1~40 item / All 40 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~40 item / All 40 items

Filter by category

We would like to introduce the "Length Measurement Judgment System Dedicated Tool" that we handle. It determines the quality and variation simultaneously during transport when combined with the length measurement hand. There is no need for complex installation work that requires experts, and it can be used immediately. It can store up to 9999 length measurement data in internal memory, and it is also possible to output measurement history data in CSV format. It can be utilized for dimension management and traceability. 【Features】 ■ Work dimension conversion calculations considering the shape of the hand's jaws ■ Measurement points: 5 positions ■ Measurement results: 5-level judgment output ■ Length measurement data storage and output ■ Easy setup *For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

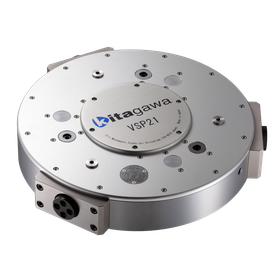

The "VSP21" is a vertical-type dedicated low-grip chuck that can grasp easily deformed workpieces with low gripping force, featuring dustproof and waterproof properties. By adopting a low-friction structure, it maintains stable low gripping force for an extended period, requiring minimal maintenance. Additionally, it gently grips without damaging the workpiece. It is suitable for the polishing and finishing processes of thin disc-shaped workpieces. 【Features】 ■ Ideal for polishing and finishing processes of thin disc-shaped workpieces ■ Static gripping force: 5–18 kN (VSP21) ■ Waterproof and dustproof structure ■ Usable for dry processing ■ Minimal maintenance *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

〇Reduced Maintenance Eliminates the need for maintenance such as backlash adjustment and pitch error correction, reducing machine downtime. 〇Achieves Stable Processing Directly detects the indexing position of the table, ensuring reliable positioning even with uneven load jig work. 〇Excellent Cost Performance More affordable compared to conventional encoder specifications. 〇Diverse Specifications Compatible with rotary joint installation. *Inquiries required.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- Special seals and air purge shut out the intrusion of particles such as chips and grinding dust into the main body. - Purge structure with low air consumption (0.3L/min). - Low heat generation seal structure. - Long-lasting seals. - Structure that allows for easy cleaning and replacement of the seal area. - Compact body thickness. - Patent pending.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

● Lightweight and compact design ● High precision position reproducibility ● Long lifespan and high rigidity

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

● You can use the existing BR/BRT chuck and soft jaws as they are for the quick jaw change chuck. ● There is no mistake in the installation of the serration position, and the serration position will be the same regardless of who installs it. ● Even after removing and attaching the jaws, the gripping accuracy is 0.01mm T.I.R. There is no need for re-shaping when changing jaws.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Built-in cylinder driven by a rotary joint on the machine side Wide processing area secured due to the slim body High-speed rotation of 3000 min-1 High gripping accuracy of 0.01 mm T.I.R. Gripping force maintained even during hydraulic down due to built-in lock valve Equipped with one port at the chuck center, usable for seating confirmation, etc. Tnut-Plus available (optional) Slide seal can be installed (optional)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The slim 2-finger parallel shield gripper 'NPL216S' is a robot hand that allows for the measurement of the gripping part's dimensions while transporting the workpiece, thanks to its built-in scale. With its unique sealed structure, it achieves dust and water resistance without the need for air purging. It can be used in harsh environments, reducing the risk of failure, which contributes to minimizing equipment downtime, maintenance labor, labor savings, and increased productivity. 【Features】 ■ Usable in harsh environments where chips, dust, and cleaning occur ■ Supports IP67 dust and water resistance by connecting an additional hose for ventilation ■ Capable of transporting heavy workpieces due to high internal gripping force ■ Contributes to energy savings and cost reduction by reducing piping and air consumption ★ We will be exhibiting at "JIMTOF2024" held at Tokyo Big Sight from November 5 to 10! In addition to this product, we plan to showcase a demo of automatic jaw exchange, new chucking proposals, and the announcement of other new NC rotary table products. We sincerely look forward to your visit. (Booth number: W2011) *For product details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Joe can confirm seating without floating after horizontal movement and retraction. High gripping accuracy with 0.01mm T.I.R. Lightweight and low inertia body. Slim design ensures a wide processing area. Ideal for thin workpieces that are prone to distortion with low gripping force and high-speed rotation. Retraction adjustment is possible on the lathe. Tnut-PLUS is available (optional). Dedicated for external diameter gripping.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

