users! We are currently offering a free "Beginner's Guide to Selecting Tool Measuring Instruments" that summarizes the key points! 【Five Key Points (Excerpt)】 ■ Good repeatability! ■ Easy to measure! ■ Ability to quickly set the measuring tool with high precision! *Demonstration machines are available for demonstration at our showrooms in Yokohama, Nagoya, and Osaka! For more details, please contact us or download and view the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In cutting processes using machining centers and multi-tasking machines, increasing the machine's operating rate directly reflects productivity improvement. To increase the machine's operating rate and reduce tool costs, the use of tool presetters is common practice. ◎ Right now, we are offering a free "Tool Presetter Beginner's Guide"! 【Seven Key Points of Presetters (Excerpt)】 ■ Does the same value come out regardless of who measures it? ■ Is the measurement accuracy sufficient? ■ Can it accommodate adjustable tools?… *For more details, please request the materials or view the PDF data from the download. ZOLLER Japan will propose the optimal tool presetters according to your needs.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are you able to prepare the optimal tools immediately when you want to process? The reality is that many places manage tool information, such as inventory status and stock numbers, on paper. By combining tool measuring devices with tool management software, we can significantly reduce the time spent preparing tools, extend the operating time of machine tools, and achieve cost reductions! 《Recommended for those who have the following concerns!》 ◎ It takes time to check the combination of cutting tools and holders… ◎ It takes time for confirmation and inspection when loading tools into the machine… ◎ It takes time to check NC programs… *For details, please refer to the PDF data available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

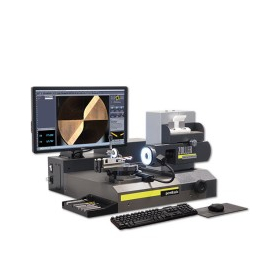

The tool inspection measuring device "pomBasic" enables quick and highly accurate measurements on-site. The operation is simple: set the tool, position it, and measure. Non-contact measurement work avoids damage to the cutting edge and allows for recording the condition of the cutting edge. Additionally, it can generate inspection reports. 【Features】 ■ Achieves high-precision measurement of tools on-site. ■ Non-contact measurement work prevents damage to the cutting edge. ■ Capable of recording the condition of the cutting edge and generating inspection reports. ■ Can be placed right next to the tool grinding machine for fast and accurate measurements. ■ Ideal for tool manufacturers and regrinding businesses. *For more details, please request materials or view the PDF data available for download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introduction of measuring instruments for the measurement and research of cutting tool edge honing, which affects tool life. Is R honing good for the edge honing section? What is the K-factor, which is very important for measuring R honing...? Can we say that edge honing has been measured without measuring the K-factor???

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

*For more details, please contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

How do you "guarantee" cutting tools? With the increasing demand for precision in cutting processes, the requirements for dimensional accuracy of the tools used have become stricter. Even tools manufactured with high-end tool grinding machines cannot be used in processing without high-precision measurements (accuracy inspection reports). Therefore, we have listed the verification items that serve as criteria for selecting tool measurement devices. For more details, please contact us or refer to the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Wouldn't you like to reduce the defect rate in machining? ZOLLER has a proposal to make that happen. For more details, please contact us or take a look at our catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

ZOLLER Japan Co., Ltd.'s bronze, silver, and gold software packages can meet all of your production needs. The software utilizes a modular design, allowing not only for optional increases in functionality but also for enhanced operational convenience. With this software, customers can further improve their profitability. We offer three types: the "Bronze Solution - Tool Management," which enables economical and effective management of all tools, tool parts, and measurement data; the "Silver Solution - Inventory Management," which allows for efficient tool management, effective inventory control, and standardization of production data management through tool management; and the "Gold Solution - Manufacturing Management," which maximizes the efficiency of tool management, enables comprehensive cost control, and realizes the visualization of the process chain. For more details, please contact us or refer to the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the coming years, an increase in demand for large gears is expected. Along with this, the demand for high-level cutting tools will also rise. SANDVIK Coromant is a leading manufacturer that consistently provides solutions in the field of cutting tools for metal processing, while ZOLLER is a leading manufacturer in the development of measurement technology for all cutting tools. This project was initiated under the collaboration of both companies, resulting in improved service for users. For more details, please contact us or refer to the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Have you ever experienced a situation where the tool dimensions used in the program differ from the actual tool dimensions, leading to collisions during processing and incurring huge costs? To prevent such situations, ZOLLER offers »toolrealityCheck«. In recent years, simulation systems have been utilized to avoid such scenarios. However, the basic tool information in simulations often does not match the actual tools, but this issue can be resolved with »toolrealityCheck«. For more details, please contact us or refer to the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

