Are you having trouble sourcing brass, copper alloys, or phosphor bronze coil materials?

Mitsui Sumitomo Metal Mining, Mitsubishi Shindou, PMC materials, and other companies have achievements.

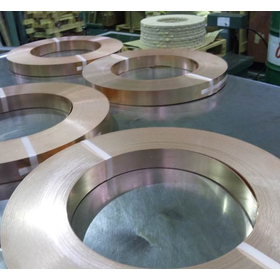

Brass and copper alloy coil materials and plated materials, a supply service that provides the necessary amount of materials when needed through in-house inventory and slitting technology.

Tatsumiya Metal's metal material sales offer high-quality and short delivery times for non-ferrous metal materials and plating materials, thanks to our extensive in-house inventory and slitting equipment, as well as the ability for long-term stable supply. Typically, material supply takes about 1 to 10 days, but at Tatsumiya Metal, we maintain stock and perform in-house processing, allowing for shipment on the same day as the order and delivery the next day at the earliest. (Note: the usual delivery time is 4 to 5 days.) We also accommodate minimum lot sizes starting from 2 kg/mm, responding to various applications and urgency. This reduces inventory risk, allowing for material supply only when needed. Additionally, our strong partnership with manufacturers ensures stable supply. We consider various aspects such as usage frequency, purchase units, inventory burden on our side, and delivery pace together with our customers, aiming for stable supply in all scenarios. 【Features】 ■ Stock of various copper alloy materials and plating materials ■ Integrated supply system with three in-house slitters and partner factories ■ High-quality materials provided through years of slitting technology ■ Stable supply achieved through strong ties with manufacturers *For more details, please download our catalog or contact us.

Inquire About This Product

basic information

【Example of Supply Performance Materials】 ■ Copper: C1020, C1100, C1220, PTC ■ Brass: C2600, C2680, C2801 ■ Tin-plated: C1100, C2600, C2680 ■ Phosphor Bronze: C5191, C5210 ■ Corson-type Alloys: C7025, KA250 ■ Other Copper Alloys: NPZ, 194 series alloys, MOFC ■ Aluminum, Stainless Steel, Titanium, etc. can also be slit 【Processing Range】 ■ Plate Thickness: 0.1mm to 3.5mm (up to 5.0mm at cooperating factories) ■ Width: 5mm to 650mm ■ Tolerance: Width ±0.1mm * Please inquire even if outside this range. 【Delivery Time & Quantity】 ■ Delivery Time: Fastest same-day shipping upon order, next-day arrival. Usually 4 to 5 days after order. ■ Quantity: Minimum lot standard, unit weight 2kg/mm * Small quantity support for prototypes such as several meters or centimeters is possible. * We excel in unit weight splitting and detailed cutting processes! (Example: Dividing a coil of 1c×100kg into 5 parts, 5c×20kg) * For more details, please download the catalog or contact us.

Price information

Prices may fluctuate based on copper market conditions and quantities, so please feel free to contact us.

Delivery Time

P1

Applications/Examples of results

Automotive, motorcycle, and construction machinery parts (bus bars, terminals, etc.), home appliances, office automation equipment, digital devices, low-voltage components, gas appliance parts, semiconductor-related components, heat exchanger parts, clothing parts, spring products, etc.

Detailed information

-

Copper alloy slit coil Copper, brass, phosphor bronze, copper alloy slit coil

-

Copper, brass, copper alloys, phosphor bronze Copper, brass, copper alloys, phosphor bronze slit coil

-

Copper alloy with tin plating Brass with tin plating, copper

Line up(9)

| Model number | overview |

|---|---|

| C2680R | O material, 1/2H, H, EH, plate thickness 0.15 to 2.0 Shipped nationwide by slitting Sample material requests are also accepted |

| C2600 | 1/2H, H, plate thickness 0.4 to 1.0 Shipped nationwide by slitting Sample material requests are also accepted |

| C2801R | O material, 1/4H, plate thickness 0.3, 1.0, 1.2, etc. Stock and slitting options are available |

| Reflow Tin Plating | Brass and copper strips with reflow tin plating. C2600, C2680, plate thickness 0.5, 0.64, 0.8, mm, etc. Immediate slitting available from coil center Prototype requests are also welcome |

| PTC | PTC is an alternative to C1100. Scrap evaluation is the same, and mechanical properties are of the same specifications. The following stock is available for immediate delivery: 【1/4H】0.3 0.5 0.6 0.8 mm, 【1/2H】0.5 0.8 1.0 1.2 1.5 1.6 2.0 3.0 mm, 【H】0.6 mm |

| C1100R | Main stock sizes: 1/4H 0.5 0.8 1.0 mm, 1/2H 0.8 1.0 1.5 2.0 mm, etc. Please inquire about other thicknesses |

| C1020R | Major sizes include 1.0, 2.0, 2.5, 3.0 mm, as well as rare steel types like O material of 0.2 to 0.3 mm. Of course, please inquire about other options! |

| C1220R | Primarily 1/4H 0.2 to 0.3 mm, but please inquire about other options! |

| Phosphor Bronze | Provided by various manufacturers such as JX Metals, Harada Nonferrous Metal Works, Seihou Metals, PMC, etc. |

catalog(12)

Download All Catalogs

Company information

<Metal Materials Trading Division> With a rich inventory and four slitting facilities, we supply from the Higashi-Osaka Coil Center to the entire country. We specialize in the sales of copper alloy materials and non-ferrous metal materials. We are also actively proposing the next-generation copper-aluminum clad material "CCAC" in collaboration with Applied Composite Material Corp. <Metal Processing Division> We excel in processing small quantities of various metal pipes. Our diverse technologies include coil winding, R-bending, various bending processes, and welding. We handle everything from one-off parts used in heat exchanger components and machinery to larger quantities for automotive, consumer, and housing equipment. In the world of bending processing, where small lots are common, the presence or absence of molds becomes quite important. We mix our own molds and equipment with those from partner factories to provide tailored proposals. Additionally, our NC automatic lathe precision cutting processing leverages the procurement advantages unique to Tatsumiya, which has a metal materials trading division, enhancing customer satisfaction through technical expertise, procurement capabilities, and cost efficiency. With over 90 years of establishment as a processing trading company, we view the 100-year mark as a milestone and will continue to build a great company in the future.

![Check the trends of the copper bullion market at a glance! Analysis! [Free graph available]](https://image.mono.ipros.com/public/product/image/9a9/2000242416/IPROS2235627367216692879.png?w=280&h=280)

![[Production examples] Machining of environmentally friendly materials such as lead-free brass.](https://image.mono.ipros.com/public/product/image/5bf/2000435380/IPROS11415096575018895330.JPG?w=280&h=280)

![[Mandatory Compliance] Truck Backup Sonar | Proven track record of 6,000 units installed](https://image.mono.ipros.com/public/product/image/2072982/IPROS1365987416322734488.png?w=280&h=280)