○ Usable in harsh environments such as cutting powder, dust, and cleaning (IP67) ○ Capable of transporting heavy workpieces due to high inner diameter gripping force ○ Achieves dustproof and waterproof without air purging ○ Option available with measurement function

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It can be mounted on a 30-number MC with a compact and lightweight design. Ideal for processing aluminum workpieces! The roller gear cam mechanism maintains stable precision over a long period and achieves non-backlash indexing. The rotary joint supports a total of 7 ports, including 6 hydraulic and pneumatic ports plus 1 multi-purpose hole. Maximum work size: Φ500xH270.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- Ideal for environments such as cutting powder, dust, and cleaning (IP67) - High inner diameter gripping force - Unique sealing structure for reduced piping

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Features】 - Maximum clamping force of 20kN (Note 1) - Grips the bottom of the material with a minimum gripping length of 3.5mm for five-sided machining - Low-profile body provides a wide machining range and good tool accessibility - Hardened body ensures high durability - Capable of rough and finish machining with a single unit (Note 2) - Repeatability accuracy of ±0.01mm (Note 3) (Note 1) Torque wrenches and sockets for wrenches must be purchased separately. (Note 2) When using optional combination jaws (Note 3) When tightening without using parallel plates on the finishing surface of the optional combination jaws

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This catalog introduces the robot hands handled by Kitagawa Iron Works. It features high-quality, durable standard model parallel grippers "NTS Series," parallel hollow grippers "NTB Series," and slim two-finger parallel grippers "NPGT Series," among others. Please use this for selecting products. [Contents (excerpt)] ■ Parallel Gripper "NTS Series" ■ Parallel Hollow Gripper "NTB Series" ■ Slim Two-Finger Parallel Gripper "NPGT Series" ■ Slim Two-Finger Parallel Gripper Scale Specification "NPGT_S Series" ■ Quick-Jaw Change Gripper for Reduced Setup ■ Quick-Plate Change Gripper (for panel replacement) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Cutting processing with ultra-high pressure water. Capable of high-speed processing, reducing work hours. 【Features】 ○ Can be introduced at a low cost ○ Reduces processing time to less than 1/4 compared to cutting plotters (according to our research) ○ Can be installed in a compact space ○ Specialized for processing rubber, resin, and gaskets ○ Easy operation (equipped with dedicated CAD/CAM)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Kitagawa Iron Works has launched a web showroom called "Kitagawa WEB SHOWROOM," which consolidates technical information about machine tools. Here, we provide technical information about our products, accept inquiries from customers, and showcase new and featured products to enhance customer convenience. Currently, we have published technical information on chucks. We will continue to add content regarding technical information in the future, so please stay tuned. We sincerely look forward to your visit. ★Visit the web showroom here★ https://prod.kiw.co.jp/exhibition/mtools/ 【Contents Included】 ■ Soft Jaw Search ■ Hard Jaw Search and Gripping Range ■ Scroll Chuck Jaw Search ■ Parts List Search ■ Main Unit Addition - Working Range Diagram ■ Power Chuck Composition ■ Power Chuck Operation Mechanism and Classification ■ Gripping Examples ■ Usage Precautions ■ Information on Grease ■ How to Set Gripping Force ■ How to Attach to the Machine ■ How to Remove from the Machine ■ Disassembly and Assembly Methods ■ Failures and Countermeasures *For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The robot hand is equipped with a built-in scale, enabling the measurement of the workpiece gripping area. In addition to the conventional functions of "grasping" and "transporting," it now includes the function of "dimension measurement." With the ability to measure dimensions during the transport process, it is now possible to sort items based on their dimensions and conduct inspections between processes, replacing human involvement. This contributes to labor reduction and space-saving by eliminating the need for personnel involved in inspections, as well as inspection equipment, devices, and locations. *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A standard chuck that achieves a high gripping accuracy of 0.01mm T.I.R. or less. The lift of the jaws is minimal, allowing for secure workpiece fixation, contributing to improved machining accuracy. It is also compatible with finishing processes. By using the optional special T-nut, T-nut-Plus, a repeatability accuracy of 0.01mm T.I.R. or less is achieved even after jaw replacement! Due to the high repeatability of the jaws, an integrated claw that can handle high-speed rotation can be used, significantly improving setup changes and machining efficiency. Note: In the case of BR12, it will be 0.015mm T.I.R.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The best specs in its class are condensed into a small body. It achieves effortless processing with powerful clamp torque. The compact effective thickness, which excels in mounting, also improves chip evacuation. The compact built-in rotary joint is available in 4-port, 5-port, and 6+1 port options, and it supports multi-purpose ports and high-pressure types.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The sophisticated high-performance design achieves a thickness reduction of up to approximately 40% and a weight reduction of up to 50% compared to conventional models. This gripper, made by a chuck manufacturer, realizes high restoration accuracy. The "NPGT_S series," equipped with an optional length measurement scale, enables dimension measurement of the workpiece gripping section! We propose new applications for the gripper, such as "transport + measurement inspection." Additionally, it comes with various options, including magnetic sensors, proximity sensors, and models with through holes (NPGT10). [For more information about the NPGT_S series, visit this URL] https://www.ipros.jp/product/detail/2000546664

