Simultaneous transfer of various design patterns onto resin molded products.

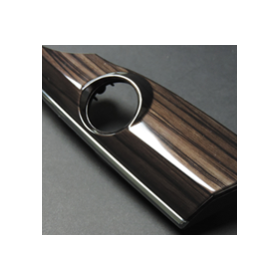

Our company is a plastic injection molding manufacturer specializing in exterior design parts. We handle processing technologies such as 'In-Mold Decoration (IMD)' which involves inserting printed designs on film into the injection molding die and injecting them, thereby transferring them onto the resin surface. 'In-Mold Decoration (IMD)' allows for decoration to be done simultaneously with injection molding, significantly reducing the number of processes and enabling low-cost mass production. 【Features】 ■ Reduces processes such as painting, allowing for time and cost savings ■ Capable of accommodating complex shapes, offering excellent design flexibility ■ Supports a wide range of variations, including chrome-like finishes and surface textures ■ Allows for hard coating treatment simultaneously with molding ■ Reduces the use of organic solvents compared to painting and plating processes *For more details, please download the PDF or feel free to contact us.

Inquire About This Product

basic information

【Other Technologies】 ■ Film insert molding (IML molding) ■ Thin-walled molding ■ Exterior molding ■ Mold processing *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

- Automotive interior control panel - Automotive interior design panel - Car navigation LCD bezel

catalog(1)

Download All CatalogsCompany information

Life Mold Co., Ltd. provides high-quality plastic molded products, including in-mold decoration (IMD molding) and insert molding (IML molding). Additionally, we handle a wide range of technologies, including thin-wall molding technology that significantly contributes to the miniaturization and thinness of products, as well as exterior parts and mold processing. Please feel free to contact us first.

![What is in-mold molding? [Basic Knowledge]](https://image.mono.ipros.com/public/product/image/95f/2001194324/IPROS55683361301375633875.jpeg?w=280&h=280)