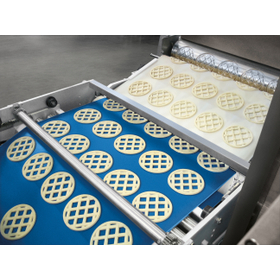

Various shapes can be freely created! Enjoy "fresh pasta" at the store with ease.

The "Compact Pasta Machine II MPC-2500" from Fuji Seiki Co., Ltd. is a noodle-making machine that produces authentic fresh pasta from flour in just a few minutes. By simply changing the shape of the nozzle, you can create various types of pasta. Performing mixing in a vacuum state (optional) removes air bubbles from the flour, allowing moisture to penetrate thoroughly, resulting in a uniform dough that can be made in a short time. 【Features】 ■ Space-saving design ■ Achieves a unique chewiness ■ Easy operation ■ A wide variety of shapes *For more details, please contact us or download the catalog.

Inquire About This Product

basic information

【Specifications】 ■Production capacity: 75 meals/hour Note 1 ■Power supply: AC100V single phase (50/60Hz) ■Power consumption: 0.8KW ■Weight: Approximately 100Kg ■Installation dimensions (mm): 420 (width) × 650 (depth) × 525 (height) Note 1: Varies depending on the customer's dough conditions and weight. *For more details, please contact us or download the catalog.

Price range

Delivery Time

Applications/Examples of results

For more details, please contact us or download the catalog.

catalog(1)

Download All CatalogsCompany information

Our company was established in 1962 as a manufacturer of automatic molding machines for "manju" and "ohagi" (sweet rice cakes). Subsequently, leveraging the technology of the "molding machine," we conceived the idea of creating a machine to make rice balls, leading to the birth of Japan's first automatic rice ball molding machine in 1970. Since then, we have developed various machines tailored to the scale and needs of our users, including "molding machines," "rice ball robots," "bento robots," "IH rice cooking robots," "sushi rolling machines," "inari sushi machines," and "sushi robots." We have also developed and sold noodle machines, pasta machines, and onboard cameras, currently offering about 70 models. We continue to propose and provide systems that create added value through labor-saving and automation in industries such as convenience stores, sushi, dining out, station bento, school lunches, bread making, Japanese sweets, and noodles.