Equipped with high-speed cutting, high-precision ram, and grip feed!

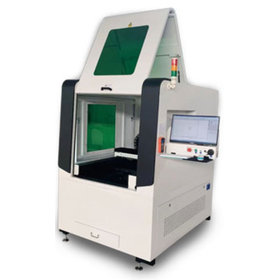

At Asahi Sanak Co., Ltd., machines with five or more forging processes are referred to as "Parts Formers." Based on the "SF Series Parts Former," which is equipped with high-speed cutting, high-precision rams, and grip feeds that enable the molding of high-precision products, Asahi Sanak is developing a series (SRF Series and SGF Series) with the concepts of reducing setup time and compacting the machines. 【Features】 [SRF Series Parts Former 6 die 7 die] ○ Reduction of setup time ○ Compact machine design (simple and slim structure) ○ Reduction of adjustment work inside the machine [SGF Series Parts Former 6 die] ○ A compact former that enables size 1/N For more details, please contact us or download the catalog.

Inquire About This Product

basic information

**Features** [SRF Series] ○ Equipped with a horizon installer → Adopts a method that allows operators to easily perform die and punch block exchanges manually. ○ Reduces core deflection of products due to thermal effects → The die block employs a structure of individual blocks divided by process. ○ Compact design of the machine. [SGF Series] ○ Miniaturization of equipment through phase difference ram configuration → Achieves half the frame weight and miniaturization of other drive systems. ○ A crankshaft with defined forming timing for each process and independently structured rams allow for load distribution. ○ Changes in forming timing for each process help distribute the load and achieve equipment miniaturization. ○ Compared to conventional models, the equipment size has a footprint reduced to 1/6 and height reduced to 1/3. ● For more details, please contact us or download the catalog.

Price information

Please contact us.

Delivery Time

※Please contact us.

Applications/Examples of results

For more details, please contact us or download the catalog.

catalog(1)

Download All CatalogsCompany information

At Asahi Sanak Co., Ltd., we provide a comprehensive service from mold development to the development of new functions for forging machines under the concept of "NetShaper" to realize the forged products our customers seek. Additionally, starting from the Forging Technology Center (FTC), we disseminate the latest information that leads to improvements in mold lifespan and retrofitting of forging machines, building a continuous relationship with our customers based on trust. We pursue the creation of forging machines that achieve "difficult processing quickly" and "with higher precision" through a consistent development process that includes not only functional and mechanical development but also prototyping and product evaluation in our research laboratory. Furthermore, the development of molds optimal for our customers' high-precision products is handled individually by our Mold Division. Since our founding, we have inherited the spirit of "heart and skill," valuing our unique technology, and have established a consistent production system from processing frames and cams to assembly and finishing, achieving high precision and quality that meets our customers' trust. To ensure that you can use our machines in the best condition at all times, we support our customers with a robust engineering service system. The latest technologies of cutting-edge machines and specialized service techniques are consistently maintained to follow production sites for a long time.