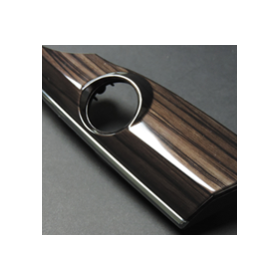

Integrally molded film with rich design features.

This is a method of forming films with printed patterns, such as PC and PMMA, using vacuum forming, where the outer shape is extracted and integrally molded. Compared to conventional press forming, it can accommodate more complex three-dimensional shapes and offers greater design freedom. Additionally, it significantly reduces the labor involved in secondary processes such as painting and printing of the molded products. 【Features】 ■ It is possible to faithfully reproduce complex shapes such as 3D curves in design. ■ Both forming and decoration processes can be performed simultaneously, leading to significant efficiency improvements. ■ It excels in optical properties and wear resistance. ■ A variety of design expressions are possible. ■ It can flexibly accommodate a wide range of small lot productions. ■ Compared to painting or plating processes, the use of organic solvents is limited, making it environmentally friendly. *For more details, please download the PDF or feel free to contact us.

Inquire About This Product

basic information

【Other Technologies】 ■ In-Mold Decoration (IMD Molding) ■ Thin-Wall Molding ■ Exterior Molding ■ Mold Processing *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

- Automotive interior panel - Car navigation LCD touch panel - Home appliance control panel

catalog(1)

Download All CatalogsCompany information

Life Mold Co., Ltd. provides high-quality plastic molded products, including in-mold decoration (IMD molding) and insert molding (IML molding). Additionally, we handle a wide range of technologies, including thin-wall molding technology that significantly contributes to the miniaturization and thinness of products, as well as exterior parts and mold processing. Please feel free to contact us first.