A new material for high-slip bearings with added strength to bronze: Copper Stainless [MTA-HLS20] has been born.

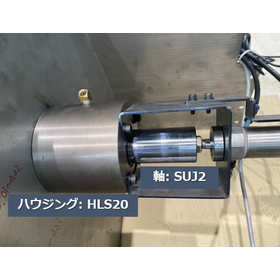

The copper stainless steel bearing material HLS20 is a stainless steel bearing material characterized by its copper content. During axial motion, trace amounts of copper precipitate on the surface, serving as oil, making it a groundbreaking oil-free bearing material that reduces friction heat. Moreover, it is much more affordable than phosphor bronze while improving performance, making it a very user-friendly material. With the cooperation of a bearing manufacturer, a test was conducted using SUJ2 for the shaft and HLS20 for the bearing over 17 days with 5 million reciprocal wear cycles, resulting in a maximum temperature difference of +3°C.

Features of MTA-HLS20:

1. A copper stainless steel alloy containing 20% copper, with excellent castability and machinability.

2. It has a high melting point, high corrosion resistance, and dirt resistance, making it ideal for high temperatures, corrosive, and marine environments.

3. It possesses high strength characteristics, excellent wear resistance, and precision maintenance in high-load usage environments.

4. It can be used without solid lubricants like carbon, significantly reducing processing costs associated with carbon insertion.

5. It is in the same price range as bronze alloy materials while offering superior wear and corrosion resistance compared to copper alloys.

6. It solves friction/wear issues in mechanical components, reducing production costs and improving mechanical performance.

Inquiry about this news

Contact Us Online