World's first! Shear heating type grain alpha-amylase pulverizer

HSM-250/HSM-090 (with) waist

Grains that are primarily composed of starch can be instantly gelatinized (converted into a paste) into powder through heating and grinding!

In the conventional method of producing alpha-starch rice flour, multiple processes such as cooking (gelatinization), drying, and grinding were necessary. However, with this device, by heating the raw rice between the grinding stones (heaters), moisture, heat, and shear force from the stones act on the raw rice, resulting in gelatinization and simultaneous grinding, allowing for the production of alpha-starch rice flour in a single step. Compared to alpha-starch rice flour produced by conventional methods that include cooking and drying processes, this method suppresses issues such as discoloration, degradation of aroma, and aging. It is also applicable to other grains besides rice, such as alpha-starch adzuki bean flour (instant strained bean paste) and buckwheat flour (buckwheat mousse).

Inquire About This Product

basic information

**Features** - By simplifying the manufacturing process, it is possible to efficiently produce alpha rice flour. → No need for large drainage treatment facilities due to the absence of a cooking process. - The stone milling method allows for grinding and alphaization while retaining umami. **Expected Uses of Alpha Rice** - Food additives such as adhesives - Porridge for nursing care (improving absorption) - Raw material for gluten-free rice flour bread - Emergency food supplies for disaster situations *For more details, please feel free to contact us.*

Price range

Delivery Time

Applications/Examples of results

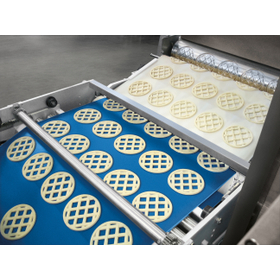

Rice noodles

catalog(1)

Download All CatalogsCompany information

To create high-quality products, powder technology is an essential foundational technology. Since our establishment in 1968, we have consistently strived to acquire high-level powder technology. In particular, our contract processing division has become our mainstay, having cultivated extensive experience and achievements. We have responded to a wide range of customer requests, handling the processing of many materials and refining various processing techniques such as crushing, classification, mixing, drying, coating, and compounding. The fine powder products developed using the processing technologies gained from our extensive contract processing experience are our original offerings. These products utilize our unique chemical grinding technology, enabling us to achieve a level of grinding that cannot be obtained through other grinding methods, as well as allowing for special processing such as compounding with inorganic materials, compounding between resins, and surface coating.