Products that were previously impossible are now achievable with electron beam irradiation! Features of 10MeV electron beams are also introduced!

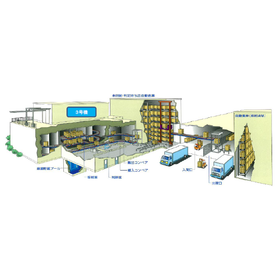

At the electron beam irradiation facility owned by Kansai Electron Beam Co., Ltd., processing of products that were previously impossible to sterilize using conventional methods is now possible with 10 MeV electron beams. This technology is utilized for sterilization and disinfection of everyday products, as well as for enhancing the performance of semiconductors, plastics, textiles, and more. Additionally, research and development of new products and technologies (utilization in university and corporate research) can also be conducted. 【Features of 10 MeV Electron Beams】 ■ High permeability - Equivalent penetration performance to gamma rays due to irradiation from both sides ■ High dose rate - Electron beams have a high dose rate, allowing irradiation to be completed in a short time ■ High reliability - Technical support from Atomic Fuel Factory Co., Ltd. *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Equipment Overview】 ■ Electron Accelerator - Acceleration Pressure: 10MeV (one of the largest in Japan for commercial use) ■ Facility Specifications - Production Facility: Two-story steel structure (partly reinforced concrete) Approximately 60m long × 40m wide - Warehouse: Single-story steel structure Approximately 45m long × 25m wide ■ Certifications Obtained - ISO9001, ISO13485 (Medical Devices) - ISO11137-1 (Medical Device Validation) ■ Registered Manufacturing Facility for Medical Devices *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Kansai Electron Beam Co., Ltd. conducts sterilization and disinfection through electron beam irradiation, as well as material modification. In the sterilization process, medical devices, pharmaceutical containers, food containers, and sanitary products are irradiated. Additionally, for material modification, a variety of products are irradiated with the aim of improving functionality through cross-linking, decomposition, polymerization, and other processes of polymer materials.

![Radiation (Gamma rays, Electron beams) irradiation service [An eco-friendly sterilization method!]](https://image.mono.ipros.com/public/product/image/2f6/2000247577/IPROS7251653149095077698.jpg?w=280&h=280)

![[Consultation for Irradiation Test Available] Electron Beam (EB) Irradiation Service](https://image.mono.ipros.com/public/product/image/111/2000604268/IPROS96737597922580112461.jpeg?w=280&h=280)