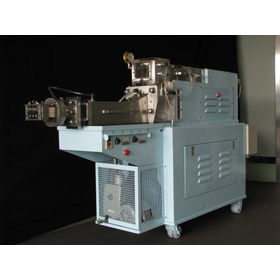

Please make use of our vacuum mixing extrusion molding machine for your prototypes and mass production equipment. It continuously molds shapes up to approximately φ150.

Our company's vacuum mixing and extrusion molding machine achieves integration by combining the mixer and extruder into one unit, allowing for precise mixing with a single molding machine. It is ideal for the extrusion molding of products made from materials such as ceramics, activated carbon, metals, and food. We offer custom design and manufacturing based on the properties of the materials and production volumes. Continuous molding is performed for various shapes of nozzles ranging from φ15 to φ150. By equipping our unique mixing function with a color mixing screw developed from our original ideas, the mixing capability is enhanced. The internal temperature of the device during molding is generally maintained between cold water at -3°C and hot water at 80°C. For the production of molded products such as resins, we can manufacture molding machines with heater heating (up to 180°C). Note that our extrusion molding tests are limited to hot water (up to 80°C). The disassembly and cleaning of small molding machines (approximately V-25) can be completed by two people in about 20 minutes.

Inquire About This Product

basic information

Our company proposes, designs, develops, manufactures, and sells vacuum kneading extrusion molding machines tailored to each customer's raw materials, shapes, and molding characteristics. In particular, we can achieve highly precise molded products for customers who require precision kneading. Conventional horizontal vacuum kneading extrusion molding machines are optimal for molded products ranging from φ15 to φ150. On the other hand, for molded products ranging from φ180 to φ300, we recommend vertical extrusion machines. These vertical machines can maintain the molded shape by extruding large molded products in the vertical direction under the influence of gravity. In addition to molding machines, we also manufacture mixers, conveyors, dryers, and other related equipment. For customers considering the introduction of molding machines and other equipment, or those wishing for product development or prototype molding, we invite you to utilize our extrusion molding tests. During the initial assessment test, we will take your raw materials and conduct extrusion molding free of charge. Afterward, once you have conducted your analysis, please consider our paid molding tests. For more details, please visit our website and contact us. https://www.universe-kk.co.jp/

Price information

Please contact our Kyushu factory directly. TEL: 0954-66-2872 Email: kyushu@universe-kk.co.jp

Delivery Time

Applications/Examples of results

Molding materials: ceramic, activated carbon, metal, food, etc. Molding shapes: honeycomb, sheet, round rod, pipe, filter, etc. Applications of molded products: electronic devices, VOC countermeasures, deodorization, air purification, etc.

Detailed information

-

V-30

-

V-70

-

V-90

Line up(5)

| Model number | overview |

|---|---|

| V-15 Tabletop Model | ▼Processing Capacity: 0.3–1kg/H ▼Device Power: 0.1kw ▼Material Screw Diameter: φ15mm ▼Machine Dimensions: L750xW180xH320mm ▼Machine Weight: 45kg ※The numbers listed are for reference only |

| V-25 | ▼Processing Capacity: 4–6kg/H ▼Device Power: 0.75–1.5kw ▼Material Screw Diameter: φ25mm ▼Machine Dimensions: L1,600xW500xH1,300mm ▼Machine Weight: 500kg ※The numbers listed are for reference only |

| V-55 | ▼Processing Capacity: 25–45kg/H ▼Device Power: 3.7–5.5kw ▼Material Screw Diameter: φ55mm ▼Machine Dimensions: L3,000xW650xH1,600mm ▼Machine Weight: 2,000kg ※The numbers listed are for reference only |

| V-90 | ▼Processing Capacity: 100–180kg/H ▼Device Power: 5.5–7.5kw ▼Material Screw Diameter: φ90mm ▼Machine Dimensions: L5,000xW1,000xH2,000mm ▼Machine Weight: 6,000kg ※The numbers listed are for reference only |

| V-150 | ▼Processing Capacity: 300–450kg/H ▼Device Power: 18.5–30kw ▼Material Screw Diameter: φ150mm ▼Machine Dimensions: L8,500xW1,100xH2,800mm ▼Machine Weight: 20,000kg ※The numbers listed are for reference only |

catalog(1)

Download All CatalogsCompany information

Our company specializes in extrusion molding. For over 50 years since our founding, we have continued to pursue advanced technology in vacuum kneading extrusion molding. We ask both customers introducing equipment and those developing extrusion molded products to start with extrusion molding tests. In the initial extrusion molding test for evaluation, we will hold your materials and use our vacuum kneading extrusion molding machine to check if molding is possible. After that, we ask you to evaluate the molded product and consider whether to continue using our services. We primarily focus on the design, development, manufacturing, and sales of custom-made vacuum kneading extrusion molding machines tailored to each customer's materials. Additionally, customers developing extrusion molded products can utilize our paid extrusion molding tests as many times as needed. While our expertise lies in ceramic-based materials, we also have a track record with carbon, metals, and food products. In extrusion molding, we will leverage our years of experience to provide satisfactory services and products that can fully reflect our customers' needs.

![[Delivery Example] Dehydrated Cake Slurrification](https://image.mono.ipros.com/public/product/image/930/2000521133/IPROS57935937473516739738.jpeg?w=280&h=280)