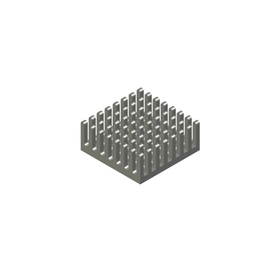

Examples of ultra-small heat sink fins produced through precision and fine press processing.

This is an introduction to a case study of heat sink manufacturing primarily used in IC (integrated circuit) semiconductors. The heat sink is bonded to the lead frame, enhancing the heat dissipation performance of the package. The material of this heat sink is a Cu alloy, with a thickness of 1.0mm or more selected to improve heat dissipation characteristics. The processing precision of the punched parts is ±0.03mm, which is highly accurate. 【Case Study】 ■Product Category: Heat Sink ■Industry: Semiconductor Industry ■Processing Category: Press, Punching, Forming ■Precision: ±0.03mm (punched parts) ■Material: Cu Alloy *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Since our establishment in 1985, our company has consistently engaged in the development, design, and manufacturing of lead frames and mold dies for semiconductors, as well as precision molds. Leveraging the know-how cultivated through years of experience, we provide better products to a wide range of customers. Additionally, we have many qualified personnel and utilize state-of-the-art equipment along with accumulated technical expertise, focusing on high-precision mold processing as our core technology. We aim to actively respond to our customers' needs as a partner in the development, design, and manufacturing of various products. As globalization progresses and overseas competitors continue to grow rapidly, we strive to demonstrate our manufacturing superiority, meet expectations regarding quality, cost, and delivery, and aim to be a company that is needed by our customers, while maintaining a commitment to manufacturing in Japan and continuing our daily efforts.