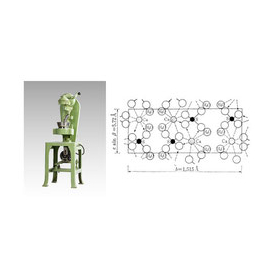

A machine that performs excellent processing through the synergistic effects of dispersion, stirring, crushing, mixing, and kneading! Processing of ceramics, fine ceramics, and rare metals.

**Features** - Maintains the characteristics of the Ishikawa-style mixing and grinding machine, achieving higher grinding performance by forcibly rotating the pestle with a motor. - Suitable for mixing and grinding materials with high viscosity. - The 'AGX series' includes a convenient tabletop model (AGB type) as well as a freestanding model with legs (AGA type). - The tabletop model (AGB type) is suitable for experiments in research and development and can also be used within a draft chamber. - Various materials for the bowl and pestle are available, including agate, alumina, and tungsten carbide, allowing customers to choose materials according to their needs. **Suitable Use Cases** - Used as an experimental machine for research and development, it is employed for grinding (milling) and dispersing small quantities of the following materials: - Ceramic materials such as titanium (Ti), zirconia (ZrO2), silica (silicon dioxide SiO2), alumina (Al2O3), silicon carbide (SiC), and silicon nitride (Si3N4). - Processing of rare earth/high-performance metals such as carbon, iridium, tellurium (Bi2Te3), tin, niobium, tungsten, molybdenum, antimony, platinum, gold, and copper.

Inquire About This Product

basic information

**Features of the Ishikawa Type Stirring and Crushing Machine** The following features are available: (1) Uniform and consistent mixing and crushing treatment within the bowl due to unique design (2) Simultaneous mixing and crushing processing is possible (3) High driving torque allows for processing of high-viscosity materials (4) Lower processing energy compared to ball mills, enabling "mild processing" **Basic Specifications of the Product** - Bowl types: Agate, Alumina, Tungsten Carbide - Bowl inner diameter: Agate: 120mm, Alumina: 120mm, Tungsten Carbide: 140mm - Bowl depth: Agate: 30mm, Alumina: 30mm, Tungsten Carbide: 63mm - Processing volume: 0.05L - AGB type that can be used as an automatic mortar in laboratories - AGA type that is self-standing - The pestle is forcibly rotated by a motor to enhance crushing performance **Introduction to the Testing Laboratory** You can use the experimental machine for free to evaluate the functions and performance of the Ishikawa type stirring and crushing machine. Additionally, our staff, who are well-versed in stirring and crushing processes, will support your experiments based on your requests. Furthermore, we will propose the optimal selection of the Ishikawa type stirring and crushing machine and the stirring and crushing treatment suitable for your processing needs. Please feel free to utilize this when considering your options.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

Detailed information

-

(1) AGA Type (Independent Type) - Pot inner diameter: 120mm - Pot depth: 30mm - Processing volume: 0.05L - Pot materials: agate, alumina, tungsten carbide - Device width: 490mm - Device depth: 410mm - Device height: 1180mm - Power supply: 100V 0.2kW (2) AGB Type (Tabletop Type) - Pot inner diameter: 120mm - Pot depth: 30mm - Processing volume: 0.05L - Pot materials: agate, alumina, tungsten carbide - Device width: 400mm - Device depth: 405mm - Device height: 715mm - Power supply: 100V 0.9kW

catalog(5)

Download All Catalogs

![[Use Case] Example of the use of composite electrodes for lithium-ion batteries: Introduction to the published technical monograph.](https://image.mono.ipros.com/public/catalog/image/01/1a3/739990/IPROS52434389648099151179.png?w=120&h=170)

News about this product(2)

Company information

Our company is a specialized manufacturer of automatic mortar and pestle machines. The features of the automatic mortar and pestle (Ishikawa-style stirring and grinding machine) include the ability to simultaneously perform stirring, grinding, mixing, and kneading using unique technology. It has the following basic capabilities: 1. Uniform and precise mixing is possible - Allows for uniform mixing while controlling particle size. 2. Easy uniformity and control of particle size - Can achieve uniform particle size while finely grinding. 3. Prevents excessive deterioration of materials - Due to low mechanical stress (mild processing energy), it can process while suppressing over-grinding and chemical changes. - High-energy processing (such as ball mills) can cause reaction changes due to heat generation, but temperature management is easier with the automatic mortar and pestle. 4. Suitable for small-scale prototyping and experiments - Ball mills and planetary mixers require large amounts of raw materials, but the automatic mortar and pestle can prototype with a minimum of 0.5g. - Easily adaptable for process scale-up (easy application from small to large scale). 5. Capable of processing slurries, pastes, and high-viscosity materials - The motor torque for the pestle rotation is high, allowing for processing of high-viscosity materials.

![[Case Study] Introduction of the paper using AGA "Mechanochemical Dehydration of Hydrate Crystals"](https://image.mono.ipros.com/public/catalog/image/01/52d/739989/IPROS29414558935298517792.jpeg?w=120&h=170)

![[Comprehensive Catalog] Ishikawa-style Automatic Mortar and Pestle, Ishikawa Factory Co., Ltd.](https://image.mono.ipros.com/public/catalog/image/01/007/759980/IPROS7614596388894315027.jpeg?w=120&h=170)

![Mixer [Vertical Medium Speed Gear Reduction] HP-500](https://image.mono.ipros.com/public/product/image/407/2000572114/IPROS63612516449049089377.jpeg?w=280&h=280)

![Portable Mixer [Drum Lid Attachment] DKS (JIS 200L)](https://image.mono.ipros.com/public/product/image/288/2000572159/IPROS86533879284916870777.png?w=280&h=280)