Automation equipment for implementation boards contributing to labor saving and cost reduction.

It will automatically disconnect according to the specified program.

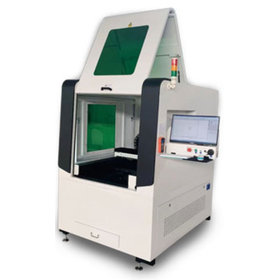

The implementation board "Auto Cutting Machine" is a device that automatically removes and divides assembled circuit boards from a cassette without relying on human hands. Unlike conventional machines, it does not use a shearing method, so there is no stress applied to the mounted components. It uses reference holes to hold the boards vertically, and according to the specified program, it automatically and accurately cuts and divides them in both vertical and horizontal directions using a diamond cutter, even without perforations or V-cut grooves. 【Features】 ○ Automatically and accurately cuts circuit boards according to the division pattern. ○ Simply set the board, allowing for multiple machines and a 40% increase in productivity. ○ Eliminates the need for V-cut groove processing, significantly reducing labor and costs. ○ Easy to integrate into an inline system. ○ Improved cutting accuracy and increased yield. For more details, please contact us or download the catalog.

Inquire About This Product

basic information

【Specifications】 ○ ACM-OG Series ○ Target substrate: Resin substrates (glass epoxy, composite, paper, phenolic) (Ceramic substrates are also possible with different specifications) ○ Substrate size → Height MAX 320mm Width 100mm to 300mm (*Restrictions on vertical cutting position) ○ Component height: Top MAX 30mm Bottom MAX 8mm ○ Component mounting range: Cutting interval of 0.5mm or more ○ Cutting position alignment: Substrate reference holes (at least 2 required) ○ Capability → 20–30mm/sec (depending on the material) with diamond cutter φ60mm×0.5mm ○ External dimensions: Width 900mm × Depth 810mm × Height 1850mm ○ Air source: 0.5MPa (5Kga/cm²) or more ○ Power supply: Single-phase AC100V±10% 50/60Hz (10A or less) ● For more details, please contact us or download the catalog.

Price information

Please contact us.

Delivery Time

※Please contact us.

Applications/Examples of results

For more details, please contact us or download the catalog.

catalog(1)

Download All CatalogsCompany information

EM Tech Co., Ltd. was founded in 1985 in Toyama City as "Fukusho." In 1990, we established E&M Trading Co., Ltd., and in 1991, we increased our capital and changed our company name to EM Tech Co., Ltd. EM Tech specializes in the manufacturing of industrial robots that are optimal for streamlining and automating production processes. We take pride in our commitment to quality control and safety in the manufacturing process. EM Tech Co., Ltd. brings the visions of various industries to life through our unique technology.

![Star Techno | [Labor-saving] Assembly Automation Reduces 7 Workers [Case Study]](https://image.mono.ipros.com/public/product/image/b50/2001532109/IPROS15194842560675155540.png?w=280&h=280)