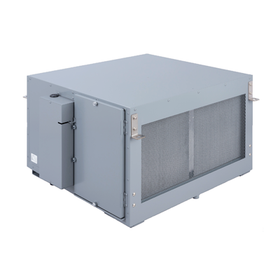

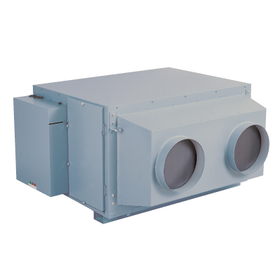

Water flow-type environmental improvement devices "Kesumakku" and "Mist Grip"

KS-6 type, KS-7 type

A water flow-type environmental improvement device that does not require a blower. It is effective in a wide variety of industries. It addresses issues such as oil smoke, odors, and dust.

Kesmac Mist Grip is optimal for environmental measures both inside and outside factories. Are those in the manufacturing industry struggling with complaints related to environmental issues, heatstroke prevention, and odor control due to the revised Air Pollution Control Act and specific offensive odor substances, as well as concerns from neighbors, local authorities, and labor environment improvement? Kesmac Mist Grip is already used in a wide range of industries, including many in the food sector, chemical manufacturers, construction materials, and metal-related fields. Our company itself became a model factory (textile-related) at our Hanwa factory in 2002, incorporating various know-how and successfully implementing odor control measures.

Inquire About This Product

basic information

While processing with electric dust collectors and filter-type odor control devices is mainstream, the dust adhering to the electrodes significantly reduces the dust collection function and requires frequent maintenance. Moreover, there is also a risk of fire. Additionally, filter-type systems incur high running costs for filter replacements. In contrast, Kesmac and Mist Grip can treat exhaust with just a small amount of neutralizing agent using water, electricity, and materials, allowing running costs to be reduced to less than one-fifth of those of combustion-type systems. Furthermore, the collected substances are decomposed and recovered in a separation tank, making the equipment virtually maintenance-free. This versatility allows them to handle not only the oil mist generated from tenter processing in dyeing factories but also the oil mist and odors from quenching and tempering in metal processing plants, as well as odors from food factories, phenolic odors, ammonia odors, mercaptans, hydrogen sulfide, amine odors from plastic factories, and solvents such as formaldehyde, DOP plasticizer mist, and alcohols from formaldehyde-intensive factories. For factories adjacent to urban areas, it is crucial to avoid issues with neighboring residents regarding exhaust and problems related to the working environment both inside and outside the factory.

Price information

Due to the customized nature of the product, the price varies depending on the materials used.

Price range

P5

Delivery Time

Applications/Examples of results

The smoke and odors from quenching and tempering in metal processing plants, as well as the phenolic, ammonia, mercaptan, hydrogen sulfide, and amine odors from plastic factories, and the formaldehyde, DOP plasticizer mist, and solvents such as alcohols emitted from formaldehyde-intensive factories.

catalog(1)

Download All CatalogsCompany information

Asahi Kako Co., Ltd. manufactures and sells various types of fibers, as well as odor control and dust, vapor, and oil smoke management devices such as the water flow-type environmental improvement devices "Kesumakku" and "Mist Grip," which address formaldehyde, various amines, methyl mercaptan, ammonia odors, chlorinated odors, IPA alcohols, hydrogen sulfide, DOP plasticizers, and oil smoke, along with the S-shaped heat recovery device "Ecomerit" for recovering waste heat from contaminated warm wastewater.

![[Field Report] Measures Against Exhaust Odors in Tire Manufacturing Plants (Demonstration Available)](https://image.mono.ipros.com/public/product/image/075/2000639337/IPROS13116499983758750705.png?w=280&h=280)