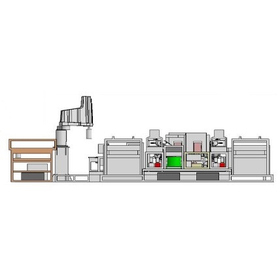

Robot Automation Solution "Electrical Component Assembly Inspection Robot Device"

A robotic solution to automate the assembly of electrical components and inspection after assembly!

The "Electric Component Assembly Inspection Robot Device" is a machine that performs the assembly and inspection of electrical components. It retrieves components from a tray using a horizontal scara robot and utilizes four vertical multi-joint robots to assemble parts, including riveting and screw tightening tasks. By correcting position variations and acquisition errors during assembly with a vision camera, stable assembly is achieved. Additionally, an automatic inspection is conducted after assembly using a vision camera. 【Features】 ■ Custom hands are manufactured to match the customer's products. ■ Proposals for the optimal configuration and layout for the customer's factory. ■ Compatible with robots from any manufacturer. *For more details, please refer to the catalog or feel free to contact us.

Inquire About This Product

basic information

For more details, please refer to the catalog or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the catalog or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Mitsuiwa understands and utilizes the strength of human and on-site capabilities (analog) to support the transition to digitalization with a long-term perspective from the customer's viewpoint. Since the establishment of Mitsuiwa Corporation (formerly Mitsuiwa Shoji Co., Ltd.) in 1964, we have been responding to the increasingly sophisticated and diverse ICT needs of our customers for over 50 years. By providing ICT services and electronic device products, we solve customer problems and challenge ourselves with new businesses that anticipate next-generation needs, continuing to grow and contribute to society. Since entering the industrial robot business in 2012, we have emphasized the necessity of integrating FA (Factory Automation) and IT by accumulating experience in the FA industry. Currently, we are actively supporting our customers in their transition to "smart factories."