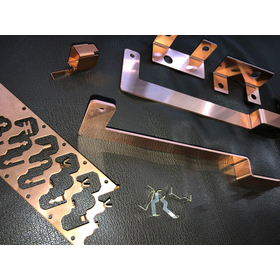

[Production examples] Machining of environmentally friendly materials such as lead-free brass.

Numerous achievements in mass production using lead-free brass and cadmium-free brass bars on NC automatic lathes! The procurement advantages made possible by Tatsumiya Metal, which has the functions of a materials trading company!

Amidst the restrictions on the use of "lead" in various environmental laws and regulations, free-cutting brass containing about 4% lead for the purpose of improving machinability is currently exempted due to the lack of effective alternative materials. However, prompt action is essential towards the eventual lifting of this exemption in the coming years. Additionally, since some users establish their own environmental standards, it is also necessary to be prepared to respond at any time. At Tatsumiya Metal, we can make precise proposals based on our extensive sales record in the materials division, including lead-free brass alloys such as Eco Brass, and our considerable experience and achievements in our machining division. - As a materials trading company, we have a robust material procurement network. - We possess know-how gained from our sales experience with materials. - Plus, we have processing achievements in our machining division! - We have a cooperative system with material manufacturers. - We offer various lead-free copper alloys, including silicon-based and bismuth-based options, as well as low-lead materials (there are systems that add silicon instead of lead and those that add bismuth). We have established a quality system that can meet high technical demands with 45 NC automatic lathe combination machines and high-precision measuring instruments such as roundness measuring devices and surface roughness profile measuring instruments. *For more details, please download the catalog or contact us.

Inquire About This Product

basic information

【Processing Range】 ■Outer diameter 2 to 51mm ■Round bars, hexagonal bars, square bars, special-shaped bars, pipes 【Materials】 ■Brass (Copper alloy) Eco Brass, C3601, C3602, C3604, C3771, C3712, lead-free, cadmium-free ■Stainless Steel SUS304, SUS303, SUS316, SUS430, SUS440C, SUS310, SUS420J2 ■Steel S45C, S45CH, SCM415, SCM435, SCM415N, SS400, SCM435H ■Aluminum A2011, A2017, A5056, A6061, A7075 ■Others Titanium (TB340), Copper (C1020, C1100), Phosphor Bronze (C5441) 【High-Precision Measuring Instruments】 ■Roundness and cylindrical shape measuring machine ■Surface roughness and contour measuring machine ■Measuring microscope/image measuring system ■Image dimension measuring machine 【Secondary Processing】 ■Cleaning, plating, anodizing, heat treatment ■Welding and brazing with other components such as pipes *For more details, please download the catalog or contact us.

Price range

Delivery Time

Applications/Examples of results

[Delivery Achievements] Automobiles, hydraulic control, pneumatic control, aviation, medical, city gas, LP gas, semiconductors, low voltage, solar power generation, and others.

catalog(7)

Download All Catalogs![Case Studies of Precision Machined Parts [A Cutting Manufacturer with In-Depth Knowledge of Materials - Tatsumiya Metal]](https://image.mono.ipros.com/public/catalog/image_generated/01/266/350929/350929_IPROS1113235389997356725_1.jpg?w=120&h=170)

Company information

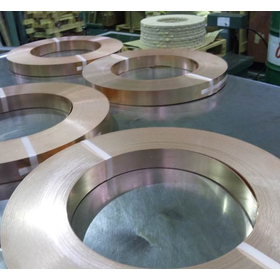

<Metal Materials Trading Division> With a rich inventory and four slitting facilities, we supply from the Higashi-Osaka Coil Center to the entire country. We specialize in the sales of copper alloy materials and non-ferrous metal materials. We are also actively proposing the next-generation copper-aluminum clad material "CCAC" in collaboration with Applied Composite Material Corp. <Metal Processing Division> We excel in processing small quantities of various metal pipes. Our diverse technologies include coil winding, R-bending, various bending processes, and welding. We handle everything from one-off parts used in heat exchanger components and machinery to larger quantities for automotive, consumer, and housing equipment. In the world of bending processing, where small lots are common, the presence or absence of molds becomes quite important. We mix our own molds and equipment with those from partner factories to provide tailored proposals. Additionally, our NC automatic lathe precision cutting processing leverages the procurement advantages unique to Tatsumiya, which has a metal materials trading division, enhancing customer satisfaction through technical expertise, procurement capabilities, and cost efficiency. With over 90 years of establishment as a processing trading company, we view the 100-year mark as a milestone and will continue to build a great company in the future.

![Check the trends of the copper bullion market at a glance! Analysis! [Free graph available]](https://image.mono.ipros.com/public/product/image/9a9/2000242416/IPROS2235627367216692879.png?w=280&h=280)