We will continue to challenge ourselves in modern manufacturing together with our customers!

Our company is committed to "modern manufacturing," starting with the production of nails and evolving through various transformations, including the production of copper shaped wires, growing alongside the times. We manufacture a variety of shaped wires with different cross-sectional shapes, as well as related components. Based on the manufacturing technology of shaped wires that we have cultivated over many years, we cater to a wide range of needs, from everyday life-related fields such as automotive, construction, civil engineering, home appliances, and plants, to global and cutting-edge areas like submarine cables.

Inquire About This Product

Related Videos

basic information

【Business Description】 Manufacturing and sales of iron and non-ferrous wire products and metal processed parts 【Product Types】 Iron-based ■ Cold drawn steel wire ■ Deformed wire ■ Parts Copper-based ■ Deformed copper wire ■ Copper parts 【Applications】 ■ Automotive ■ Telecommunications ■ Construction, building materials, and civil engineering ■ Construction machinery, industrial machinery, and plants ■ Furniture and home appliances ■ Others 【Locations and Factories】 7 locations including the head office and factory

Price information

For more details, please contact us.

Delivery Time

※For more details, please contact us.

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

Detailed information

-

1945 Start of the nail manufacturing industry - Signboard from the time of establishment

-

1963 Entered the wire rod field and introduced rolling mills for wire materials.

-

Development of special irregular wires in 1970.

-

Development of a non-standard wire for optical fiber protection for submarine cables in 1985.

-

Automotive-related parts 1992

-

Start of mass production of control equipment-related parts (terminals) in 2002.

-

Start of mass production of precision cutting processing (fine cut) in 2011.

-

2015 Forged parts of irregular shapes

-

Development of irregular copper wire in 2019

catalog(1)

Download All CatalogsCompany information

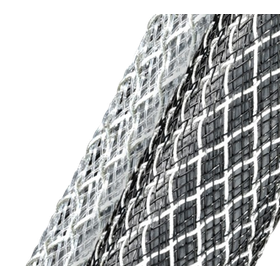

Since its establishment in 1947, we have been manufacturing and selling steel wire products through drawing and rolling processes, and now we offer integrated production from cold-formed components to metal parts produced by pressing, shearing, and machining. In particular, we excel in the production of deformed coil wire with irregular cross-sections, and our strength lies in our ability to consistently produce unique deformed metal parts utilizing these irregular wires. Compared to powder sintering and precision casting methods used for manufacturing deformed parts, our deformed metal parts produced entirely through plastic processing at Namitei possess excellent toughness, strength, and smooth surface characteristics, making them widely adopted in sliding components and thin-walled deformed parts. To leverage the cost advantages of continuous processing, we propose specifications that mix functional applications and processing characteristics to meet our customers' needs.