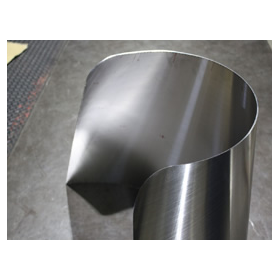

Multiple examples of manufacturing using a roll bender, including processes that do not allow for shock lines, R-shaped processing, punching materials, and opening materials without irregularities!

This document summarizes examples of production using the roll bender from Nishiguchi Bender Co., Ltd. It introduces processing techniques that do not create shock lines on R-shaped parts, as well as processing of punching materials and opening materials without unevenness, illustrated with photographs. Our company is capable of manufacturing equipment and machine parts for various industries according to customer orders. [Examples Featured] ■ Material: SPCC 2.0t ■ Material: SUS304 Punching 2.0t ■ Material: SUS304 Inner #400 3.0t ■ Material: SUS304 Both #400 3.0t ■ Material: SUS304 2B 3.0t ■ Material: Crimped Mesh 25 8.0t *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(4)

Download All CatalogsCompany information

At Nishi-guchi Vendor Industry Co., Ltd., we operate as "the JOB SHOP for professionals," primarily engaged in can manufacturing and precision sheet metal processing. We particularly excel in difficult processing items inspired by L bends and R shapes, with a wealth of processing experience. In recent years, we have also actively tackled complex can products that combine bending and welding. We can manufacture equipment and machine parts for various industries according to customer orders. Please feel free to contact us first.

![[Business Introduction] Bending Processing](https://image.mono.ipros.com/public/catalog/image/01/d53/458712/IPROS15845429282337516870.jpg?w=120&h=170)

![[Business Introduction] Bending Processing](https://image.mono.ipros.com/public/product/image/219/2000437101/IPROS14786022564004447499.jpg?w=280&h=280)

![[Video Available] Introduction of Bending Processing Case 9](https://image.mono.ipros.com/public/product/image/834/2000284412/IPROS9120275201084677128.JPG?w=280&h=280)

![Press Brake [Introduction to Bending Processing] *Free materials available](https://image.mono.ipros.com/public/product/image/960/2000435459/IPROS11298299800539328742.PNG?w=280&h=280)