Utilizing "SolidCAM" and "i-Machining" in the mold industry! Introducing case studies.

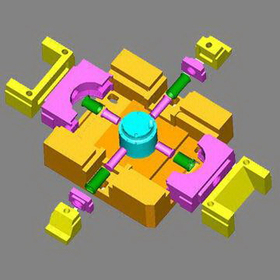

We would like to introduce the case of Kobayashi Manufacturing Co., Ltd., which has implemented SolidCAM. The company, which deals with the design and manufacturing of plastic molds and injection molded products, had already adopted 3D CAD/CAM from other companies. However, to respond to further price competition, they introduced "SolidCAM i-Machining" in the summer of 2013. As a 3D CAM, it has fewer input items and is easy to operate, producing good paths, making it very suitable for first-time users. Additionally, the tool life is excellent, which is appreciated along with the reduction in processing time. 【Case Study】 ■ Kobayashi Manufacturing Co., Ltd. (Shinagawa, Tokyo) ■ Products: Design and manufacturing of plastic molds and injection molded products ■ Implemented Product: SolidCAM i-Machining ■ Implementation Period: Summer 2013 *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Content】 ■ A focus on mold-making since before the war, with a seamless process from design to injection molding ■ Specializing in plastic molding using flame-retardant and non-combustible resins ■ A significant decrease in mold orders and soaring resin prices ■ Competing with Asian companies and accommodating prototype services with 3D printing ■ Aiming for differentiation through further productivity improvements ■ Compared to multiple CAD/CAM systems used so far ■ Actually using "i-Machining" ■ The foundation of Japanese manufacturing *For more details, please refer to the PDF document or feel free to contact us.

Price information

Please contact us.

Delivery Time

※Please contact us.

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Tactex Co., Ltd. has the strength to create and provide new value by combining the manufacturing elements cultivated in the "Factory Solutions" field with the dealer elements in the "Office Solutions" field through its business that spans both areas. To communicate this strength more widely to our customers, we have prepared a practical showroom where you can see the machining process and tours where you can check improvement measures for office environments through implemented case studies. We will continue to strive daily to ensure our customers' satisfaction. *We have many application example videos available on YouTube. https://www.youtube.com/c/TactexFS

![[Case Study] Kobayashi Manufacturing Co., Ltd.](https://image.mono.ipros.com/public/catalog/image_generated/01/142/408229/408229_IPROS8300765061185066997_1.jpg?w=120&h=170)

![Pro Manual! Zero Defect Outflow Countermeasures Quality Improvement Techniques [Complete 8 Series]](https://image.mono.ipros.com/public/product/image/813/2000765622/IPROS35340332026041000038.jpeg?w=280&h=280)