Centerless grinding and surface grinding of unstable-shaped products and ultra-high precision products.

We achieve the processing of unstable shapes that are thought to be impossible with centerless grinding, as well as ultra-high precision mass production with an outer diameter accuracy of ±0.5μ!

Our company has 30 years of experience specializing in grinding processing. From this experience, we excel in centerless grinding of difficult-to-process items such as thin materials, D-cuts, and unstable shapes, as well as ultra-high precision mass production with an outer diameter accuracy of ±0.5μ. We own 45 centerless grinding machines, enabling us to produce over 10 million pieces per month. For surface grinding, we utilize rotary grinding and double-sided grinding. We guarantee precision in perpendicularity to the outer diameter and achieve parallelism through simultaneous processing of both end faces. Furthermore, we can provide integrated production from material cutting and chamfering to end face grinding and outer diameter finishing. If you have any issues with grinding processing, please feel free to contact us.

Inquire About This Product

basic information

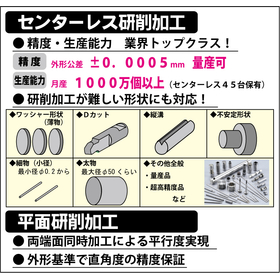

◇Centerless Grinding <Features> - Capable of centerless grinding for typically difficult-to-process unstable shapes - Achieves ultra-high precision machining with an outer diameter processing dimension tolerance of ±0.0005 mm - Capable of producing over 10 million units per month (with 45 machines) - Consistent production from material cutting → chamfering → end face grinding → outer diameter grinding finishing is possible <Precision> Outer diameter tolerance: Mass production possible at ±0.0005 mm Surface roughness: Can achieve 0.0001 level Roundness: Below 0.0005 <Processing Diameter> Minimum diameter from 0.2 to 50 <Work Materials> SUS, iron, BS, titanium, Kovar, aluminum, and others ◇Flat Grinding <Features> - Supported by rotary grinding and double-sided grinding - Right angle based on outer diameter - Parallelism achieved through simultaneous processing of both end faces <Productivity> Monthly production of over 1 million units

Price information

I will provide a quote.

Delivery Time

Applications/Examples of results

Acquisition of ISO 9001:2015 Certification Certified Supplier Recommended by DENSO

catalog(2)

Download All CatalogsCompany information

Miyazaka Industrial Co., Ltd. is a precision parts manufacturing company focused on centerless grinding. Since 1990, we have started our business primarily processing dot wires used in dot printers. Since then, we have been specializing in the processing of ultra-fine wires and centerless grinding, always striving to acquire new technologies. Currently, we have achieved a minimum diameter of φ0.3, an outer diameter processing dimensional error of ±5/10,000, and a surface roughness of 0.1s with a mirror finish. Additionally, we are engaged in product development and manufacturing sales under our own brand "Kokkun," including a one-touch oil filling valve that can be easily attached when dividing liquids from pails or one-gallon cans without leaking or dripping, as well as a cock for kerosene cans and an emergency water purifier.

![[Processing Example] Surface Grinding](https://image.mono.ipros.com/public/product/image/88b/2000777948/IPROS63744023635121394133.png?w=280&h=280)

![If it's oil | Generator engine oil [JPG ZERO] Generator](https://image.mono.ipros.com/public/product/image/eb1/2000852308/IPROS30478244085557726193.png?w=280&h=280)