Cooling filter vaporization heat conduction cooling device [Significant effect on cost reduction]

Cooling filter evaporative heat conduction cooling system that demonstrates significant effects in energy saving and cost reduction for commercial air conditioning and refrigeration/freezer rooms.

Effects of Cooling Devices Environmental measures such as energy conservation, cost reduction, CO2 reduction, and addressing the heat island phenomenon. It can prevent high-pressure cut-off, increase cooling capacity in summer, and reduce power consumption through peak cutting. In extreme heat conditions where the outdoor temperature exceeds 30°C, the temperature around the air conditioning unit can sometimes reach nearly 40°C, making heat exchange impossible. By installing a cooling filter on the outdoor unit, heat exchange efficiency can be improved by about 20%, and power consumption can be reduced by 25% to 35%. ● Characteristics of Cooling Devices ○ Prevention of corrosion and scale buildup on the outdoor unit heat exchanger fins. ○ Prevention of high-pressure cut-off in air conditioning units. ○ Easy installation and maintenance of parts. ○ No unnecessary consumption of cooling water. ○ Improvement of air cooling capacity and extension of equipment lifespan. ○ Prevention of debris accumulation and clogging on the condenser. ○ Energy savings (reduction of power consumption and CO2 emissions). ○ Measures against heat islands and shading effects. ○ Inexpensive and cost-effective power reduction devices. ○ Hybrid method using thermal conduction cooling and evaporative cooling. *For more details, please request materials or view the PDF data from the download section.

Inquire About This Product

basic information

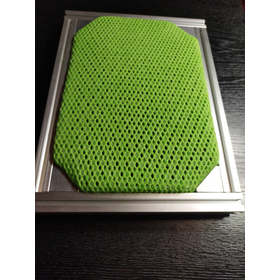

The cooling filter does not directly spray water onto the heat exchanger; instead, it is designed to come into contact with a special cooling filter that has water absorption and retention properties, making it easy to create a uniform wet surface. This allows for cooling of the heat exchanger through the latent heat of vaporization generated on the back side of the filter and the thermal conduction of the filter body, enhancing the heat dissipation effect of the outdoor unit. ● Evaporative Cooling This is a cooling system that utilizes the latent heat of evaporation of water to improve the energy efficiency of the outdoor unit. The cooling filter reduces the cooling load of the equipment by cooling the air drawn in from the intake with the latent heat of water evaporation, promoting energy savings in power consumption. It is evident that the evaporative cooling effect increases with higher outdoor temperatures and lower humidity, and that faster airflow and larger evaporation surface areas further enhance the cooling effect. ● Conductive Cooling Thermal conduction is the phenomenon where heat moves from a high-temperature area to a low-temperature area when a temperature difference exists within an object. When a cooling filter (a porous material containing water) is closely attached to the heat exchanger of the outdoor unit, heat transfer occurs between the two objects with different temperatures. Ultimately, the temperature of the heat exchanger becomes uniform with the water temperature.

Price information

We will provide a quote based on the horsepower. (We accommodate outdoor units from various manufacturers.) For inquiries, please contact 090-8704-7730 ✉ maruko-eng@blue.ocn.ne.jp

Price range

P2

Delivery Time

P4

Applications/Examples of results

This is a cooling device that cools the condenser by directly installing a cooling filter containing water in close contact with the surface of the heat dissipation fins of the outdoor unit equipped with a heat exchanger for heat exchange, allowing for heat transfer between them. By directly contacting and transferring heat within the object, a larger surface area results in a greater amount of heat transfer. The cooling filter maximizes the surface area exposed to air, increasing the amount of heat exchanged at the surface and efficiently enhancing the heat exchange rate. Manufacturing industries such as factories and plants consume large amounts of energy, which is accompanied by a significantly high volume of CO2 emissions. Efforts to promote energy conservation in energy-intensive factories also address various environmental issues surrounding the Earth and are considered an important challenge in tackling global warming. Medical facilities that operate air conditioning equipment 24 hours a day, businesses primarily engaged in food management that have large-scale refrigeration and freezing facilities, and manufacturing plants require systems that achieve energy savings while prioritizing comfort and quality maintenance. Our company contributes to energy conservation through power reduction technology for hybrid cooling filter outdoor units that utilize heat conduction cooling and evaporative cooling.

Detailed information

-

●Cooling Filter Material The filter material is flexible and can hold about three times its own weight in water, allowing for excellent water movement, diffusion, and absorption, which facilitates labor-saving measures such as the automation of water supply. Instead of directly spraying or dispersing large amounts of water onto the heat exchange and radiation area, it utilizes minimal water through capillary action due to surface tension, thus avoiding unnecessary water consumption. Additionally, it requires no power or other energy sources. For this reason, it is easy to manage and incurs no costs, allowing the cooling filter to demonstrate its wettability instantly.

-

●Intermittent Automatic Water Supply Adjustment of water supply through intermittent operation Spraying and stopping based on temperature sensor and timer settings Control to minimize water usage without wasting cooling water. Water supply control settings ○ Reservations for operation/rest on holidays are possible ○ Pre-scheduled start and end times for water supply ○ Efficient watering and stopping according to outside temperature.

catalog(1)

Download All CatalogsCompany information

A hybrid cooling system using heat conduction cooling and vaporization cooling for outdoor units of cooling devices supports energy conservation for various facilities, factories, and supermarkets. We are comprehensively working on energy-saving measures and CO2 reduction tailored to customer needs. Effects of the cooling device include cost reduction through energy savings, CO2 reduction, and environmental measures against issues like the heat island effect. It can prevent high-pressure cut-off, enhance cooling capacity in summer, and reduce power consumption through peak cutting. In extreme heat conditions where the outdoor temperature exceeds 30°C, the temperature around the air conditioning unit can sometimes reach nearly 40°C, which may hinder heat exchange. By installing a cooling filter on the outdoor unit, heat exchange efficiency can be improved by about 20%, allowing for a reduction in power consumption by 25% to 35%.

![[Case Study] Construction Example of High-Temperature Facilities in Factories Using High-Performance Heat Insulation Sheets](https://image.mono.ipros.com/public/product/image/962/2000579577/IPROS04218491152233419232.jpeg?w=280&h=280)