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Processing by cutting with ultra-high-pressure water. The cutting efficiency increases by mixing in abrasives. 【Features】 〇 Water supply is pressurized to ultra-high pressure using a high-pressure pump, allowing processing to be carried out with water only. 〇 Minimal thermal impact during processing. 〇 No dust dispersion, achieving a clean working environment. 〇 Capable of handling a variety of workpieces. 〇 Mixing abrasives with water for processing makes it optimal for hard materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A gripper with a large through hole, ideal for jig attachment. It features a high-rigidity body treated with hard anodizing, ensuring long life and sustained high precision over extended periods. It can securely grasp heavy workpieces with high gripping force. The compact body achieves a thinner and lighter design, allowing for disassembly and cleaning without removing it from the robot. Maintenance has also been improved.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By simply replacing the master jaw of our general-purpose gripper "NTS Series," it quickly transforms into a quick jaw change gripper! Tool-less jaw replacement is possible, significantly reducing setup time during jaw changes. One set of jaws can accommodate multiple gripping diameters ranging from φ23 to φ79. *For more details, please check the video.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Quick Plate Change Gripper "QGB Series" allows for easy plate replacement with just a simple operation of loosening the lock nut! The lightweight and compact design of the plates can be selected according to various conditions such as the shape and size of the workpiece. Since it is manually replaceable, it minimizes the number of teaching points, reducing the setup time for new workpieces! It is equipped with six grooves for mounting reed switches, allowing for the use of different sensors in the program, eliminating the need for troublesome sensor replacements.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A high-precision, high-gripping force gripper packed with the know-how of chuck makers. Its structure excels in chip prevention and maintainability, reducing the burden of maintenance on customers. It achieves a compact design that does not limit the robot's payload, enabling high-precision assembly tasks with smaller robots.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The workpiece can be closely attached to the reference surface, allowing for stable heavy cutting without any lifting. Due to the structure that backs up the sliding surface of the master jaw, it maintains high precision stably even with repeated use. It is also compatible with automation, and seat confirmation can be implemented. *For more details, please refer to the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a two-stage gripping type where the jaw moves in parallel to grasp the workpiece and then sits in a retracted position. It features a dust-proof and grease-sealed structure, making it ideal for mass production processing and automation line implementation with high durability and low maintenance specifications. It adopts serrated jaws, allowing customers to easily shape the jaws themselves. *For more details, please refer to the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is compatible with the B-200 series. By adopting a side wedge mechanism, we have achieved a 30% reduction in claw lift compared to conventional standard chucks. The reduction in lift makes it easier to manage dimensions in the Z-axis direction from the locator, similar to a retractable chuck. *For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "TT150" is a 5-axis compatible inclined NC rotary table. It can be mounted on a #30 small machining center. It features a compact design that minimizes overall height, reducing the high column amount on the machine side. By fully integrating a rotary joint as an option, it achieves simple and reliable fixture piping. ● For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "CKR160" is an NC round table with a body thickness (table height) of 99 mm, making it one of the thinnest in its class. It features a blockless structure rotary joint and can support 7 ports (pneumatic/hydraulic). It is an ideal product for space-saving machines. For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The piston has been maximized in size and a new clamping method has been introduced, achieving the strongest clamping torque! This reduces machining distortion. The high-rigidity body, optimized design, and structural features improve rigidity retention. The high clamping torque leads to increased cutting speed and reduced cutting cycles. It also contributes to shortening clamping operation time and tact time.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It can be mounted on the 30-type small machining center (100mm high column). It is compatible with a fully integrated rotary joint (5 hydraulic ports, 1 pneumatic port). Since the supply piping is centralized and there are no protrusions on the side, interference checks can be easily conducted when mounted on the machining center. It adopts a roller gear cam reduction mechanism, which eliminates the need for backlash adjustment due to aging, making it excellent for low maintenance. *For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It fits perfectly on the compact M/C of class 30. The high-rigidity steel body is a low-profile type that allows for a large machining area. The aluminum jaws come standard, and the opening is the largest in its class. In addition to stable clamping force provided by the mechanical boost mechanism, it minimizes lifting, enabling machining with stable precision. It comes in a standard parallel configuration. *For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

