Reduce high-temperature corrosion and effectively extend the tool's lifespan.

Generally, the surface of the RGD series is coated with Ni (30wt% or 55wt%) and copper (50wt%). The coating layer reduces high-temperature corrosion through the retention of diamond abrasives, effectively extending the tool's lifespan. Mesh: 50/60-500/600

Inquire About This Product

basic information

Our company is a craftsman diamond manufacturer. We have obtained ISO 9001:2008 certification, which guarantees the quality and stability of our supply. Additionally, we have a strict quality control system that rigorously monitors quality from raw materials to shipment. For every shipment (including sample shipments), we retain samples from the same lot. If there is ever a quality issue, we can surely trace it back to the original cause. Thanks to this management system, our products have been exported to over 40 countries, earning the absolute trust of our customers.

Price information

0.01 - 0.1 USD/CT The price varies depending on the quantity, so please feel free to contact us.

Delivery Time

P2

※We will definitely ship within three days.

Applications/Examples of results

Generally, the surface of the RGD series is coated with Ni (30wt% or 55wt%) and copper (50wt%). The coating layer reduces high-temperature corrosion through the retention of diamond abrasives, effectively extending the tool's lifespan. Mesh: 50/60-500/600

Detailed information

-

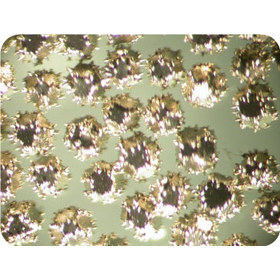

RGD10 (Resin Bond Mesh) Features: It is an economical resin bond diamond abrasive with a polycrystalline structure, light green color, and irregular shape, providing both high grinding efficiency and long service life due to its high-strength brittle crystals. Applications: Suitable for processing hard alloys, ceramics, glass, and non-metallic materials such as PCD.

-

RGD20 (Resin Bond Mesh) Features: This is a standard resin bond diamond abrasive. It has a polycrystalline structure, a green blocky shape, intermediate brittleness, and good self-sharpening properties. Applications: Suitable for wet or dry grinding of ceramics, glass, and hard alloys such as tungsten.

-

RGD30 (Resin Bond Mesh) Features: It is a premium resin bond diamond abrasive. With a polycrystalline structure, gray color, and semi-blocky shape, it possesses high brittleness and excellent self-sharpening properties. Its good micro-fracture characteristics ensure excellent grinding efficiency and remarkable effects for polishing high-demand surfaces. Applications: Suitable for lapping hard alloys such as tungsten and ceramics. Mesh: 50/60-400/500

-

RGD Coating Typically, the RGD series is coated with Ni (30wt% or 55wt%) and copper (50wt%). The coating layer reduces high-temperature corrosion through the retention of diamond abrasives, effectively extending the tool's lifespan. Mesh: 50/60-500/600

Line up(4)

| Model number | overview |

|---|---|

| RGD10 (Resin Bond Diamond) | Features: This is an economical resin bond diamond abrasive. It has a polycrystalline structure, a light green color, and an irregular shape, consisting of high-strength brittle crystals, providing both grinding efficiency and service life. Applications: Suitable for processing non-metallic materials such as hard alloys, ceramics, glass, and PCD. Mesh: 50/60-400/500 |

| RGD20 (Diamond for Resin Bond) | Features: This is a standard resin bond diamond abrasive. It has a polycrystalline structure, a green blocky shape, moderate brittleness, and good self-sharpening properties. Applications: Suitable for wet or dry grinding of ceramics, glass, and hard alloys such as tungsten. Mesh: 50/60-400/500 |

| RGD30 (Diamond for Resin Bond) | Features: This is a premium resin bond diamond abrasive. It has a polycrystalline structure, a gray color, and a semi-blocky shape, featuring high brittleness and excellent self-sharpening properties. With good micro-fracture characteristics, it excels in grinding efficiency and has a remarkable effect on polishing high-demand surfaces. Applications: Suitable for lapping hard alloys such as tungsten and ceramics. Mesh: 50/60-400/500 |

| RGD Coating | Generally, the surface of the RGD series is coated with Ni (30wt% or 55wt%) and copper (50wt%). The coating layer helps retain the diamond abrasive, reduces high-temperature corrosion, and effectively extends the tool's service life. Mesh: 50/60-500/600 |

catalog(6)

Download All CatalogsNews about this product(5)

Company information

ZZDM SUPERABRASIVES CO., LTD. is located in the Zhengzhou High-tech Industrial Development Zone and is a comprehensive company engaged in research and development, production, and sales. Our company is situated in a beautiful environment with convenient transportation. We can provide various types of diamond and CBN superhard materials. These products are widely applied in fields such as cutting, vanishing, and boring. We are a leading manufacturer of industrial diamonds in China. Relying on skilled craftsmanship, advanced production capabilities, and a strict quality management system, we offer competitive products to overseas customers. Additionally, we have obtained ISO9001:2008 certification, ensuring the stability of quality and supply. To date, our products have been exported to over 40 countries in Europe, America, and Asia, earning a good reputation. With the corporate philosophy of "craftsmanship, integrity, and win-win," we look forward to cooperating with your company.