We offer a selection of trays that are anti-static, oil-resistant, and conductive, suitable for robot assembly.

A Robo Tray is a parts supply tray that can be used for picking and inserting by automated assembly robots active in automated factories. Based on 20 years of experience since its initial sale, we have made improvements and can propose shapes and materials (such as anti-static, oil-resistant, heat-resistant, and conductive) tailored to our customers' applications. Additionally, Kanayama Kasei has achieved low prices, high quality, and short delivery times through a consistent system that includes design, mold production, tray molding, and recycling. Since everything is done in-house, there is no concern about confidential information leaking to the outside. Being a foam product, it also helps protect parts during logistics. If the size is within 800×600×240H (maximum external dimensions), we can manufacture it to specified sizes. For more details, please contact us or refer to our catalog.

Inquire About This Product

basic information

【Product Lineup】 ○General Purpose Type → By standardizing the external dimensions, it is possible to reduce mold costs. ○Thin Type → Designed for lightweight and small component storage, allowing for an increase in quantity within the tray feeder (changer). → Excellent in terms of economic efficiency, including logistics. ○Box Type → Capable of deep boxes up to 240H, which was not achievable with conventional molding methods. ○Oil and Chemical Resistant Type → Combines oil resistance and chemical resistance, preventing tray deterioration due to grease and cleaning agents, thus prolonging the cycle. ○Kit Type → Allows for the storage of 10 to 20 parts in one tray, enabling the assembly of finished products with just one type of tray. ● For more details, please contact us or refer to the catalog.

Price information

Please contact us.

Delivery Time

※Please contact us.

Applications/Examples of results

【Delivery Achievements】 ○ Home Appliances → Televisions, digital video cameras, video decks, refrigerators, air conditioners, washing machines, microwaves, mini discs, vacuum cleaners, etc. ○ Office Automation, Information, and Communication → Computers, word processors, FAX machines, copiers, printers, ink ribbons, displays, mobile phones, electronic devices, etc. ○ Automotive → Engines, bodies, shafts, electrical components (gauges, car navigation systems, audio systems), etc. ○ Housing Equipment → Water heaters, sanitary equipment, lighting equipment, etc. ○ Health Equipment → Medical devices, etc. (magnetic material components, circuit boards) ● For more details, please contact us or refer to the catalog.

catalog(2)

Download All CatalogsCompany information

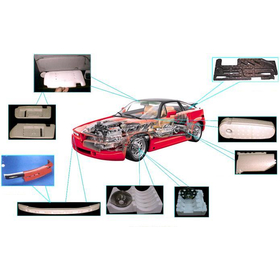

Currently, various foam resin products are being utilized in many settings around us. They are extensively used as packaging and cushioning materials, including various electrical appliances and office equipment, as well as in fish boxes and floats for aquaculture, to the extent that it is impossible to count each individual application. Kanayama Kasei has been advancing the development of applications for this highly versatile foam resin. As a result, its areas of application have further expanded, and now include insulation structural components for air conditioners and refrigerators, various structural insulation materials for buildings, decorative formwork materials for construction and civil engineering, lost foam casting models for the casting industry, robotic trays for parts supply to automated assembly robots in factories, and automotive interior materials, covering all fields from manufacturing to logistics and sales. This can be said to be the result of our outstanding utilization technology breathing new life into foam resin, and Kanayama Kasei products, which respond swiftly to societal needs, significantly contribute to cost reduction for users, fostering a trusted partnership between users and Kanayama Kasei.

![Embossed tape component supply tray "Koujiro Flex" [Component transport fixture]](https://image.mono.ipros.com/public/product/image/4c7/2000401444/IPROS67857123939404863717.jpeg?w=280&h=280)

![Rose part supply tray "Koujiro Trim" [Part transport jig]](https://image.mono.ipros.com/public/product/image/890/2000401167/IPROS23972051774008487322.jpeg?w=280&h=280)

![[Column] Management Strategies for Starting Materials in Active Pharmaceutical Ingredients](https://image.mono.ipros.com/public/product/image/3e5/2000710289/IPROS06292587954207697823.png?w=280&h=280)