Mass-produced items and long rolls suitable for thin materials [Rotary processing machine, high-speed press processing]

High-speed, large-volume, continuous half-cut and full-cut processing that is impossible with conventional press processing is possible! By using a pinnacle die, it also reduces mold costs!

We have a rotary processing machine that wraps a Pinnacle die (trademark of Tsukaya Knife Manufacturing Co., Ltd.) around a magnet cylinder, allowing for rotary processing with roll-shaped molds. Since it punches and presses materials in a rotary manner, it enables high-speed, large-volume, continuous half-cut and full-cut processing that is impossible with conventional press processing, all in a roll-to-roll format. Lamination, cutting, and waste removal can be performed in a single process, and within a single die-cutting roll, combinations of different shapes and complex shapes can be freely created. ● Suitable for high-volume production products ● Thin materials with long roll lengths This processing is ideal for mass production products. Instead of machining cylindrical molds, we use Pinnacle dies, which also allows for cost reduction of the molds.

Inquire About This Product

basic information

Rotary Processing Machine (HK200S) Die Cutting (Die Cutting Section) - Roll circumference: 6 to 12 inches - Effective width of magnet: 150 mm - Rotary speed: 0 to 80 m/min (variable speed by inverter) Maximum material width: 200 mm, effective width: 140 mm Equipped with tension control and skew correction functions, it is possible to vary the die cutting speed in relation to the outfeed speed, allowing for fine adjustments even with materials that may slip.

Price range

Delivery Time

Applications/Examples of results

- Weak adhesive and low adhesive sheets with perforations These are weak adhesive and low adhesive sheets with perforations that can be easily cut by hand, used for transporting and protecting the surfaces of glass and acrylic sheets. Processing without a separator and partial adhesive layer blocking (adhesive killing) can also be performed.

Detailed information

-

5-ton press machine A 5-ton press machine developed in-house. The in-house developed product is painted in blue, which is the image color of Otis.

-

Perforation processing of protective film Perforation processing is performed on protective film used for transporting acrylic and glass sheets, allowing for easy manual cutting.

-

HK200S Rotary Processing Machine

catalog(2)

Download All CatalogsCompany information

Our company is an electronics parts manufacturer that specializes in die-cutting functional materials such as films, double-sided tapes, and cushioning materials. Among these, smartphone components have been adopted by all domestic manufacturers and some overseas, currently accounting for 70% of our total sales and becoming our flagship product. There are many die-cutting manufacturers around the world, but our significant strength lies in the fact that we design and develop most of our processing machines and molds in-house. This allows us to quickly introduce new products as needed, enabling us to respond swiftly to rapidly changing demands and smoothly accommodate specification changes for remodeling.

![[Technical Introduction] Vibration Welding](https://image.mono.ipros.com/public/product/image/823/2000491116/IPROS30362599939175189628.png?w=280&h=280)

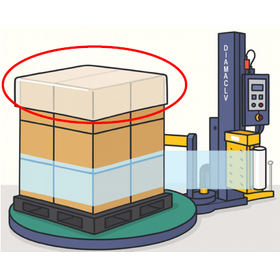

![Stretch Film "Komaki" [Industry First! Optimal for ECO and Work Efficiency!]](https://image.mono.ipros.com/public/product/image/474/2000317425/IPROS17167699807860247107.jpeg?w=280&h=280)