[Published in the Industrial Economic Newspaper] Introducing the development story of the specially shaped wire for protecting optical fibers used in submarine cables.

An article about our "Optical Fiber Protection Specialty Wire for Undersea Cables" has been published in the Industrial Economic Newspaper! In the midst of the recession known as "Iron Cold" in 1984, when our company was still called "Naniwa Seikui," we received an order from a steel trading company in Tokyo requesting, "Please make a fan-shaped specialty wire by splitting a pipe into three vertically." A few days later, President Murao was surprised when he saw the drawings that arrived. It was the first order for a fan-shaped iron wire, and on top of that, they requested a tolerance of within plus or minus five thousandths of a millimeter. At that time in the industry, a tolerance of about one-tenth of a millimeter was the norm, and they were demanding an unprecedented level of precision, with a length of 1000 meters as well. The delivery date was specified for just two weeks later. * The full text is available at the link below. * For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

Related Videos

basic information

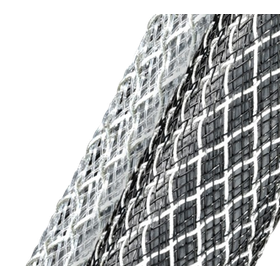

Features of "Specially Shaped Wire for Undersea Cable Fiber Optic Protection" ■ For undersea cables ■ Withstands high water pressure of up to 8000m depth and 800 atmospheres ■ Prevents cable cuts caused by ship anchors, fishing nets, sharks, etc. ■ In the event of an accident on the seabed, prevents seawater intrusion into the cable within 100m *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Purpose】 ■Protection of optical fibers ・High water pressure on the seabed ・Ship anchors and fishing nets ・Cable cuts caused by sharks and other creatures *For more details, please refer to the PDF document or feel free to contact us.

catalog(2)

Download All CatalogsCompany information

Since its establishment in 1947, we have been manufacturing and selling steel wire products through drawing and rolling processes, and now we offer integrated production from cold-formed components to metal parts produced by pressing, shearing, and machining. In particular, we excel in the production of deformed coil wire with irregular cross-sections, and our strength lies in our ability to consistently produce unique deformed metal parts utilizing these irregular wires. Compared to powder sintering and precision casting methods used for manufacturing deformed parts, our deformed metal parts produced entirely through plastic processing at Namitei possess excellent toughness, strength, and smooth surface characteristics, making them widely adopted in sliding components and thin-walled deformed parts. To leverage the cost advantages of continuous processing, we propose specifications that mix functional applications and processing characteristics to meet our customers' needs.