The 700t forging equipment has a dedicated line for iron sleepers.

The 700t forged product "iron sleeper" from Tanaka Nobutetsu Co., Ltd. undergoes incoming inspection after the material is received, followed by hole drilling and heating forging at four locations. One out of every 40 pieces is inspected, and then the iron sleeper undergoes bending with a hydraulic press at both ends, cold bending work, final inspection, and packaging, before being shipped nationwide in dedicated JR freight containers. For more details, please contact us or refer to the catalog.

Inquire About This Product

basic information

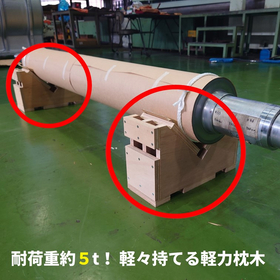

【Features】 ○ Jointly developed patented products ○ Material inspection upon arrival ○ Hole processing on materials ○ Heating forging at four locations only ○ Inspection of one out of every forty pieces ○ Hydraulic press for bending both ends of iron sleepers ○ Cold bending work → Final inspection → Packaging ○ Shipped nationwide in dedicated JR freight containers 【Business Introduction】 ○ Conducting rough processing through free forging with hammers and hydraulic presses, specializing in die forging ○ Using friction presses (screw presses) for competitive press machines ○ Capable of mass production as well as small lot production of various types ○ Challenging product manufacturing for various industries ● For more details, please contact us or refer to the catalog.

Price information

Please contact us.

Delivery Time

※Please contact us.

Applications/Examples of results

For more details, please contact us or refer to the catalog.

catalog(1)

Download All CatalogsCompany information

Tanaka Nobu Iron Works Co., Ltd. is engaged in the manufacturing of products as a die forging company located in Nogata City, Fukuoka Prefecture (Nogata Industrial Park). Since its establishment by my grandfather, Nobu Tanaka, we have upheld the principles of trust, responsibility, and sincerity as our corporate motto, and our employees work together as one. The economic situation in the industrial sector is extremely challenging, and we feel a strong sense of crisis and responsibility. Although we are a small company, we leverage our extensive experience to enhance our technical capabilities, with veteran craftsmen and mid-level and young employees working together to take on daily challenges in forging and processing. We specialize in die forging using screw presses, which is rare nationwide, and we uniquely combine it with free forging. Even with the limited number of die-forged products, we strive to meet our customers' needs and make proposals accordingly. Furthermore, moving forward, we aim to increase the added value of technologies and manufacturing methods that only Tanaka Nobu Iron Works can provide, with a focus on distinctive production methods and forged products.

![Reliable, safe, and stable quality sleepers [preservative-treated and painted].](https://image.mono.ipros.com/public/product/image/05e/2000557973/IPROS69382555548068980835.jpeg?w=280&h=280)

![[Esco Special Selection] Resin Sleepers (Liprag) ★Custom Order Available★](https://image.mono.ipros.com/public/product/image/9bf/2000558317/IPROS96215032317655202839.jpeg?w=280&h=280)