Contributing to simplification and efficiency to address labor shortages! Achieving a comfortable environment.

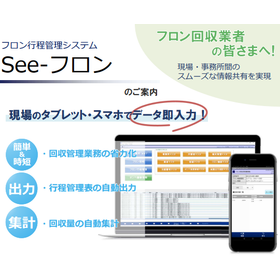

"LinX" is a system that manages the input and output of raw materials and the remaining amount of raw materials during production in real-time, allowing for accurate tracking of current inventory levels of raw materials. It not only manages optimal inventory and the effective use of remaining raw materials but also reduces the burden on operators and raw material management personnel through increased efficiency and labor-saving measures. Furthermore, by standardizing tasks, it provides an environment where anyone can perform the work, contributing to solutions for labor shortages. 【Features】 ■ Real-time management of raw material input and output, as well as remaining amounts during production ■ Accurate tracking of current inventory levels of raw materials ■ Reduces the burden on operators and raw material management personnel ■ Provides an environment where anyone can perform the work ■ Contributes to solutions for labor shortages *For more details, please refer to the PDF materials or feel free to contact us.

Inquire About This Product

basic information

【Benefits of Introduction】 ■ Significant economic impact ■ Ability to aggregate data whenever needed, enabling speedy report creation ■ Actual inventory and inventory records are always in sync ■ Effective management of accurate inventory sheets leads to efficient raw material supply operations ■ Production lines are always tidy *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Factor Co., Ltd. has been continuously engaged in research and development of productivity improvement systems in the paperboard manufacturing industry. With the transformation of IT technology, the utilization of information by companies has become commonplace, and we have consistently pursued innovation up to the present. By "visualizing" and "making visible" the information resources in manufacturing operations, we aim to create a shared understanding within the organization and achieve further efficiency.