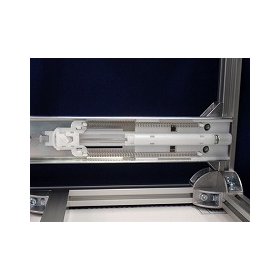

We are developing the model 3401EC, which features an easy close mechanism (EC) for the heavy-duty model 3401.

The evaluation tests for the basic functions of this new model, the 3401EC, are nearly complete, and we are currently finalizing preparations for mass production. We plan to finalize the specifications and start mold production by the end of this year. Samples produced with the molds are expected to be shipped after March next year. This model is expected to offer various advantages for storing relatively heavy units (around 80 kg) in financial terminals and other applications. Specifically, when a unit is stored with strong force, a strong impact can occur on the unit and the main body before it is completely closed, typically due to stoppers on the slide rails. This can negatively affect other devices and components on the main body. The 3401EC mitigates this impact with a shock absorber just before fully closing, allowing the unit to be drawn in gently from that position. Additionally, when closed quietly, a light push is all that is needed for the spring to pull it in and close softly. As a result, the frequency of replacing parts affected by impact is reduced, leading to overall cost savings. This product is planned to be offered as standard items, with even-numbered model numbers ranging from 20 (slide length 508 mm) to 30 (slide length 762 mm).

Inquiry about this news

Contact Us Online