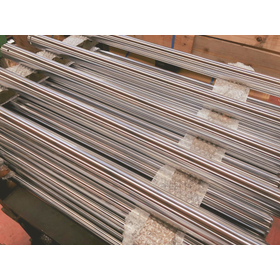

Skilled in processing sizes up to 3,000 mm × Φ70, such as hydraulic cylinders (hard chrome plating).

At our main factory, we produce 100,000 rods and 500,000 small items of hard chrome plating per month, while our second factory handles individual hard chrome plating. Regarding quality, we have digitized data on hard chrome plating solutions, bath temperature, electrical quantity, time, etc., and established a unique automated line that does not rely on craftsmen's hands. We have developed technology and systems to process long metal rods into perfectly round and uniformly hard chrome plated products using vertical input automatic machines and plating tanks.

Inquire About This Product

basic information

[Solving Issues with Hard Chrome Plating] - Prevention of Thickness Variation Established technology and systems for processing long metal rods into perfectly round and uniformly hard chrome plated products using vertical automatic machines and plating baths. - Prevention of Quality Variation Digitized factors such as hard chrome plating solution, bath temperature, electric quantity, and time, and built a unique automated hard chrome plating line that does not rely on craftsmen. Additionally, maintained stable pre-plating quality through multi-process bulk buffing using continuous automatic buffing machines. - Environmental Considerations through Plating Solution Regeneration Impurities that significantly affect the quality and corrosion resistance of the plating film accumulate in the plating solution. By removing these impurities to stabilize quality and achieving the regeneration treatment of chrome plating wastewater containing harmful waste, we have reduced environmental impact. - High Performance Developed a vertical hanging plating line capable of accommodating general-purpose products, allowing for high adaptability and achieving short delivery times with small-batch production of various products. - Response to Customer Needs Responded to customer requests by exchanging product data via email and accommodating various packaging, loading styles, and wrapping requests, including products exported directly overseas from Yamawori Ken.

Price information

- How the price of hard chrome plating is determined: The price is based on the surface area of the product being plated, measured in decimeters (the area of a square with sides of 10 cm). The unit price per decimeter is calculated considering factors such as the type of material, size, length, weight, shape, film thickness, whether masking is required, the number of orders, production cycles, and indirect costs like transportation. - The price of hard chrome plating at Sanwa Riken: The price for plating treatment typically ranges from 120 to 400 yen per decimeter. Due to the production capacity and productivity characteristics of Sanwa Riken's hard chrome plating production line, the unit price per decimeter for products measuring approximately 1000 mm to 2000 mm in length and with diameters of Φ20 to Φ40 is relatively low.

Delivery Time

P2

Applications/Examples of results

Numerous achievements in various industries with hydraulic cylinders and pneumatic cylinders: - Industrial machinery manufacturers - Forklift manufacturers - Automobile manufacturers - Tool manufacturers - Jig and fixture manufacturers

Company information

Sanwangi Riken is a specialized company in Nagoya that focuses on "hard chrome plating." In particular, we process 100,000 shafts per month and excel in processing sizes up to 3,000 mm × Φ70. In addition to hard chrome plating on outer diameters, we also focus on inner diameters, plates, irregular shapes, and buff polishing, responding to our customers' stringent demands. Located in the heart of Japan, we are just 2 minutes from the IC, making transportation convenient, and we receive orders for "hard chrome plating" from manufacturing companies nationwide.