An easy-to-use interface has been developed to facilitate data transfer between the ZOLLER TMS tool management solution database and the ESPRIT CAM system. This option enables easy tool registration and management. Through the joint development of ESPRIT and ZOLLER, programmers can access the ZOLLER TMS tool management solution to search for tools, manage parameters, and handle inventory. Tools can be imported directly into ESPRIT from a database that provides available tools in the familiar ESPRIT tool notation. For more details, please contact us or refer to the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Efficient tool management improves the speed of NC programming, shortens working hours, and is essential for CAM programmers to acquire actual tool data. Therefore, Bombardier will implement a database solution at its Netphen branch (which is engaged in the manufacturing of body shells and train bogies). This solution will include Missler's TopSolid'Cam software and Zoller’s tool management solutions. For more details, please contact us or refer to the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

NOMOS Glashütte is a major player in the watch industry, boasting timeless wristwatch designs. This company is located near Dresden, Germany, and produces high-precision mechanical wristwatches through advanced technology and a wealth of skills, as well as manufacturing tiny components for precision tools. Therefore, when measuring or inspecting these mechanical tools, the most stringent requirements must be met. ZOLLER's tool measuring instruments can fulfill these precision demands. For more details, please contact us or refer to the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Can you prepare the optimal tools immediately? Can each department quickly access information about where they are located, whether they are in stock or not, the quantity in stock, and so on? I believe there are still many places where tool information is managed on paper or manually. This leads to a significant loss of time and can cause human errors. Given the current IT technologies that control production equipment, the aforementioned methods cannot be considered cost-effective for the equipment. While making substantial investments in equipment and tools, please consider implementing a system that focuses on efficiently managing tools, allowing for a more effective recovery of the investment made in the equipment. For more details, please contact us or refer to the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To improve production efficiency and reduce production costs, one key point is to reduce the setup time of equipment. Perfect for those who: ◆ Spend too much time checking and inspecting NC programs and machine-mounted tools ◆ Spend too much time checking NC programs In the downloadable materials: - Why can we reduce production costs by as much as 5 million yen annually? - What are the actual costs that can be reduced? - Actual simulations and other helpful elements are introduced in a total of 28 pages of materials. *You can view the materials via PDF download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"ZOLLER TMS" is a system that accurately measures the shape of tools and selects the appropriate tools for machining tasks. It significantly reduces the preparation time for tools and equipment. Currently, we are offering a collection of case studies filled with tips for increasing production efficiency and reducing production costs! It includes detailed explanations of cases that have successfully achieved cost reductions of over 5 million yen annually, as well as methods for tool management. [Contents] ■ What costs can actually be reduced? ■ Actual simulations, etc. We introduce elements that can serve as hints for efficiency and cost reduction over 28 pages. *For more details, please check the catalog download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The high-performance and versatile tool measuring device "smarTcheck" offers basic functions for manual position adjustment and focus, as well as fully automatic CNC control functions, both of which enable "smarTcheck" to provide measurement results quickly, easily, and with high precision. Additionally, the modular system allows for specifications tailored to individual requirements. For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A proven tool measuring device that has been widely adopted by tool manufacturers and tool regrinding companies around the world. Not only is it highly accurate, but it is also designed to be user-friendly for Japanese users.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The model that has been adopted for many years by American and German automobile manufacturers and related companies can finally be introduced in Japan.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Measuring with an accuracy of 1 micron creates significant advantages. The measurement tool, Venturion, which guarantees that precision even after 5 or 10 years, is not "disposable." I will explain the great meaning behind this term.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will support your purchase with examples and data.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A presetter for quickly and accurately measuring large cutters for crankshaft machining. This presetter can check 120 mounted chips in 80 seconds. Since the cutter itself becomes very heavy, we also provide jigs to facilitate installation and dedicated auxiliary tools to assist with mounting to the presetter.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A high-end dedicated machine that achieves increased work efficiency and nine times the tool life through overwhelmingly fast and consistently controlled presets.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration