Achieving improved productivity in extrusion molding.

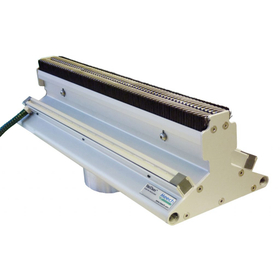

The continuous screen changer is designed to minimize resin leakage that occurs during screen switching (when the bolts slide). In extrusion molding, contamination of the molded products can lead to a decline in quality. However, stopping the production line for screen replacement to prevent this issue reduces production efficiency, making it a constant topic of improvement in manufacturing environments. This screen changer operates with the upper and lower bolts working in tandem, allowing for the switch to a new screen (breaker plate) without reducing the filtration area efficiency, thus achieving increased productivity without halting the entire production line.

Inquire About This Product

basic information

【Features】 - Continuous molding is possible even during screen replacement. - Simple structure requiring minimal maintenance. - Maximum pressure 70MPa, maximum differential pressure 10MPa, maximum temperature 350℃.

Price information

-

Delivery Time

Applications/Examples of results

For more details, please contact us.

Company information

The world standard for resin pressure sensors! We are the world's first manufacturer of resin pressure sensors, boasting a global market share of approximately 70%. Leave the measurement of pressure and temperature of high-viscosity and high-temperature (up to 600℃) fluids to us! Additionally, we offer online viscometers and tabletop MI meters (melt indexers), among others.

![[Data] HITECH Screen Changer](https://image.mono.ipros.com/public/product/image/bdf/2000550075/IPROS87199580206947297432.png?w=280&h=280)