For over half a century, KITAGAWA chucks have earned high trust from customers around the world. This is due to our strict quality control of high-precision and high-quality products, ensuring a manufacturing system that can be used with confidence. Our chuck series, equipped with cutting-edge catching technology that continues to evolve, flexibly responds to various processing conditions. We take pride in our wide range of variations, meticulous support, and technology backed by unique know-how, challenging the unknown in work holding. 【Product Lineup】 ○ Chuck Series ○ Cylinder Series ○ Work Gripper Series For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

High clamp torque, high precision, and high rigidity. By adopting a special alloy containing hard metallic intermetallic compounds in the material base, wear resistance has been significantly improved compared to conventional methods. 【Features】 ○ Excellent wear-resistant worm wheel material ○ High clamp brake system ○ High tooth worm with a large diameter design that emphasizes strength and rigidity For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Vice Clamping Series" incorporates a maintenance-free power amplification mechanism called the "toggle joint mechanism," achieving stability with a significant clamping force that is not found in hydraulic vices. Since the clamping force is preset, adjusting the force is easy. Additionally, manual clamping without amplification is also possible, providing excellent usability. It allows for accurate and reliable positioning with stable clamping force. 【Features】 ○ Compact design ○ Reliable, stable, and easy clamping ○ Achieves workpiece lift of 0.015mm or less ○ Easy jig attachment For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Since its establishment in 1941, Kitagawa Iron Works Co., Ltd. has engraved the mission of being a manufacturing company in our hearts and has been challenging itself in manufacturing and development. The environment surrounding businesses changes rapidly in every era, but the spirit of "monozukuri" (manufacturing) that we at Kitagawa have cherished from our founding to the present has been passed down unwaveringly across generations. Through our manufacturing, we aim to gain even greater trust from our customers and take on the responsibility of supporting the rich lives of people around the world by continuing to pursue new products, new technologies, high-quality services, and new challenges in development. For more details, please contact us or download our catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our customized chucks are compatible with all types of workpieces. From mass production machining machines to special dedicated machines, we select the perfect gripping method, such as retractable grips and face lamps, to provide technology that demonstrates stability. ◎ You can check work examples for each series from the "Download" section.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Eternal Year, based on the processing achievements cultivated through lathes and CNC know-how, combines high speed, high precision, and high rigidity, creating a Neo Machine that meets the highest industry standards by quickly incorporating market needs. 【Features】 ○ Light cutting processing of non-ferrous materials: Ideal for resin, lightweight metals, and wood processing. From materials like plastic, FRP, and CFRP to models of automotive parts and inspection jigs. ○ 3D processing through 5-axis simultaneous control. Achieves high-speed, high-precision, and high-value-added processing.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Friction welding of dissimilar materials with high precision, high strength, and in a short time. We propose an environmentally friendly joining method that utilizes heat generated by friction. 【Features】 ○ High dimensional accuracy and reproducibility ○ Strong joint strength ○ Joining of components that are difficult to weld ○ Capability to join dissimilar materials ○ Energy-saving and environmentally friendly ○ Cost reduction For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration