We provide advanced molds (components) through the know-how we have cultivated over many years and the latest technology.

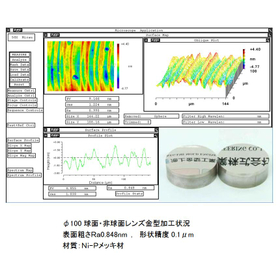

We handle nano-level processing. You can trust us for high-precision processing like that at the nano level.

Inquire About This Product

basic information

- Tool: V90° - Material: Ni-P material

Price range

Delivery Time

Applications/Examples of results

Micro-groove processing

catalog(1)

Download All CatalogsCompany information

- Design and manufacturing of molds for plastic injection molding We manufacture full hot runner molds for syringe outer barrels and will showcase molded products of syringe outer barrels and related mold components. In addition to syringes, we also produce molds for various medical products, caps, lenses, and more. We are capable of ultra-high cycle molding for a wide variety of food containers. We will also display molding samples using our three-layer molding molds. We possess extensive know-how in interior and exterior parts related to home appliances and automobiles. Our technology development group conducts lens processing, fine needle processing, micro-channel processing, and electroforming (electroformed parts and electroforming stampers), and we will exhibit various processing samples. We also accept some nano-level processing. At our parts center, we provide various mold components and sell hot runner systems manufactured by Taiwan Eitom Co. (A-mold). The Chubu Technical Service Center offers the provision of automotive mold components and reverse engineering services such as digitizing inserts. For mold manufacturing/local procurement and maintenance (including molds from other companies) in Japan, Mexico, Thailand, and China, please consult Ikegami Mold Industry Co., Ltd.

![[Free Offer] Prevent Blade Troubles in Production Equipment! Non-Stick Thin Film Coating](https://image.mono.ipros.com/public/product/image/fde/2000612726/IPROS23915370847246220159.jpeg?w=280&h=280)

![[Free Giveaway] Non-Stick Coating | Prevent Blade Troubles in Production Equipment!](https://image.mono.ipros.com/public/product/image/a78/2000619955/IPROS37607432622075090550.jpeg?w=280&h=280)

![[Surface Treatment Case] Surface treatment that streamlines the manufacturing process of lithium-ion batteries.](https://image.mono.ipros.com/public/product/image/604/2000700111/IPROS81671406460541521470.jpeg?w=280&h=280)

![[Surface Treatment Case] Improving Production Equipment for Lithium-Ion Batteries!](https://image.mono.ipros.com/public/product/image/5b1/2000703368/IPROS15171996575415638336.jpeg?w=280&h=280)