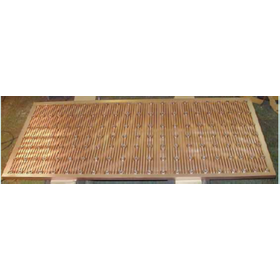

We design and manufacture copper plates in various sizes, including slabs and blooms!

Our company designs and manufactures molds for continuous casting, as well as maintenance and design and production of peripheral equipment. We provide a comprehensive service from the new design and manufacturing of back frames and copper plates to surface treatment and assembly. We also install items such as thermocouples. 【Manufacturing Examples】 ■ Mold copper plates - design and manufacturing ■ Beam blank copper plates - design and manufacturing ■ Mold equipment - design and manufacturing ■ Billet equipment - design and manufacturing ■ Tundish manufacturing, etc. *Please feel free to contact us for more details.

Inquire About This Product

basic information

【Equipment】 ■ Five-sided machining center (Mitsubishi Heavy Industries) ■ NC surface grinding machine * Curved processing possible ■ NC horizontal lathe (Toshiba Machine) ■ Vertical machining center (Osaka Kiko) ■ 500-ton distortion correction press (Murai) etc. * Please feel free to contact us for more details.

Price range

Delivery Time

Applications/Examples of results

For more details, please feel free to contact us.

catalog(1)

Download All CatalogsCompany information

One of the main processes at the steel mill is continuous casting, which involves creating steel slabs of a specific shape during the solidification of molten iron. Our company designs, manufactures, and maintains the core equipment, including molds and surrounding facilities. Please feel free to contact us if you have any inquiries.